US $50,000.00

| Condition: |

Used: An item that has been used previously. The item may have some signs of cosmetic wear, but is fully

operational and functions as intended. This item may be a floor model or store return that has been used. See the seller’s listing for full details and description of any imperfections.

...

|

Brand | Gerber |

Directions

Similar products from Cutting & Finishing Equipment

Fabric Cutting Machine Shear 220V 65mm Cloth Cutter Free ship Fedex EMS

Tidland Class III Knife Holder

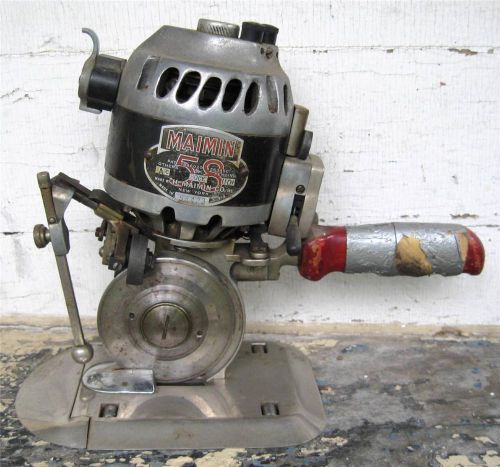

Vintage Maimin 58 A C Industrial 110 Volt Fabric Cutter

Eastman Cloth Cutting Machine Industrial 110 Volts Fabric XB 2486

EASTMAN BB FABRIC CUTTER ELECTRIC

SUPRENA HC1007A HANDHELD CLOTH CUTTING KNIFE TEXTILES PRODUCTION EQUIPMENT

New WD-1 Handheld Electric Cutter

Maimin Cutting Machine 1-1/2" Sharpening Stone #381A For Round Cutting Machines

4" fabric end cutter machine up to 96" across ,semi automatic complete set 110v

Blade Sharpening Stone for Maimin "Mini-Shere" Handheld Electric Cutters

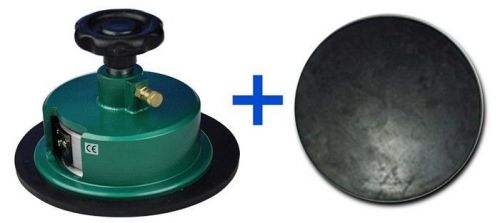

Fabric Sampler Cutter For Determining GSM in fabric + rubber pad ship from USA

Cloth/fabric Spreader Machine ,Expandable 48" to 72",complete set ship from USA

Rollem feeder Champion 990 Series

Beaver Industrial Rotary Fabric Cutter

Eastman 534 Round Knife Cutting Machine NEW!!

Eastman 548 Round Knife Cutting Machine NEW!!!!

Eastman Brute 8" Cutting Machine Brand New!!!

Eastman BBB32 Round Knife Cutting Machine BRAND NEW!!!

HDX 10214X 10220X 14-20 in Manual Ceramic Tile Cutter pkg of 7

People who viewed this item also vieved

Spinning Machine bobbin guide brush holder / M8

lot of UNION SPECIAL binding cutter knife blades & parts

Mist Lubrication Mist Coolant System for CNC Lathe Milling Drill Machine

Sutton and Landis shoe machine etc shoe machine grinding and waxing wheels

WHITE NYLON B69 SEWING THREAD 4oz SPOOLS BONDED #69 " USA MADE" T-70 NEW SPOOL

600 yards 1 inch GOLD Polypropylene Webbing

300 yards 1 inch PINK Polypropylene Webbing

300 yards 1 inch DARK GRAY Polypropylene Webbing

SINGER 111W155 WALKING FOOT - VERTICAL BOBBIN HEAVY INDUSTRIAL SEWING MACHINE

TOYOTA HEAVY DUTY ZIG ZAG SEWING MACHINE DENIM CANVAS LEATHER VINYL UPHOSLTERY

COLLECTIBLE 1924 SINGER INDUSTRIAL SEWING MACHINE PACKAGE...

Morgan 4 head hp plotter.gerber,80 in accumark,lectra,optitex,velocity compatabl

Vintage United Carr Industrial Rivet Grommet Eyelet Press M369

S91 SPENCER GERBER VACUUM BLOWER

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies