US $370

| Condition | Used

:

An item that has been used previously. The item may have some signs of cosmetic wear, but is fully operational and functions as intended. This item may be a floor model or store return that has been used. See the seller’s listing for full details and description of any imperfections.

|

| Seller Notes | “BEAUTIFUL VINTAGE CONDITION! CLEAN & SHINY! COPPER PLATED!” |

Directions

Similar products from Letterpresses & Printing Blocks

Vintage Letterpress Printing Block - CMS Community State Bank

Vintage Letterpress Wood Printer's Block Punctuation Set mixed fonts 50 blocks

Vintage / Antique Letterpress Wood Printer's Type "!", 3 blocks, 2" tall,

Vintage / Antique Letterpress Wood Printer's Type "!", 2 blocks, 3" tall,

Palmolive Super Suds For Washing Clothes Copper or Brass on Wood Block Stamper

Vtg Letterpress Wood Copper Printers Block - CHICKENS ROOSTERS /Religious

Antique letterpress printers wood type AMPERSAND &

1920's or 30's Off-Set Printing Printers Photo Block Copper Plate/Wooden Block

Letterpress printers cut CAT in WATER BUCKET! Bowtie CUTE! VERY DETAILED ORNATE!

letterpress printers wood type Full ALPHABET/ NUMBERS/ Punctuation 341 pieces

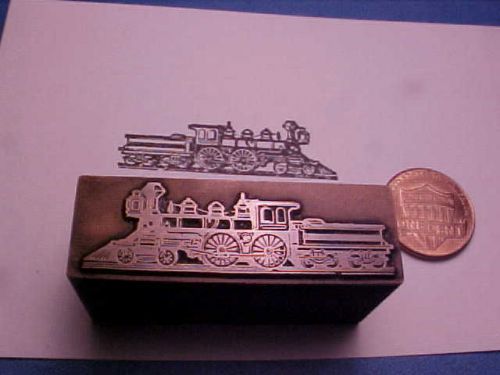

Letterpress printers 1800s STEAM LOCOMOTIVE! Train,Wood,Coal Tender NICE DETAIL!

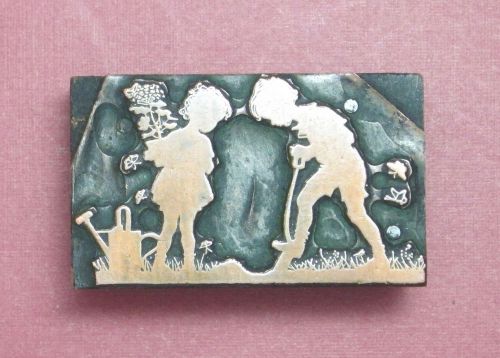

Young Boy and Girl Planting Flower Plant Image Letterpress Printing Print Block

INDIAN WOODEN HAND CARVED TEXTILE PRINTING ON FABRIC BLOCK STAMP LINE CARVING

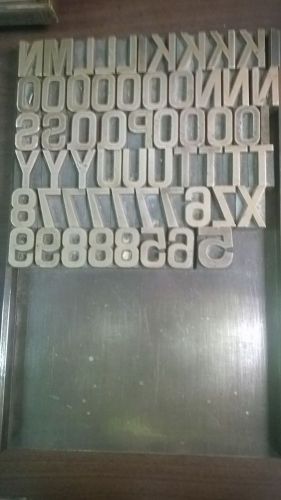

Vintage large letterpress solid brass type

Antique letterpress printers woodtype 12pc.symbols,dollars period coma $ , . old

INDIAN WOODEN HAND CARVED TEXTILE PRINTING FABRIC BLOCK STAMP UNIQUE ART

Vintage Rubber Stamp Printing Blocks-Letters, Numbers, Cowboys, More 81 Pieces

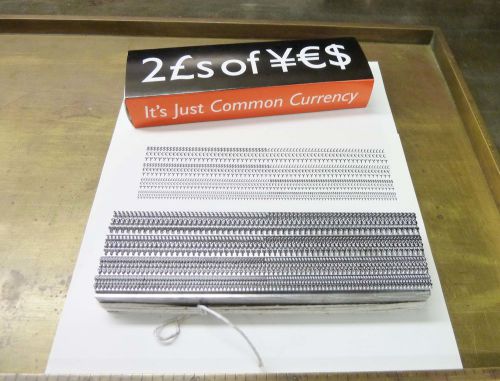

Letterpress Type - Currency Symbols

Vtg Letterpress Metal Typeset Letterpress Letters Bulk Asst 5lb Dom Diagonal 18p

INDIAN WOODEN HAND CARVED TEXTILE FABRIC PRINTER BLOCK STAMP ETHNIC DESIGN PRINT

People who viewed this item also vieved

HP Indigo Impression Films for 3000,5000 Series

Risograph GR black Ink Tube G1

1 set=4pcs/set- 30pin 3pcs and 50pin1pc - Mimaki JV33-160 Long Data Cable 3050mm

H1 ?6 Tube Fitting for All wide format inkjet printers

Adidas Classic Vector Logos Vinyl Cutter Plotter Graphic Decal EPS READY

Adidas Vector Logos Vinyl Cutter Graphic Decals Clipart Sign Wall Sticker Art

MLB Vector Logos Vinyl Cutter Graphic Decals Clipart Sign Wall Sticker Art

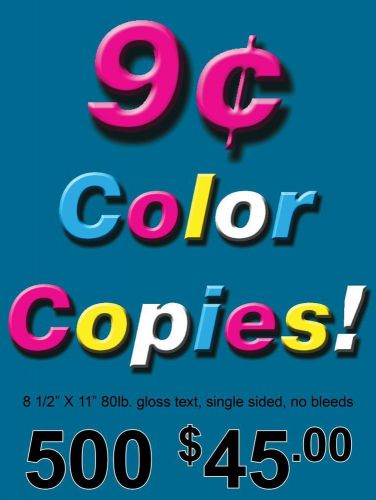

500 Single Sided Full Color Glossy Copies 8.5 x 11

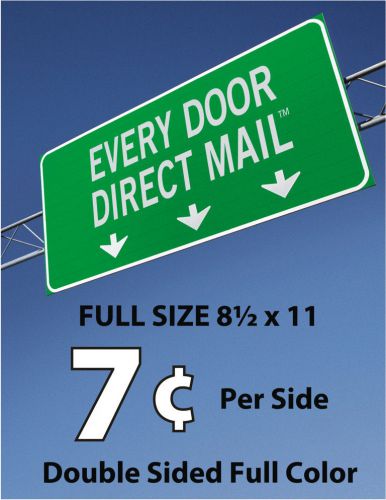

600 Full Size Every Door Direct Mail Double-Sided Full Color

REA ELEKTRONIK SG1/16B + SKSP 16/35C REA JET SG PRINTER

X-Rite DTP32HS Auto Scan High Speed Densitometer Spectrophot Xrite

X-rite 331 Transmission Densitometer Battery Operated B/W Xrite Excellent Cond.

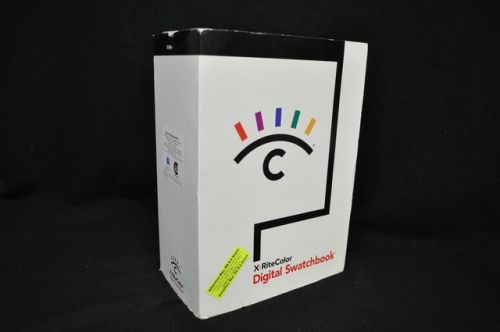

X-Rite DTP22 Digital Swatchbook Color Densitometer MAC Xrite Spectrophotometer

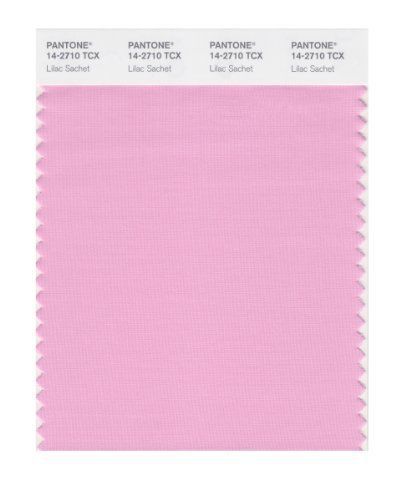

PANTONE SMART 14-2710X Color Swatch Card, Lilac Sachet

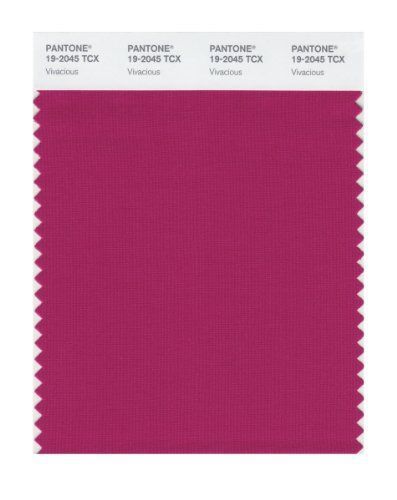

Pantone 19-2045 TCX Smart Color Swatch Card, Vivacious

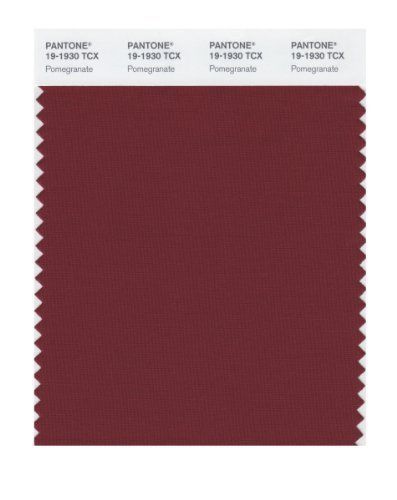

Pantone 19-1930 TCX Smart Color Swatch Card, Pomegranate

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies