US $99.99

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | ZXMT |

| Applications | shoes,sneakers,high heels, raincoats,leather items | ||

| Model | Leather Cobbler Shoe Repair Machine | ||

| Accessories | Shuttle, Needles, Coils, Rod, Machine Stand | ||

| MPN | SF-SKU111 | ||

| Size | As picture show | ||

| Type | Dual Cotton Nylon Line Sewing Machine | ||

| UPC | Does not apply | ||

| Class | Textile & Apparel Equipment | ||

| Manufacturer Part Number | SF-SKU111 | ||

| Bundle Listing | No |

Directions

Similar products from Sewing Machines & Tools

*USED* 6943-UNIVERSAL-PATTERN & CLOTH WEIGHT (3lbs. 11oz, 9"x 2 3/8") FREE SHIP*

*NOS* 136889-SINGER-SPREADER-FOR SEWING MACHINES-FREE SHIPPING*

*NOS* 93499-YAMATO-PRESSE FOOT LIFTER LEVER STOPPER-FOR SEWING MACHINES*

puritan sewing machine low post

JUKI DDL-8700 and 8700H Industrial Lockstitch Sewing Machine head only

Singer 7468 Fully Electronic Sewing Machine w/ 140 Stitch Functions Excellent Ou

Industrial Sewing Machine Light & Thread Spool Holder.

Reese Button Hole Machine Co. Cast Iron Sewing Machine Thread Spool Holder

EUCOMAC ITALY 127-00-1CD-30 seial#678116

Shoe Repair Machine Hand Cobbler Sewing Machine - Cotton Nylon Line Manual

used industrial sewing machine

Vintage CONSEW 75C Industrial Sewing Machine - FOR PARTS NOT WORKING SEE NOTES

Lewis 150-5 Blind Stitcher Blindstitcher with Table

United States Blind Stitch Corp Blindstitcher 99-PB1 with Table

*NOS* 35884D-UNION SPECIAL-GASKET-FOR SEWING MACHINES-FREE SHIPPING*

*NOS* 90814-YAMATO-TENSION SPRING-FOR SEWING MACHINES*

*NOS* 175142-SINGER-PULLEY SHAFT-FOR SEWING MACHINES-FREE SHIPPING*

PFAFF 938 Zig Zag Lockstitch Puller Reverse Industrial Sewing Machine Head Only

VINTAGE Remington (CA) Heavy Duty Sewing Machine *PINK*

People who viewed this item also vieved

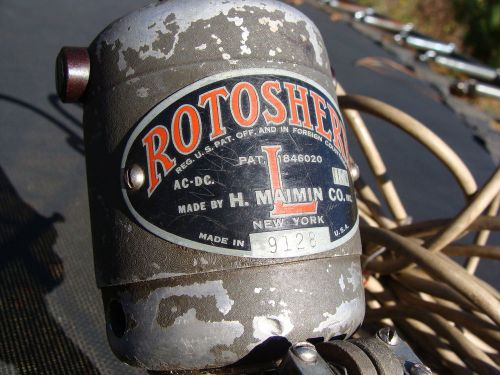

Rotoshere High Speed Fabric Cutting machine, Made in USA Vintage Cool Dangerous

SuLee RC-280 4" Round Knife Fabric Cutting Machine with spare blade

MCGILL INNER RACE PRECISION BEARING MI-14. MB2

TORRINGTON FAFNIR BEARINGS 207PP. MB2

TORRINGTON FAFNIR BALL BEARINGS 205KDD. MB2

TRW MRC BEARINGS 209SFF 0051 01L0A. MB2

Industrial steam iron - ECOSTEAM NOS

Drawing Warping Machine Russell Mfg. Middletown, Ct. 1921 No.165AB 47" x 31"

Vintage Industrial Stainless Steel Sock Form Mold Heating 44"

Automated Components Pocket Press

45I-BSR20-WHT Webbing Plastic 3/4" Buckle (one set as pictured) for Strap 20mm

New Upholstery Hog Ring Pliers Tool With Fastener Clip Set Chain Link Fence

8/9oz(3.2-3.6mm)Natural Vegtan Tooling Belt Holster Shoulder Leather-13-14sq ft

Multiple colors #69 Bonded Nylon Thread - 4 - 8 oz.

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies