US $9,999.00

| “All functions tested operate normally. Comes with 30 Day Right of Return if not 100% Happy with your purchase. Some Label/Sticker residue, dust, dirt, and possibly some pen marks may also exist. None of which effect the items functionality.” |

| MPN | Paragon 98 |

| Brand | BTU |

| UPC | Does not apply |

Directions

Similar products from Burn-in Power Supplies & Other Equipment

HAKKO FR-870B Pre Carbon Heater Pre-Heater 100V 2-pole Carbon Heaters from Japan

G176815 Micro Instruments CH-700 Dual Stack Burn-in Oven

BLUE M 1100 DEGREE INERT GAS OVEN / FURNACE MDL 20" X 20" X 24" ID IGF-7780F-3

R136204 Tegal Plasmaline Barrel Etch Plasma System

Wavelength Electronics FPL-250 Laser Driver Used

HAKKO FR-870B Pre Heater Pre-Heater Carbon Heaters from Japan

General Scanning Inc Hi Mark 400 Marking Laser, 1064 NM

QTY. 31 POWER ONE LMS 3 X 300 WATT LM5 2000 POWER SUPPLY RACK SETUP

Burn-in Oven chamber Micro Instruments Co CH700 PE9000

Astec PSE6-300-034A Circuit Board Power Supply Burn In

Espec ESS 72-210JW Environmental Stress Screening Test Chamber "We Discount%"

Baxter Scientific Products DN-63HI Inert Oven "Ask us for a Discount%"

Despatch EC307 Environmental Test Chamber -73C To 177C LN2"Ask us for Discount%"

Envirotronics ESS ET63 Enviromental Stress Screening & 30HP 1-Stage Compressr Pk

Sigma Systems C4 Environmental Chamber "Ask us for Discount%"

Grieve AA-500 Industrial Laboratory Oven "Ask us for Discount%"

Tabai HROV82-315-PSLATCH AC Temp/Humidity Chamber W/PS Rack And Driver Cage

Tabai PR-4G Platinous Rainbow 85C/85%RH Trmperature And Humidity Chamber

People who viewed this item also vieved

Ion Systems 22" 5685 AeroBar Ionizer Bar for Anti Static Environments

HEPA-PLEAT II Lab filtration unit, works great!

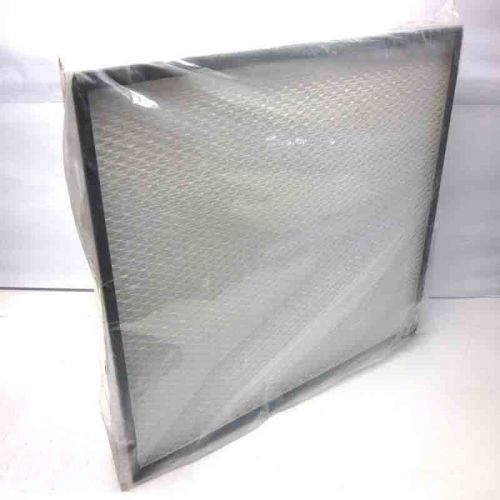

Flanders Laminar Flow Grade VLSI 0-009-4-19-04-SU-00-F2-M-GP HEPA Filter

Hepa Corporation HEPA-PLEAT II D32.2824.28E112F2 1/2S Air Filter #3000-00149

Vision Engineering MICROSCOPE ILLUMINATOR FIBER LIGHT LAMP

VISION ENGINEERING MANTIS MICROSCOPE WITH STAND

VISION ENGINEERING MANTIS MICROSCOPE STAND

VISION ENGINEERING MANTIS FX BASE

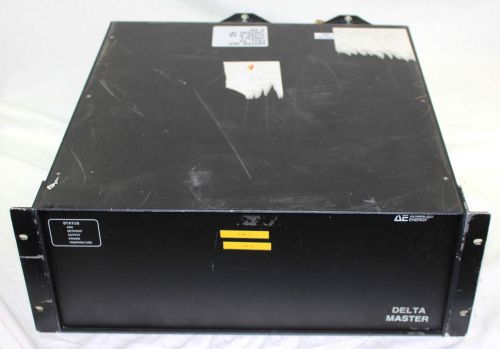

AMAT, AE Advanced Energy, 20KW MASTER PS PASSIVE MDX-20KW MASTER, 3152194-013W

FAV Fast Acting Valve for LAM 9600 or a LAM 9400

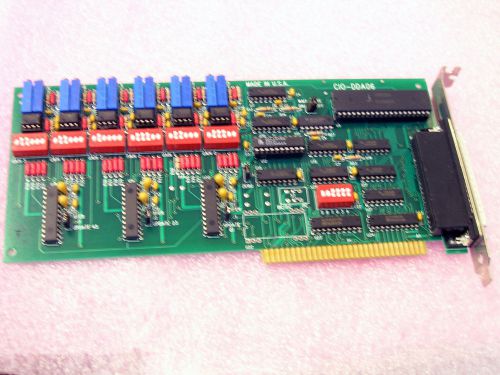

Omega Analog Ouput Board 6 Channels CIO-DDA06

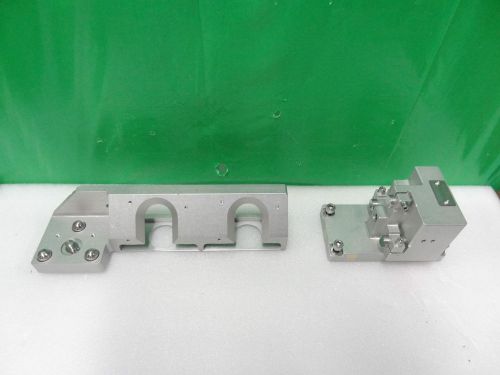

APPLIED MATERIALS OBJECTIVE BS ASSY 0010-G2020 Y5551

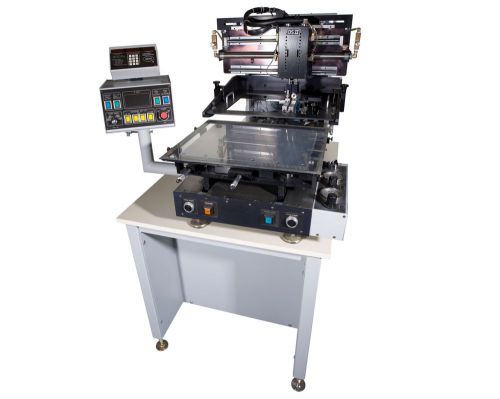

HMI/AMI-Presco 1205 Solder Paste Stencil Printer SMT Circuit Board Semi-Auto

Fancort Model 80 Karry-All ESD Safe Adjustable PCB Board Carriers 18-3/4" x 14"

MPM Tactile Sensor Assembly for UP2000 Stencil Printer Speedline Technologies

Tyco Press BMEP-5T Bench Top Connector 5 Ton SMT PCB Tons

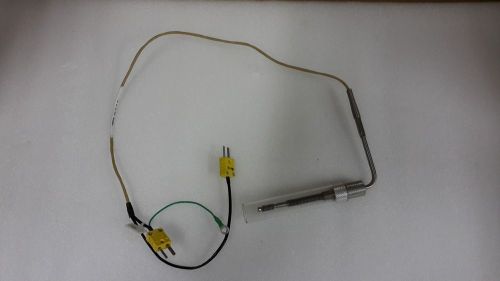

AMAT 1310-01059 TC PROBE, DUAL CIRCUIT, K-TYPE, TFE-INSUL ROOF

CSM FILTER SPLIT BOX 0090-B0090 019

APPLIED MATERIALS 0150-G0640 CABLE OP. CONS EMO OP. CONSOLE I/O PNL.-EMO(OC1)

APPLIED MATERIALS 0150-D4771 XDC5 J1 AIR/VAC BOX to XDC5 J1 J2 CABLE

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies