US $120

Directions

Similar products from Carbide Inserts & Face Mills

SANDVIK N151.2-A250-60-4G New Carbide Inserts Grade 1125 7pcs M

SANDVIK R166.0G-16UN01-110 New Carbide Inserts Grade 1020 8pcs M

SANDVIK R166.0G-16UN01-140 New Carbide Inserts Grade 1020 7pcs M

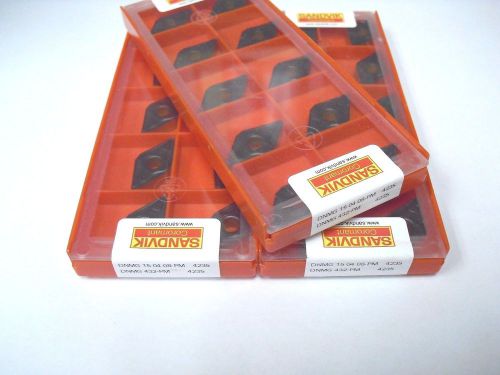

DNMG 432 PM 4235 SANDVIK Insert

345R 1305M-PM 1030 SANDVIK Insert

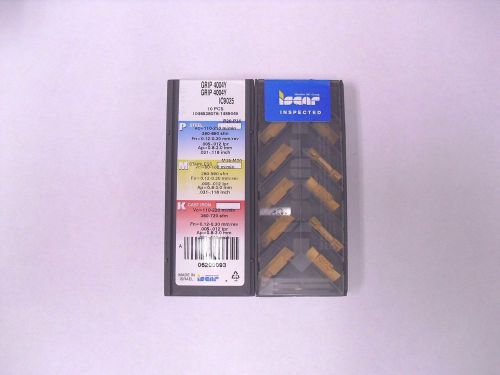

GRIP 4004Y IC9025 ISCAR Insert

6 KENNAMETAL CARBIDE INSERTS XCGT05T3 083DT KC810 STK3583

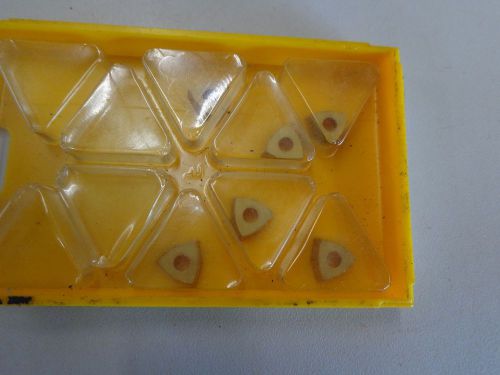

10- KENNAMETAL carbide inserts TPG 221, TPGN 110304, Grade K68 **NEW**

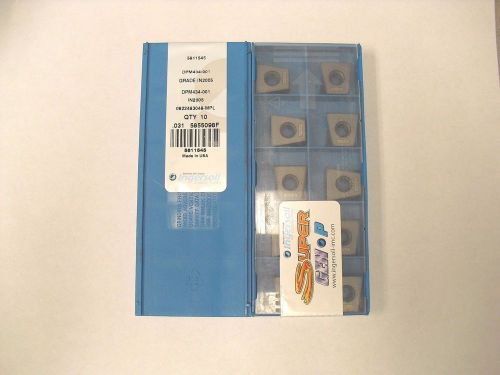

DPM 434-001 IN2005 Ingersoll Insert

10 PC CNMG 433MJ US905 MITSUBISHI INSERT **NEW**

10 PC CNMG 433MJ VP05RT MITSUBISHI INSERT **NEW**

Walter Tiger-Tec P28477-3 WKP35 Carbide Inserts 10 Inserts 457635-787

10 SANDVIK CARBIDE INSERTS TLG-3088L 1125 10 NEW INSERTS

5 NEW KENNAMETAL TOP NOTCH SOLID CARBIDE INSERTS DWG 244406R01

5 pack DNMG 433K Kennametal KC910 Carbide Inserts DNMG433 diamond shape lathe

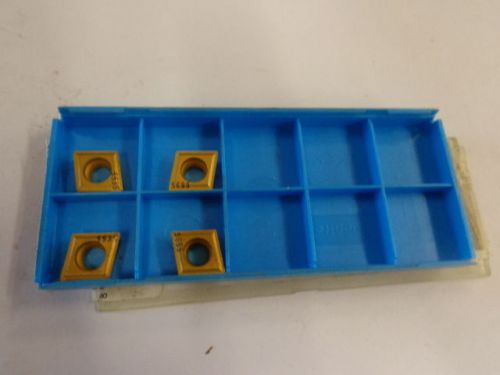

4 VALENITE CARBIDE INSERTS CPMT 32.51 1A VP5535 STK6043

10 VALENITE CARBIDE INSERTS (W) SNEF 120408EL SM318 STK6048

ISCAR 40pcs. GIMY 808 IC635, GROOVING,NEW INSERTS

Kennametal Cutting Tool # DTJNRS 205 Insert TN 54

People who viewed this item also vieved

"HASSAY- SAVAGE" 1/4"III Keyway Broach

"DUMONT" 3/16-C HS Keyway Broach

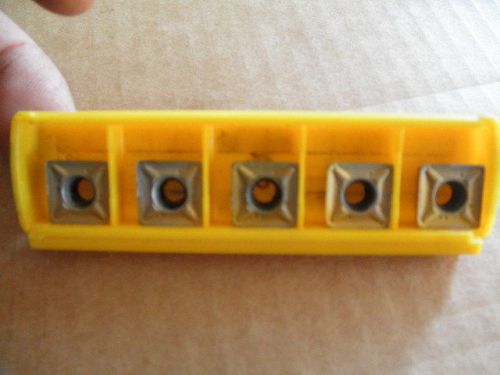

FIVE KENNAMETAL SDCT43PDFR8LD SDCT1204PDFRLD KC705M INSERT a5

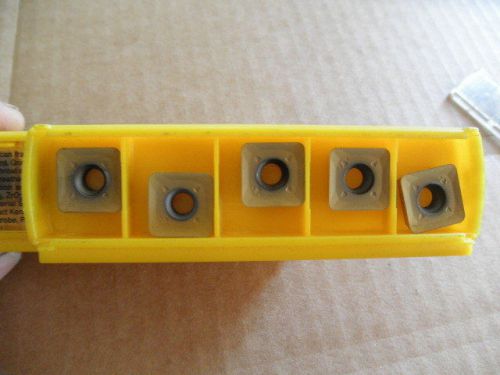

FIVE KENNAMETAL SDCT434ENLD2 SDCT120434ENLD2 KC725M INSERT a8

Data Flute 3/4" Carbide Corner Rounding End Mill 3/4" Shank NEW A2

Machinists 11/30 A BUY NOW USA Ford 1" Camfer Bit Cheap Ship Combine

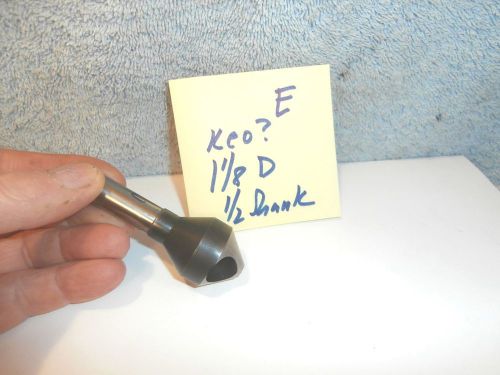

Machinists 11/30 A BUY NOW Centerless Camfer Bit E Cheap Ship Combine

STRIPPIT DIE ROUND 0.073 ID X 1-7/8 OD X 1-3/16 THICK #52829

PUNCH STRIPPIT ROUND WITH FLAT 0.195 X 0.125 X 5-7/16 X 1/2" SHANK #9177

(#4213) Used Machinist .8505 Long Flute Straight Shank Chucking Reamer

(#4428) Used Machinist USA Made 61/64 inch MT Shank Reamer

UMachinists 11/29B BUY NOW SA National Slit Saw Blade 1/16 x3 x1" hole

Machinists 11/29B BUY NUSA Niagra Carbide Circular Mill Cutter Just Resharpened

10pcs 1.5mm Carbide End Mill Endmill Tungsten Steel Blade CNC/PCB Engraving Bit

10pcs 0.2mm Carbide End Mill Endmill Tungsten Steel Blade CNC/PCB Engraving Bit

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies