US $18.99

Directions

Similar products from Glueing Tools & Cements

Gluegun-Heavy Duty Adhesive Technologies Super Glue HD2600 026438542158

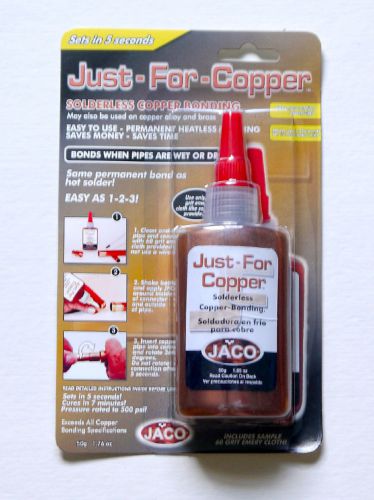

JACO Just-For Copper Solderless Copper Bonding JFC050 1.76 oz

WEICON Flex + bond Adhesive Case of 12 (3 Grey, 3 Black, 3 White, 3 Transparent)

WEICON Repair Stick Steel 57g Industrial Putty Pack of 3

WEICON Repair Stick Copper 57g Putty Fix Plumbing Leaks Pack of 3

WEICON Repair Stick Stainless Steel 57g Industrial Putty Pack of 3

Lot Of 2 Super Glue New All Purpose Adhesive

Loctite 2400 NA Blue Medium Threadlocker 250 ml 1526122 Large bottle new

LOCTITE Hysol 608 Fast Setting 5-minute Crystal Clear General Purpose Epoxy

LOCTITE Hysol E-05CL Fast Setting Crystal Clear Epoxy Gel (Thixotropic)

3M Scotch-Weld Adhesive Gun Kit for 1:1 50mL and 2:1 37mL cartridges

Always Fresh 500 Super Fresh Glues Art Craft Cars Plains Trains Model Construct

Wurth USA Multi Purpose Sprayer # 891110 UBS-Pistole

NEW 3M HI-STRENGTH MODEL 90 HIGH STRENGTH SPRAY ADHESIVE HIGH TEMPERATURE 17.6OZ

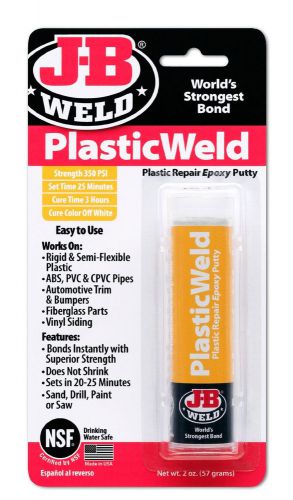

New J-B Weld 8237 Kwik Plastic - 2 oz.

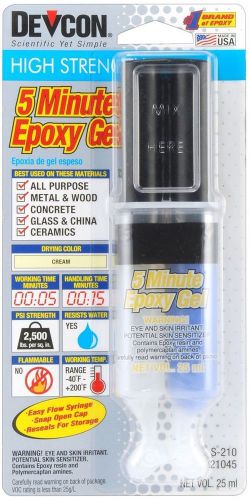

New Devcon S210 5-Minute Epoxy Glue Gel 1-Ounce Tube

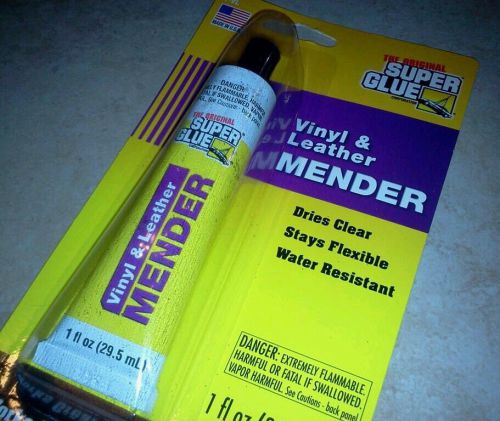

SUPER GLUE Vinyl Leather Mender - Repair Leather Handbags, Coats, Boots, Etc

People who viewed this item also vieved

100ML Dispensing Syringes Barrels , Tips & Caps Adhesive Glue Ink Luer Lock

SIMPSON EDT22S EPOXY DISPENSING TOOL (CP1001398)

NEW StrongArm 6306 Lincoln Navigator Hood Lift Support Pack of 1

NEW StrongArm 4584 Ford Explorer Liftgate Lift Support Pack of 1

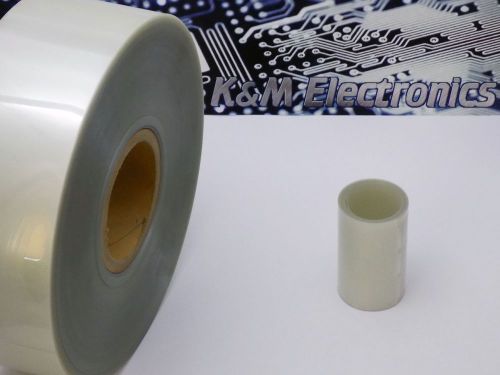

2m Hostaphan - 78 mm x 0.3 mm BoPET Polyester Polyethylene PET Insulation Foil

NEW Brand New! Scotch Magic Tape Value Pack (810P10K) 10 rolls

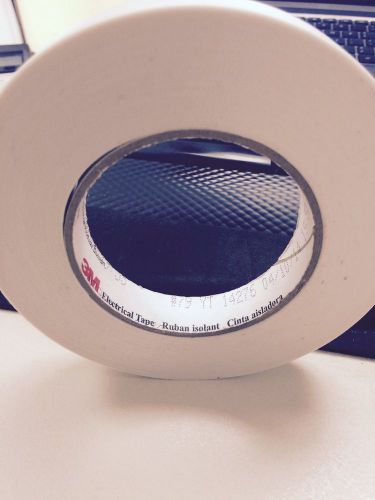

3M 79, 3/4 in x 60 yd Cloth Tape,3/4 x 60 yd,7 mil,White

3M 06349 Trim Masking Tape 2" x 10.94 yd

3M 1.5" x 5 Yards Scotch White Duct Tape

LOCTITE 5510 ADHESIVE SEALANT GREY

NPC Solar Seal #900 Adhesive Sealant Clear calk New

(25) Hilti FS-ONE #311387 HIGH PERFORMANCE INTUMESCENT FIRESTOP SEALANT***

Loctite 242 Medium Strength Threadlocker Blue-0.34 FL. Oz. P/N 24221 Brand NEW

Magic Tub & Floor Sealer Trim /White/Blanco

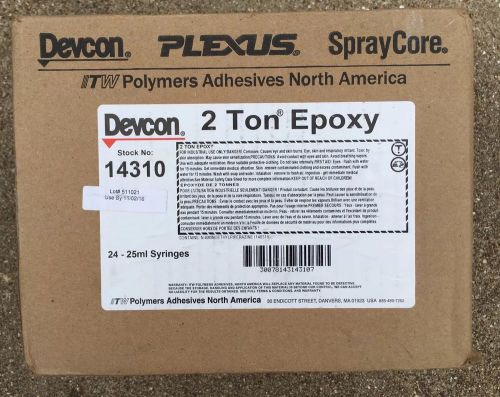

DEVCON 2 TON CLEAR EPOXY adhesive 24 per CASE #14310 25ml syringes

Permatex 82150; Gasket Sealer; Ultra Black;; 3.35 Ounce; NEW REDESIGNED

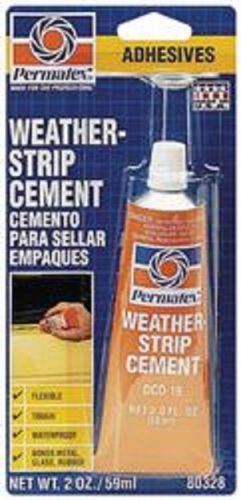

Permatex 80328;Adhesive; Use To Bond That Adheres Rubber To Glass And Metal;2oz

Loctite 1365868 Instant Mix Epoxy, 0.47 Oz , 25% off

Lot Of (1) Powers Fasteners Adhesive Anchoring System, AC100+, 12 Ounce

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies