US $690

Directions

Similar products from Chart Recorders & Loggers

MO274 ASTRO-MED INC DASH4 CHANNEL CHART / DATA FIELD RECORDER

GOULD TA550 PORTABLE CHART RECORDER

GOULD TA 2000 TA2000 CHART RECORDER

TEAC MR-40 CASSETTE DATA RECORDER WITH REMOTE CONTROL UNIT ER-85

CAVITRON GRAPHIC PLOTTER MODEL GP-20

YSI YELLOW SPRINGS INSTRUMENTS MODEL 81A RECORDER

BuchiGlasUster Reactor Motor VAFU 71 4B 7 12467

BARNSTEAD LINEAR CHART RECORDER MODEL LR92925

7465:Dickson:TH8-76:Chart Recorder

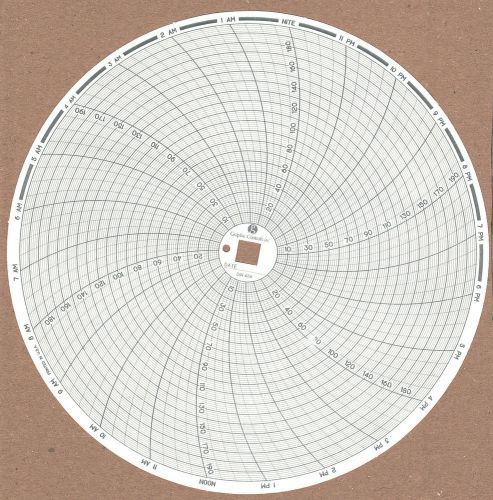

Replacement for C456 24-Hour 0 - +200° F 8-inch Chart for Dickson ET8, TH8, PR8

Yokogawa uR100 Chart Recorder - Model 4153 - 115VAC

JEWETT WEKSLER INSTRUMENTS CORPORATION 08M1D5B

COULTER PLOTTER AUTOMATIC PARTICLE SIZE DISTRIBUTION ANALYZER MODEL J

Instron Recording Chart Paper 3710-022 (9 rolls)

NEW Premium Instrument Co 5-Pack 2nd Position Red Pens 82-88-0202-05 *FREE SHIP*

Mitsubishi MD3000 HS-MD3000U(2) S-VHS ET VCR Video Cassette Recorder Ultrasound

Dickson Temperature & Humidity Chart Recorder TH800

People who viewed this item also vieved

Milwaukee pH600 Digital pH Tester/Meter/Pen

DENTAL Lab Equipment Getidy Dental 23L Steam Autoclave Sterilizer Class B JQA-23

Labconco Steam Scrubber Model 4400300 - Powers up as shown.

HEIDOLPH Laborota 4010 Evaporator Waterbath + Rotovac Vacuum Pump # 7120

Labnet Vortemp 56 Dual Microplate Shaking Incubator #2

WEBBER STANDARD GAGE 0.1008" BLOCK AS IS BIN#31-34

AmScope B120C Siedentopf Binocular Compound Microscope

MICROSCOPE PART RUSSIAN FILAR EYEPIECE + RETICLE OMO MOB-1-16X OPTICS BIN#A7

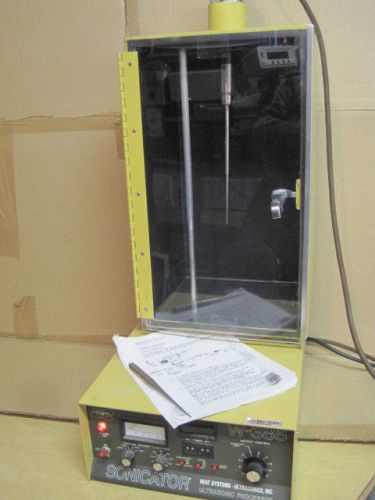

Ultrasonic Homogenizer Sonicator Cell Disruptor Mixer Noise Chamber & Two Probes

Parker-Daedal Linear Translation Stage w/Starrett Micrometer

Alloy Products Corp Stainless Steel 316L Pressure Vessel 12"x36" Nice! 165 PSI

Vision Engineering Alpha Mantis Microscope 120 VAC 60 Watt Power Source Supply

Varian Turbo-V450 A Turbomolecular Pump For Parts/Rebuild Only

Scientific Industries Vortex Genie Model K-550-G

Glas-Col GKH Reversible GT Motor Control with Glas-Col 099D GT31 Stirrer #3

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies