US $30,000.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | GENIUS |

| Country/Region of Manufacture | India | ||

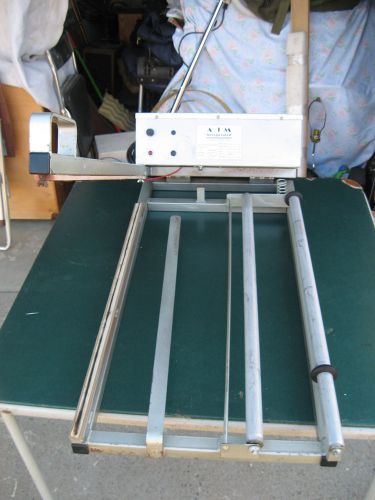

| Model | GE-22 (station) |

Directions

Similar products from Sealing Machines & Bag Closers

Interpack Intertape USA 20 SB/3-BO Carton Sealer Taping Machine

8166 TEW TISF-450 BAG SEALER 18" ON STAND

MIDWEST PACIFIC MP-12 IMPULSE HEAT SEALER 12 " INCH BAG TUBING

TEW TISH-300 110V Electric Heat Impulse Sealer 12" Blue -WORKS-

American International Electric impulse sealer AIE-400P

BRAND NEW TORRINGTON FAFNIR BALL BEARING INSERT ER24

Vertrod Thermal Impulse Heat Sealer

GENERAL ELECTRIC AUXILLARY CONTACT BEL02.NEW IN PACKAGE. VB9

SLOAN V551-A VACUUM BREAKER REPAIR KIT FOR V-500-A & V-500-AA.VB9

CSM-5000+ Premium Carton Box Case Sealer Carton Tape Sealing Machine **CSA**

Kmasters CSM-5020S Carton Box Case Sealer Tape Sealing Machine Stainless Steel

AJM Inc, 26" Commercial Sealer Machine Shrink Wrap Film Sealing Model 26

Uline Plastic Strapping Sealer H-57-1/2 NEW IN BOX

Signode 1 1/4" Side Action Banding Sealer

Lot of 4 - SUPER VAC VACUUM PACKAGING/SEALER PLATES, MODEL GK165 (G3)

ULINE H-190 12" IMPULSE SEALER FOR POLY BAG 120V

FIEBIG SUPER VAC VACUUM PACKAGING/SEALER TEMP GAUGE MODEL GK165 (G3)

SUPER VAC VACUUM PACKAGING/SEALER MOTOR MODEL GK165 (G3)

METCO 11E FLAM SPRAY GUN. plus extra parts gun

People who viewed this item also vieved

Used- Quadrel Versaline 2000 Double Head Front Back and Wrap Pressure Sensitive

Used- Pack West Model Auto 120 Right-To-Left Automatic Inline Spindle Capper. si

Used- Autopak Model APCP Conveyor. Set up in a U-shaped configuration. Adjustabl

Used- Vanguard Model PCX-III Capsule Polishing and Sorting Machine. Capable of p

Used- Mettler Toledo Safeline Model 25 Tablet Metal Detector. Has a 3" long by 1

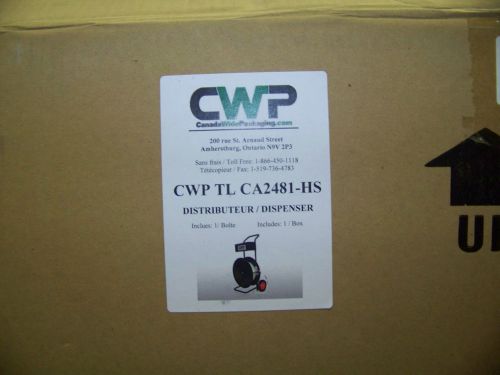

Canada Wide Packaging Strapping Dispenser # CWP TL CA2481-HS New

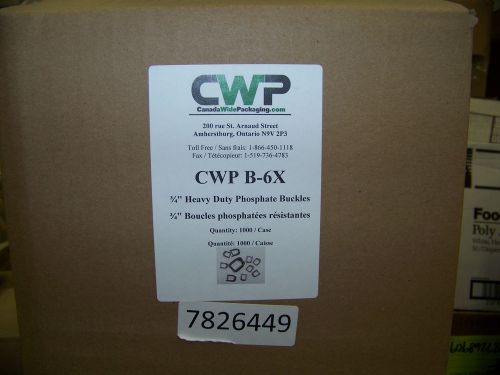

Canada Wide Packaging 3/4" Heavy Duty Phosphate Buckles Poly 1000 ea. CWP B-6X

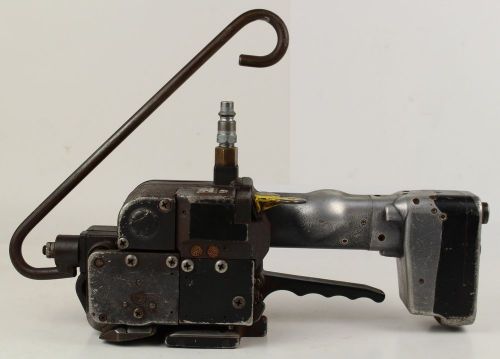

Fromm 49.0363 Pneumatic Plastic Strapping Tool 5/8" P356 USG

Signode Manual Seal-Feed Combination Steel Strapping Tool 1/2" AM-12 USG

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies