US $570

| Condition: |

Used: An item that has been used previously. The item may have some signs of cosmetic wear, but is fully

operational and functions as intended. This item may be a floor model or store return that has been used. See the seller’s listing for full details and description of any imperfections.

...

|

Brand | Hakko |

| MPN | Japan | ||

| Model | 456 | ||

| Country/Region of Manufacture | Japan |

Directions

Similar products from Soldering Irons & Stations

Soldering Gun 230V 30W 130W Soldering Iron CTLP130 Welding Tool EU Free Shipping

Soldering Iron Heat Gun Car Adapter 30W 12V Cigarette Lighter Plug Free Shipping

Soldering station Easy-98 Adjustable 20-48 watts 200-450 °C Free Shipping

Edsyn Loner 902 100W Dual Soldering Station with Atmoscope 930 Hot Air Ion #01

Hakko 472D Desoldering Tool, Used, No card, No Iron, Warranty

Metcal MX-RM3E Soldering and Rework Hand-Piece for MX-5000 and MX-5200 Series

HELPING HAND THIRD HAND TOOL MAGNIFIER SOLDERING JEWELRY HOBBY WATCH

T862 REWORK STATION INFRARED SOLDERING SMT SMD IRDA BGA WELDER MACHINE

2pc HAKKO 900M-T-LB SHAPE-LB Soldering Iron Replacement tips kit with pen shape

AMERICAN BEAUTY 9301 Solder Pot Heating Element

Weller WRS 2000 Repair System + HAP1 Soldering Tip Cooper Tools GmbH Free SH

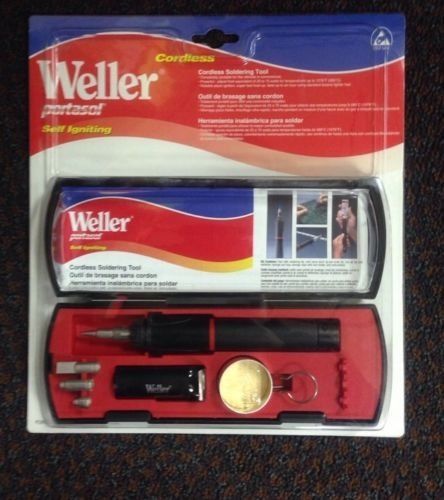

WELLER PORTASOL P2KC (SELF LIGHTING) CORDLESS SOLDERING KIT

Soldering Board 6in X 6in - SOL-400.10

WELLER SOLDERING IRON 80 WATT HEAVY DUTY USA #SP80 120 VOLT NIB

Two pack of 0.8mm Dia Lead Free Soldering Wire 33G 1oz 33feet Rosin core

Veecome New 0.5MM Diameter Solder Flux Soldering Tin Lead Wire 0.5mm Solder Wire

AMERICAN BEAUTY 550 Watt Soldering Iron Electric CASTOMATIC SOLDER Big LOT 550W

People who viewed this item also vieved

Vacuum De-solder Gun Desoldering Pump Remover Tool for Solder Desolder Removal

Solder paste indium and multicore brand. For dispenser, 25g in tube.

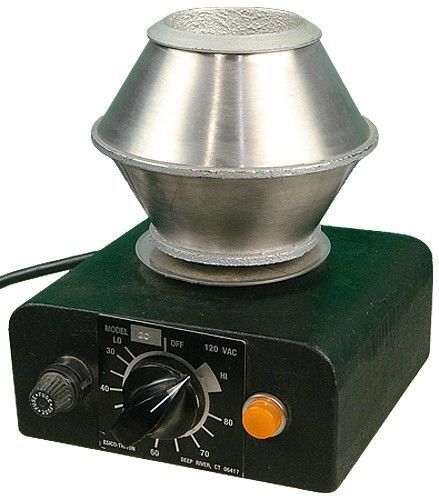

Esico-Triton 20 Soldering Lead Melter

50m 0.08-0.1mm Super Fine Steel Wire for LCD Screen Separating

New 4 in 1 Soldering Solder Iron Tip Cleaner Brass Sponge and Holder

New Welding Soldering Solder Iron Tip Cleaner Cleaning Steel Wire W/ Stand YUUS

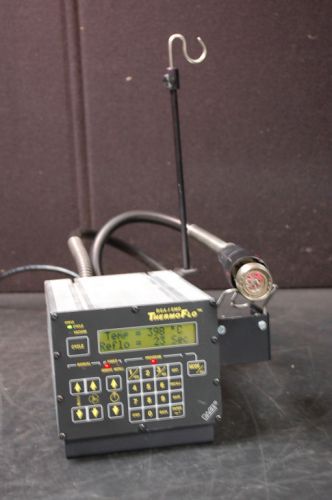

PACE PPS 95 BGA/SMD Thermoflo Solder Rework Station (incomplete)

Vintage Luxury Shoulder Bag Faux Rabbit Fur Khaki Color w/Tassel Decors Tote Bag

4 LB 4 ROLLS SOLDER Kester "66" 60/40 RESIN CORE FLUX CORE DIA .093 FRY Metals

Soldering Repair Solder Paste Cream Hot sell Welding Seal Grease Tools New 50g

50g Silversmith Job Soldering Silver Accessory Solder Paste Hobby

Do it best silver lead free solder 3.2 oz plumbing solder spool

Lead for Soldering Solder 4 Rolls Apx. 3-4 Lbs Different Gauges

New 1 LB Qualitek 50-30021 Roll of Solder Wire 60/40

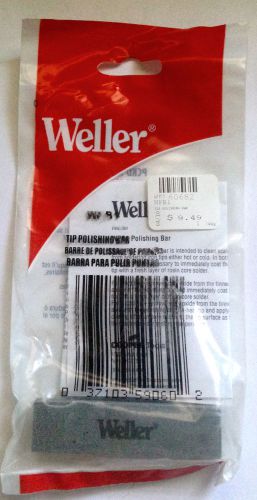

Cooper Weller WPB1 Polishing Bar for Soldering Tips - Removes Surface Oxides NOS

1/4" 16G 24pcs Blunt Stainless Steel Dispensing Syringe Needle Tips

Blunt stainless steel dispensing syringe needle tips 1/4" 16Gauge 120pcs

New Weller CT6F6 600° 3/8" Screwdriver Tip for W100PG & W100P3 Soldering Irons

New Weller CT5A7 700° 1/16" Screwdriver Tip for W60P & W60P3 Soldering Irons

Weller MTG20 Nozzle Width: 9.53mm CHISEL Tip l NEW

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies