US $22,770.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Country/Region of Manufacture | Turkey |

| Model | PS 85 | ||

| Brand | KAAST |

Directions

Similar products from Tools for Fabrication Equipment

PEXTO 8911, ROPER WHITNEY 622LR,CRIMPER BEAD ROLLER; STEEL BENDER; FORMER

PRESS BRAKE DIE TOOLING - 4-WAY DIE WITH SLOT 5.25" SQUARE 47.5" LONG

Rapid- Air Coil Feed Uncoiler R3A124DS 150# CAP 115/230 1PH USED

ASAHI US BAIRD 219 TRANSFER PRESS

J A Richards Multiform Bender/Cutter

#NH5212 NATIONAL 52" x 12 Gauge Hydraulic Shear

HYDRAL FINE BLANKING PRESS (28655)

160 METRIC TON OSTERWALDER FINE BLANKING PRESS(28654)

Kick press foot stamping die arbor punch whitney pexto famco button grommet snap

FAMCO #10 Kick press foot stamping die arbor punch whitney pexto button grommet

Lockformer 20 Ga. Button Lock Machine 1 Phase HVAC

Wing Bender Automatic Form Fixture Sheet metal Brake VIDEO

Wing Bender Form Fixture Automatic Sheet metal Brake Way Cool VIDEO

8' AMADA PROMECAM CNC PRESS BRAKE 80 Ton (28466)

Used Rotex 18-A Turret Punch Press (Manual)

STANLEY U214A UNISHEAR NIBBLER SHEET METAL SHEAR 14 Gauge

Vintage PEXTO Sheet Metal Stove Pipe Crimper Hand Pliers Type Roller Tinsmith

People who viewed this item also vieved

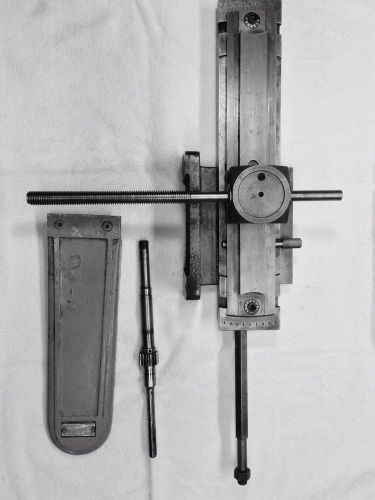

Lathe Tool Post Holder and Tools for Atlas or South Bend

ANTIQUE ? VINTAGE TOOL LATHE POSSIBLE JACOT PIVOT ? BRASS ? WATCH REPAIR IN CASE

clausing lathe taper attachment 7114

EDGE FINDER by MOORE TOOLS BRIDGEPORT CT

1995 SUPERTEC (TAIWAN) STG-450A 6" X 18" ID/OD UNIVERSAL CYLINDRICAL GRINDER

10" X 31" CINCINNATI-MILACRON R-77 UNIVERSAL OD CYLINDRICAL GRINDER

UNISON "DEDTRU" MODEL: 288-0000 CENTERLESS GRINDER w/POPE Spdl, HARIG BASE

MASTER CASTING MODELS-WHITE METAL- FASHION, COSTUME,RELIGIOUS, RECOGNITION MORE

GRS STAINLESS HANDPIECE JEWELRY HAND ENGRAVING TOOLS 2YWARRANTY NIB 004-940-ATSS

GRS STAINLESS HANDPIECE JEWELRY HAND ENGRAVING TOOLS 2YWARRANTY NIB 004-921-ATSS

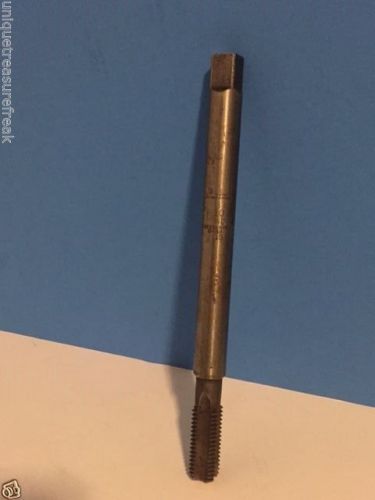

VINTAGE PRATT WHITNEY DRILL BIT B-10 TEN 10 INCH NC 15 DRILLING TOOL METAL WOOD

INDEXABLE CARBIDE INSERT DRILL 1 1/4" shank x 1 3/8" dia lathe mill tool holder

(2) Gundrill 1-Beyer 40" Travel & 1-Drillmation Gun Drill 32" Dual Spindles

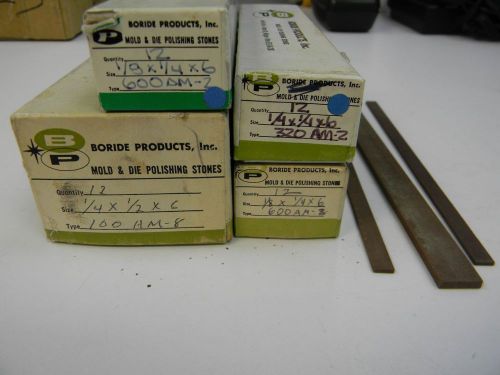

BORIDE & GESSWEIN MOLD & DIE POLISHING STONES (LOT OF 4 BOXES)

Sunnen Horizontal Hone, Model MBB 1600 MS NO RESERVE!

(Qty. 17) Sunnen K8-J95 Honing Stones - NEW

EDM DIELECTRIC OIL CHARMILLE MITSUBISHI SODICK

POCO EDM-3 GRAPHITE GROUND BLANK 4.000 X .750 X 6.000

2005 CHARMILLES FORM 20 ZNC RAM TYPE EDM, 64 AMP POWER, TOUCH CONTROL

H&G Die Head Thread Chaser Style D Size 9/16

Landis Landmatic 5F8422-1 Die Head Thread Chaser

11" Blade Dia 1.5hp HP Baileigh CS-275EU COLD SAW, 110v, manual feed

12.5" Blade Dia 2.5hp HP Baileigh CS-315EU COLD SAW, 220v 1-phase, european styl

14" Blade Dia 3hp HP Baileigh CS-350EU COLD SAW, 220v 1-phase, variable speed, i

NIB! Melcut Subland Step Drill/Reamer Bit 7/16"x 7" oal

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies