US $59.00

Directions

Similar products from Instruction Manuals for Metal Cutting

Delieg Microbore VRZ742 Operational Data Manual

Haas HRT Indexer 2005 Operators Manual

5 Magazines CNC Milling / Modern Machine / Quality Lot 63 Gently Used Smoke Free

Haas VF Series Milling Machine Service Manual Jan 1998 *114

Pratt & Whitney Instruction Book for Supermicrometer (Inv.18001)

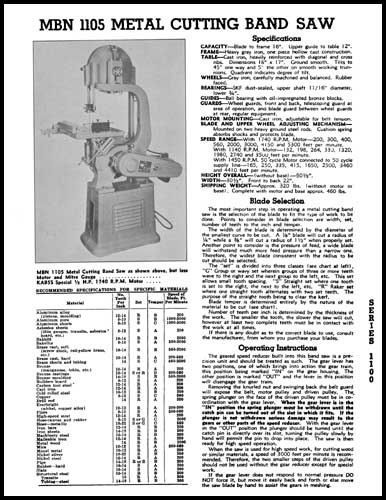

Walker-Turner MBN 1105 Metal Cutting Band Saw Manual

Gallmeyer&Livingston Operat. Instruct Model 25 Thru 65A, INV 6347

STRIPPIT FABRICATOR SUPER 30 - SERVICE MANUAL

1956 INDUSTRIAL BROCHURE & SPECS # 56 SUNDSTRAND DRILLING & CENTERING MACHINE

How To Run A Lathe Care & Operation Vol. 1 South Bend Lathe Works 1945 45th Ed.

SOUTH BEND LATHE 17" TURN-ADO MAINTENANCE MANUAL

Do You Know All of The Cutting Tools Companies in the World?

Metalworking Ballnose Endmills Cutting Data Calculator for Cutting Carbide Tools

Okuma MC-5VA Vert. Machining Center Parts Book: ME15-018-R8 (Inv.9999)

Tru-Trace Application Photos-180 Milling catalog

Cincinnati Milacron 10vc-1000 Manual Package

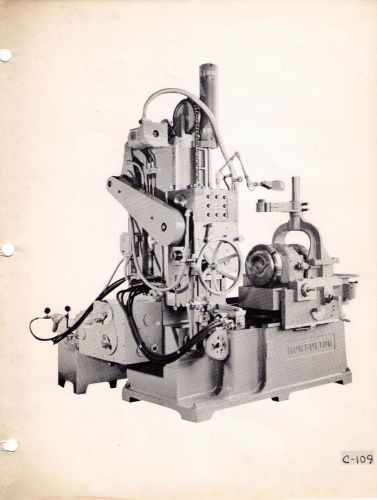

Vintage Rare Bullard Mult-Au-Matic Vertical Turret Lathe Book Original Photos

American Tool Programming Manual ATI/Bendex System 5M CNC Control Model 2010

American Tool Maintenance Manual CNC Control Model 2010

American Tool Operators Manual CNC Control Turning Center Bendix Control

People who viewed this item also vieved

Marks Mechanical Engineer Handbook Textbook-5th Edition-McGraw/Hill-Finger Index

MACHINERY'S HANDBOOK 10th EDITION-The Industrial Press-1941-Vintage-collectable!

Universal Machinist Handbook 1951 Shields Publishing Company St. Louis

KEMPSMITH Universal Dividing Head 10 1/2 & 13 1/4 Owner's & Parts Manual 1079

Machinery's Handbook Toolbox Edition, 23rd Edition, free shipping in USA

DoAll Job Selector Surface Grinding Operators Guide and Wheel Selector 20 pages

Machinerys Handbook 15th edition

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies