US $3200

Directions

Similar products from Other Pump Machinery and Parts

Crane Deming Pump, model 5M 6", SS Shaft And Impeller

3hp industrial pump 230/460v #1085S

3hp industrial pump 230/460v #1084S

3hp industrial pump 230/460v #1083S

Action Pump Co. ACT-SS-55, FM Approved Stainless Steel Pump

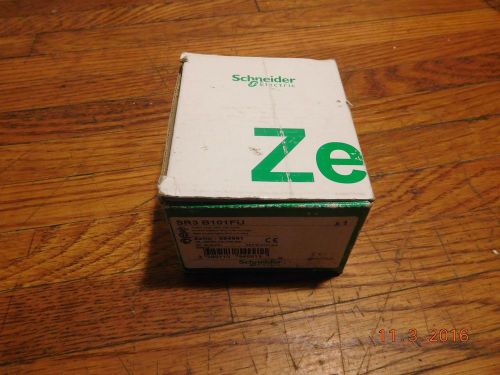

Schneider Electric Logic Relay SR3B101FU 100-240VAC Zelio 054991

State DR2000 Time Based Dosing System DR2000/115V

Used - BIF Proportioneers Chen-o-feeder Metering Pump, Model: 1271-13-9122,

Walchem Chemical Metering Pump EWB16F1-FC 1.0 GPH, 105 PSI Solid Pump!

Advantage Controls Chemical Metering Pump B130X1-KFCV 1.25 GPH @110 PSI STRON

NEW Nikkiso HT25D-C4 Non-Seal Canned Motor Pump 428 GPM P1-100001-028

Walchem Chemical Metering Pump EZB11D1-VCA 0.6 GPH @ 110 PSI Ready to go!

NEW Penguin Filter Pump 1.5 HP

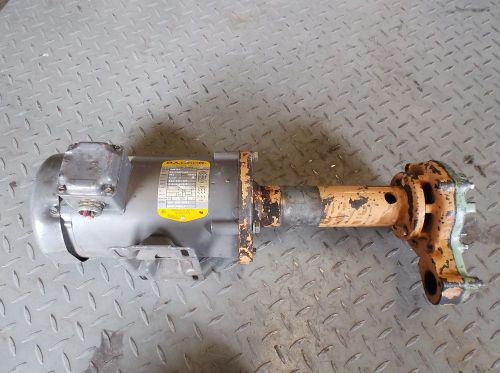

SUCTION PUMP W/BALDOR 1-1/2 HP MOTOR, 3450 RPM, 208-230/460 VOLT, 3 PH (USED)

Bell & Gossett 616PF Pump with Marathon Electric BM0045 Motor

PUMP, CENTRIFUGAL 2" INLET/OUTLET, 80FT MAX HEAD, 130 GAL PER MIN.

PUMP, CENTRIFUGAL 3" INLET/OUTLET, 80FT MAX HEAD, 220 GAL PER MIN.

LMI Milton Roy Chemical Pump 1.6gph

People who viewed this item also vieved

149010 New-No Box, Casappa PLP20.8D0-31S1-LOC/OC-N-EL FS Hydraulic Gear Pump

"SIMPLEX" # P-82 Hydraulic Manuel Pump.

ENERPAC TURBO II AIR DRIVEN HYDRAULIC PUMP 10000 PSI PATG-1102N & 6' HOSE

Prominent Griffco 3/4" NPT 7302211 PTFE Back Pressure Valve - NEW

LOT 24 NEW WAUKESHA 57-15 GASKET 3-1/2X4X1/4IN D330764

LOT 19 NEW WAUKESHA N70240 3-3/4X4X1/8IN PUMP O-RING D330758

NEW GAST D334H 9IN LENGTH PUMP ROTOR REPLACEMENT PART B287489

Jabsco 6YF98 Electric Drum Pump Motor 600 Watts 3/4 HP

BELL & GOSSETT 111061 POWER PACK MOTOR 1/6 HP 1725 RPM 115V SERIES 100 2" HV B&G

Grundfos SPK4 Immerseble pump,Baldor motor,Milling machine,110/220V

Mini Micro Priming Gear Water Pump DC 3V-12V RS-360SH Spray Motor new

Wilo Submersible Electric Well Pump (2707267)1HP NPT 1-1/4 3Wire 230V 1Ph *NEW

Little Giant WRSC-6 506065 Sump Pump System- 1/3 HP 1-1/2" Outlet FREE SHIPPING

Sewage Pump 4/10 Hp SC440110T Pentair Water Sewage Pumps SC440110T

Craftsman Submersible Portable Utility Pump - 1/4 Horsepower1,800 GPH IB

QTY2 Lot Medo VP0625-V1014-DS-0511 Vacuum Pump 115V 1.4A 161W

WELCH VACUUM PUMP With Emerson Special Service Duty 1/2B HP Motor 115V 1725 RPM

PRO-SET CPS VPC4SU 1 STAGE VACUUM PUMP

GAST 1531-107B-G557X Motor Mounted Rotary Vane Pump Vacuum Compressor Industrial

Irrigation and Landscapers "Suck Tube" - Sprinkler Repairs, Plumbing, Boaters!

New 2" Parker Thoro-Braid air water petroleum hose #7251 150' roll

ITT G30 BELL & GOSSETT 1-1/2 IN X 1-1/2 IN CENTRIFUGAL PUMP B226121

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies