US $500

Directions

Similar products from Carbide Inserts & Face Mills

10PCS CNMG120408-PM YBC251 + MCLNR2020K12 (1PCS)

10PCS CNMG120408-PM YBC251 + S25S MCLNR12 (1PCS)

10PCS CNMG120408-PM YBC251 + MCKNR2525M12 (1PCS)

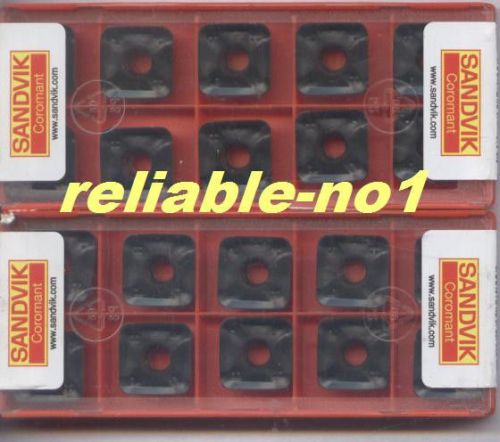

100 PIECE SANDVIK R390-170408M-PM 4240 CARBIDE INSERTS (02)

100 PIECE SANDVIK N123H2-0400-0004-TF 1105 CARBIDE INSERTS (01)

ISCAR INSERTS SDMT 1205PDN-RM-M IC328 20 pcs

-SHIPPING IS FREE - ISCAR WNMG 06T304-NF (WNMG 3-1-NF) IC 807 20pcs

SANDVIK 490R-140408M-PM 4240 NEW MILLING INSERTS ***FREE SHIPPING***

FREE SHIPPING SANDVIK 490R-140420M-PM 4240 20pcs

Kennametal CCGT 2152-LF KC730 Carbide Inserts (QTY of 4) (L630)

Iscar ANKT 1404 PNR IC328 Carbide Inserts (10 NEW Inserts) (C911)

* FREE SHIPPING * SECO 16NR 1.5 ISO-A1 CP500 20pcs -THREADING INSERTS

60 VBMT 331 GP CA5515 CARBIDE KYOCERA INSERTS ( VS Iscar, Kennametal, Sandvik)

Greenleaf LNES-335A G-53 Carbide Inserts (QTY 5) (O 778)

MANCHESTER 510136 C5 CARBIDE INSERTS, QTY 10

30pcs.SANDVIK DNMG 443-MR 4235 or 150612-MR 4235

SECO XNEX 080608TR-MD15 MP3000 - 10 Inserts

Seco 38467 LCGA 130302-0300-FG CP500 Carbide Inserts

Sandvik R390-17 04 08M-MM 2030 Carbide Milling Inserts (4 New Inserts) (O 840)

People who viewed this item also vieved

Keyway Broach Bushing Guide, Type F, 3 7/8" x 5", Uncollared, Used

Keyway Broach Bushing Guide, Type F, 3 3/8" x 6", Uncollared, Used

CNGA543T0820 CERAMIC KY3000 KENNAMETAL Indexable Turning Insert

DNGA434T KY3000 KENNAMETAL CERAMIC KYON TURNING (PROFILE) INSERTS

Machinist Lot Of 12 Hs End Mills 1/4" To 3/4" Diameters

11/32 X 3/4 X 2 1/2 3 Flute Hss Altin Coated (endmill)

1-3/4"x3" Cutting Depth HSS Annular Cutter with 3/4" Weldon Shank, #2083-2033

5 Pcs 1-1/8 x 3" Cutting Depth HSS Annular Cutter+ 1 Pc Pilot Pin, #2083-2023PIN

Old Forge 1977 6 Inch Taper Punch Sharp Point

Adjustable Metal 55mm Diameter Die Handle Round Stock Holder FTH

TAPERED REAMER 2 PIECE SET CHIRE888

Vintage KEYSTONE 12" LONG, 1 11/32"-1 17/32" Expansion Reamer

2 NEW LENOX JIGSAW BLADES 486J MADE IN USA BI-METAL

Slitting Cutter HSS 3"dia. x 1/8"thk x 1"shaft

LOT OF 4 SKF-DORMER LATHE CUTTING TOOLS CARBIDE - 1/2" SHANK

Pratt and Whitney/ Borite boring bit lot -USED

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies