US $72.05

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

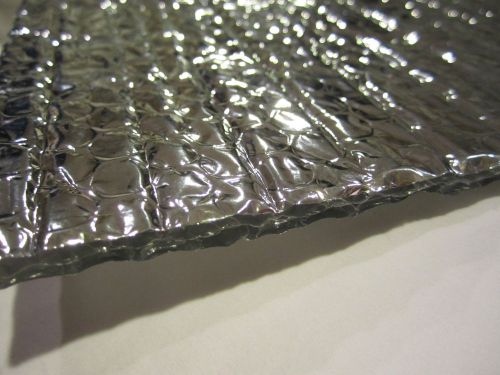

Brand | InfraStop IS™ Reflective Vapor Barrier |

| MPN | IRRBIS48125S | ||

| Model | IRRBIS48125S | ||

| Country of Manufacture | United States |

Directions

Similar products from Weather & Acoustic Insulation

Grace VYCOR ALL Purpose Flashing 9" x 50'

2meters Insulation foaming pipe for hot water inner diameter 25mm thickness 20mm

Bosch i-Boxx72-10 W/ Set 10 for use W/ Click and Go Storage System

Bosch L-Boxx-3D Storage Box W/ Space for Removable Drawers

Bosch L-DOLLY for use W/ L-Boxx Click and Go Cases, Part of Click and Go Storage

Liquid Foil Spray Radiant Barrier Paint Coating 5gal - LOCAL PICKUP ONLY

320' X 2-3/16" COMMERCIAL HEAVY DUTY 2-SIDED ADHESIVE TAPE *FREE SHIPPING USA*

InfraStop IS™ Reflective Vapor Barrier Solid 1000 ft?, Made in USA, Tearproof

RadiantGUARD® ULTIMA foil insulation radiant barrier 1000 sf roll Radiant GUARD

T6-8 JUST RELEASED BOSTITCH COMPRESSION TOOL

PEX Tubing Reflective Underlayment Solid 1000 sq/ft Increases Efficiency!

RadiantGUARD® ULTIMA foil insulation radiant barrier 500 sf roll Radiant GUARD

Thomas and Betts 4" Nylon Insuliner Sleeves 431 NIB Box of 5

Tripolymer Injection Foam Insulation Equipment Standard Dealership Package

Radiant Barrier - Foil Bubble Insulation - 16,000 square feet

2-1/2" WIDE X 29' ROLL 3/4" SPONGE INSULATION ADHESIVE TAPE *FREE SHIPPING USA*

***NEW*** 2" WIDE X 50' ROLL 1/4" BLACK FOAM INSULATION ADHESIVE TAPE

Refillabe Spray Foam Equipment - Model 777

People who viewed this item also vieved

(10 pc) *NEW* Three 3-Way Decora Rocker Switch Ivory Decorator Device 15A 15 Amp

10 ROLLS of 2" x 110 yards Clear 1.7 Mil Uline Economy Tape Packing Shipping

Halo 5" & 6" White LED Retrofit Recessed Lighting Baffle Trim RL560WH-R

80W Bright Pure White 6000K LED Flood Light Garden Wall Wash Lamp 110V-265V

SALE ON NAILS SIX POUNDS OF 20d GVC Sinker nails

Steel Roof Truss for 26' for Hay Barns, Horse Stalls, Agriculture, Pole Barn

ONE - Acanthus Traditional Fireplace Capitals- 7" x 9" x 9"- # FC1-RW

ONE -English Romanesque Fireplace Corbel- 7-1/2" x 8" x 36"- # FCOR4-RW

Geocel 3300 Professional Grade Polyurethane Sealant 10.1oz. Tube

22"W x 22"H Round Louver, Functional Item #: FRLV22

NEW FAN #11509591804 151/2 INCH IN SIZE

KENT Premium Quality 4" WET Diamond Polishing Pad, 4mm Thick, Grit 200, Granite

KENT Premium Quality 4" WET Diamond Polishing Pad, 4mm Thick, Grit 1500, Granite

CRL Combo Switch Acrylic Mirror Plate - Clear

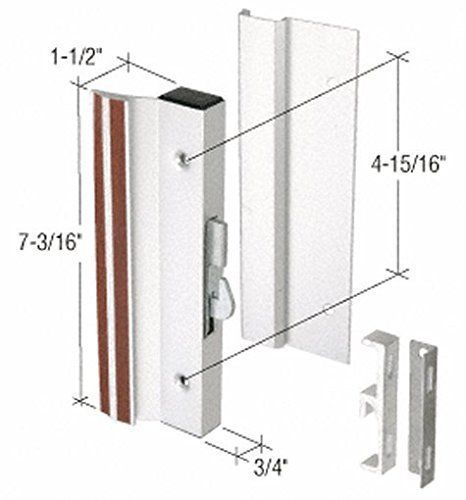

CRL Aluminum Standard Profile Hook-Style Surface Mount Handle C1000

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies