US $33.99

Directions

Similar products from Flaps

Yellow Jacket 21485 60" 3-Pak (21060, 21425, 21465)

Yellow Jacket 22660 60", Red, Plus II 1/4" Hose w/ Sealright Fitting

Yellow Jacket 69067 Optional Ball Valve 1/8" NPT F X 1/4" F Flare

Yellow Jacket 15212 12", Plus II 1/4" Heavy Duty Hose w/ Hcl Straight X 90 deg

ROBERTSHAW 720-406 Gas Valve, Fast Opening, 150, 000 BtuH

New! New! New! White Rodgers VR8305m4066 Gas Valve

J/B INDUSTRIES A31484 1/4 MPT x 5/16 OD TUBE CONNECTS - (5 Pack) New

Rheem 110-251F Taco Freedom Flange-3/4" FLANGE

Holby 2" Thermostatic Tempering Valve (Low Temperature) - HTV200LT

Sporlan BBIZE-6-GA, Thermostatic Expansion Valve

ASCO SOLENOID VALVE 8311B30G 12 V 1/4'' NEW IN BOX

ASCO SOLENOID VALVE 1/2'' CAT # 8210G002 NEW

SIEMENS OPENAIR ACTUATOR 24V, 160 IN. LB 0-10VDC GCA161.1P *NEW IN BOX*

NEW Siemens HVAC Actuator SKD62U 599-03205 3 Way Valve 1-1/2"

New Mueller Induestries Ball Valve 1 5/8 ODS

Supco BPV31 Bullet Piercing Valve NEW 1/4", 5/16" & 3/8" tubing

NORTH AMERICAN MFG 3/4" NPT ADJUSTABLE GAS BUTTERFLY VALVE 1122 *NOS*

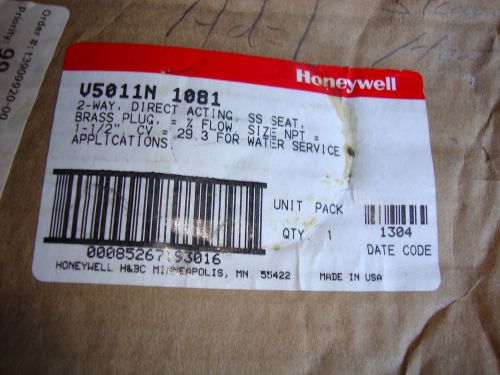

NEW HONEYWELL V5011N 1081 2-WAY 1 1/2" NPT BRASS GLOBE VALVE V5011N1081

People who viewed this item also vieved

Siemens 540-100 VAV Controller/Terminal Equipment Controller

HOLLAND GL1 COAL FURNACE TEMP LIMIT BLOWER CONTROL L492 HONEYWELL

Johnson Controls Metasys FEC MS-FEC1610-0

Karl Klein DNG 13-150S Low-Pressure High Performance Fan 10HP 394112 CF/Hr 15"SP

Carrier / RCD 50DK502898 Fan Shaft

Lennox 41G51, LB-54482C Blower Shaft

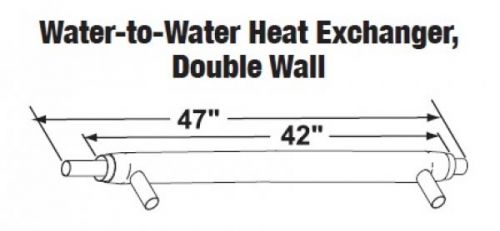

Water-to-Water Heat Exchanger, Double Wall

AMERICAN INDUSTRIAL AQ-15-3 EXP HEAT EXCHANGER TRANSFER 300 PSI 400 DEGREES

Carrier ECM blower motor #HD44AE116

5 5/8" universal blower motor mount wire belly band 3 legs 1/4" Bolts 48 Frame

EVAPORATOR MOTOR 110V- 16/70W 0.95A CLASS B 1450 RPM with BLADE AND BASE

SD) New HVAC Parts... White Rodgers Automatic Pilot 3046-5

39004 MARS SPDT Change Over Switch REPLACES HONEYWELL L6076A

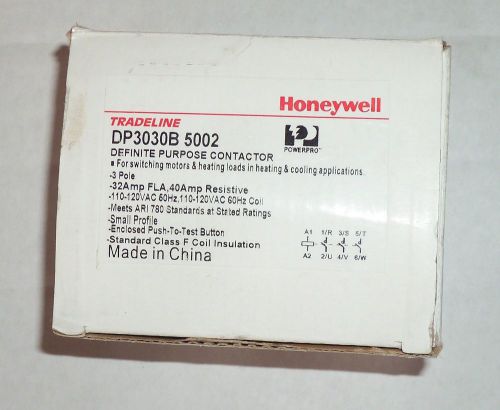

Honeywell Tradeline DP3030B 5002 Contactor 3-Pole HVAC Part 30A 110/120V COIL

Elepon SL-150N Sealess Centrifugal Pump (PUM1211)

Steck Weatherproof Outlet, S-4547/S4547, 60A, 7H, 480VAC

Steck Weatherproof Outlet, S-3246/S3246, 250V, 30A

Uniweld RMC2 "R" Series Acetylene Regulator w/2 Gauges

Uniweld RO "R" Series Oxygen Regulator with 2 Gauges

ALCO ADK-164 Dri-Kleaner Refrigerant Filter Drier

GENERAL ELECTRIC SWITCHGEAR / CHARGING MOTOR PART # 0177C2164G001

HONEYWELL PNEUMATIC DAMPER ACTUATOR PART # MP918B 048 2

NIB . Universal Parts (Honeywell) Ignition Control Kit PN: S8610H1079 . VV-1052

White Rodgers 1C74-51 Staging Thermostat/Low Voltage 1H/1C New In Box

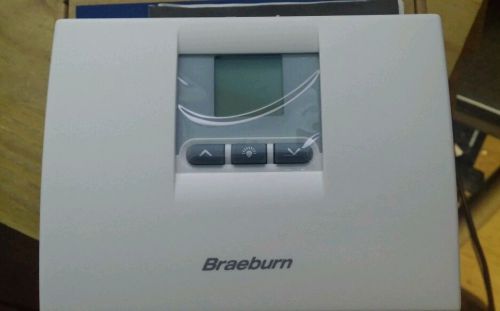

Braeburn 1200 non programable ,2heat,1cool thermostat

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies