US $980

| Condition: |

New other (see details): A new, unused item with absolutely no signs of wear. The item may be missing the original packaging,

or in the original packaging but not sealed. The item may be a factory second, or a new, unused item with defects. See the seller’s listing for full details and description of any imperfections.

...

|

Brand | Greenheck |

| MPN | 11809423 0908 | ||

| Model | VK-H-12-M30-X | ||

| Country/Region of Manufacture | United States |

Directions

Similar products from Blowers & Ventilators

Fasco 70626007 Furnace draft inducer blower 115V U62B1

Dayton hvac or dust blower 3c540

ARMSTRONG - ASTRO 250ss - CIRCULATOR 110223-308 ***1 Year Warranty***

York Furnace main blower fan assembly 120-240V 1 HP Genteq motor Eon HD01 module

Fantech FR250 In-line Exhaust Fan 10" Duct

Fantech FR225 In-line Exhaust Fan 8" Duct

TRANE / FASCO INDUCER ASSY, X38040252017, 1/50hp, 208-240V, 3000RPM

GREENHECK 24" TUBE AXIAL INLINE PAINT BOOTH EXHAUST FAN TBI-CA-3H24-5

Fasco Inducer 7021-8735 P/N 1708-607

Fasco Inducer 7002-2792 P/N 1010975P

Fasco Inducer 702110218 P/N 44431-001

Fasco Inducer 7021-10046 P/N 40425-002

Fasco Inducer 7021-8657 P/N 20J8101

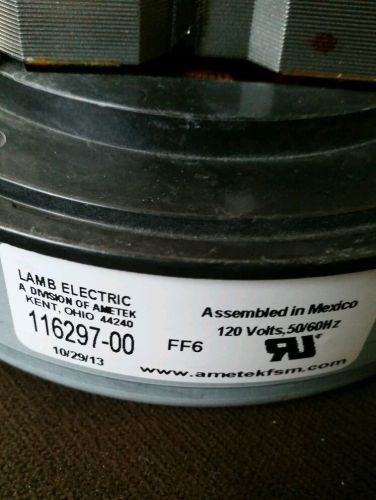

Lamb Ametek Blower Motor Fortis Mosler Automated Banker

Fasco Inducer 7021-8693 P/N 1006168P

Fasco Inducer 7021-8428 P/N 21D330673

GENERAL GP8 GAS POWERED BLOWER VENTILATOR W/ HONDA 4.0 ENGINE, and BLOWER HOSE!

People who viewed this item also vieved

BEAMEX PGXH Hydraulic Calibration Pump with Case

Suntec J4PB-B1000G Single Stage Oil Pump 1725 or 3450 RPM, RH Rotation #289

PLENUM PLUS Commercial Grade Series of Condensate Pumps, Model: A2X-1965 DV

Danfoss Commercial Compressor #HRM045U4LP6 380- 415 V

New Sporlan Catch-All Filter Drier C-163-S 3/8" ODF SOLDER 16 cu in desicant NOS

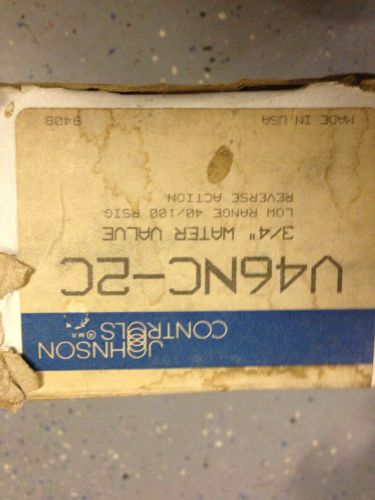

Penn water regulating valve V47NC-2C

White Rodgers 36E97 type 201 Furnace LP Gas Valve

Honeywell VR8200H 1012 Furnace Pilot Gas Valve Nat Gas

Honeywell V8043E1012 3/4 " Zone Valve – VALVE ONLY (No Powerhead) -- New/unused

NuTone 0696B000 Motor Assembly (Motor Number JA2C394N)

Marathon Carrier 5K49QN3204AS, HD52AR465, 460V, Condenser Motor New

Electromode 5262-C Thermostat Circuit Switch Temperature Control Relay

Legacy 24 x 24 x 12 Extended Surface Rigid Cell Filter, LG-904-PH, MERV 15

New Rheem Ruud RXGY-F18 90 Plus Furnace High Altitude Pressure Switch Kit

Thermo King 1/2 hp 460V 3 phase Motor

Carrier Bryant 312131-701 for 580A 584A 48N 58SXA080 heat exchanger kit

Johnson Corporation Heat Exchange 2800 SNH Type 2800SNH

American AB-1604-B6-FP Shell & Tube Brass Heat Exchanger 4-Pass 150-300 PSI 300F

NIB New Alerton IBEX TUX-653P Digital Controller

BELIMO AF24-SR DAMPER ACTUATOR 24VAC/DC 133"lb 50/60 HZ 6W

Honeywell DeltaNet MicroCel Controller R7516B-1007-7 24V 50/60HZ

HONEYWELL T498B 1512 LINE VOLT ELECTRIC HEAT THERMOSTAT

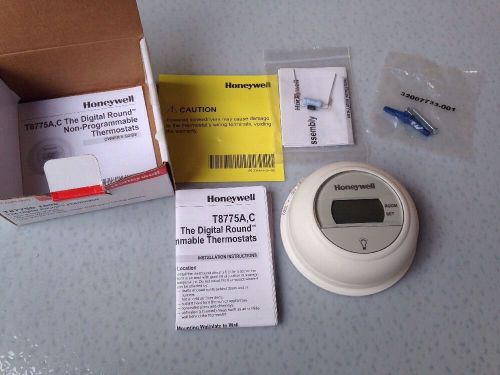

Honeywell T8775C 1005 Digital Round Thermostat T8775 (8026)

Honeywell T874C1000 Heat Cool 24V Control 40-90F Thermostat NEW

Rheem SP20172 Flammable Vapor FV Sensor Kit Water Heater Heating Cooling Tank

Siemens RS540 Electronic Room Sensor

Fireye 4-314-UV2 Single Burner Flame Scanner 45UV5 Series

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies