US $35.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Type | PLC |

Directions

Similar products from Programmable Logic Controller & Contol Systems

Gatan Model 600-43 MK2 Dual AutoTerminator for Ion Mill Electron Microscopy

NEW MULTIVAC 86.850.0801.00 KUHNKE PCB CIRCUIT BOARD MODULE TIMER B236210

Omron C200H PLC Output Module C200H-OD215

NORDSON MODEL PC40AC PART 131709H *USED*

BENTLY NEVADA FIELDMONITOR PROXIMITOR INPUT MONITOR 1701/15 170115

BENTLY NEVADA 170180-03-00 PIEZO VELOCITY SENSOR I/O MODULE 1701800300

NEW NORDSON 272385B SOLENOID INSTALLATION KIT B287581

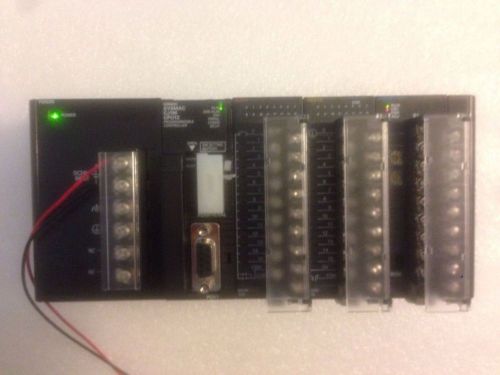

Omron PLC CJ1M-CPU12, ID211, OD212, AD081-V1

NEW PARKER FRICK AFS SAFETY RELIEF VALVE 564790

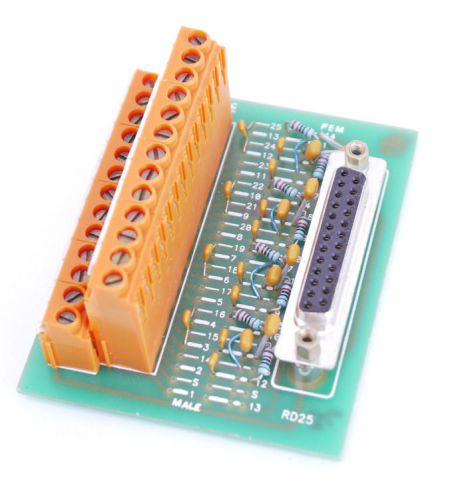

Weidmuller WTI-89020/67 RD25 Port Terminal Module Board Card Assembly Unit

NI SCXI-1000 AC Chassis 2x 1125 2x 1305 2x 1349 Modules National Instruments

NORDSON 24VDC POWER SUPPLY PS40 131739H

NEW ALLEN BRADLEY 1336BDBSP49D GATE DRIVER PCB CIRCUIT BOARD B425856

BRISTOL BABCOCK CONTROLWAVE MICRO ANALOG OUTPUT MODULE 396603-01-7 B(S20-3-31A)

NEW TEXAS INSTRUMENTS 505-6408 8 CH WORD OUTPUT MODULE D379035

NEW BANNER QM42VP6AFV150Q PHOTOELECTRIC SENSOR 10-30V-DC 5-150MM D234621

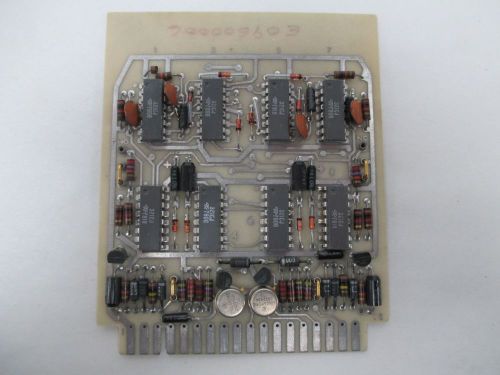

NEW BETA 304340-2D1C PCB CIRCUIT BOARD REV E D329680

HONEYWELL 08631800 MEASUREX DETECTOR FAST PBS LEAD SULFIDE B SENSOR B424931

NEW ALLEN BRADLEY 1492-ACBH1 1P 6A AMP 277V-AC CIRCUIT BREAKER B286242

People who viewed this item also vieved

Westinghouse Motor Circuit Protector 3 Pole 600 VAC HMCP003A0C Set Trip 30Amp DC

13.56MHz PN532 NFC RFID Card Readers Module 3.3V For Arduino Raspberry Pi

HONEYWELL 922AA2BM-A9N-L PROXIMITY SWITCH SENSOR B275454

HONEYWELL HUMIDITY SENSOR H7080B3102

800H-HR2 ALLEN BRADLEY 800HHR2

MICRO SWITCH 6PA19 LIMIT SWITCH WHISKER 0P

New Swagelok Ultra High Purity Diaphragm Valve 6LVV-DPFR4-P-C #W7

NEW NUMATICS 153SS432K000030 120V-AC 1/4 IN NPT SOLENOID VALVE D374993

Kessler Ellis HB1710 Hour Meter 120VAC

Hecon Corp G0-404-190 Counter 6 Digit

9 inch CRT for Proto Trak 3 control

New Allen Bradley 2711-M3A19L1 /A FRN 4.20 PanelView 300 Micro RS-232/DH-485

COOPER POWER SURGE ARRESTER VARISTAR MOV 10KV MCOV8.4 DISTRIBUTION CLASS AZL1B10

INGERSOLL RAND 39875570 *NEW IN FACTORY BAG*

1734-AENT I/O Ethernet Allen Bradley

Allen Bradley SLC500 1746-BAS/C BASIC Module. Nice Used 2006

ROBOTIKITS ATTACKING INCH WORM, EDUCATIONAL ROBOT MINI SOLAR KIT

NEW UNUSED Fanuc Cable A660 2005 T924

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies