US $220

Directions

Similar products from Cordage

Vintage large Hook to Hook Turnbuckles Heavy duty Turnbuckle. 14" Body

Swivel Hoisting Eye Hook 1/2" 2500 Lb Center Pull,Lifting,Rigging

CROSBY-LAUGLIN SWIVELER 3 TONS Headache Ball Overhaul Ball Hook &Swivel Eye 35LB

Lot of 10 New Crosby A330-1-4 Clevis Grab Hooks Hook For Chain 3,500 Load Limit

Loos Cableware C2 Felco Snub Cable Cutter for 2.5mm Wire Rope

Forney 61267 Square Eye Snap Hook 5/8-Inch-by-2-3/4-Inch Overall Length

Ideal 31-841 Pro-Pull Rope 1/4" x 1000

Ideal 31-844 Pro-Pull Rope 3/8" x 250

Lot of screw pins, thimble standard duty, wire rope clip

Loos Stainless Steel 302/304 Wire Rope 7x7 Strand Core 5/32" Bare OD 50 Lengt

Wire Rope Sleeve Single Groove O-18 Hand Swagger Tool

Heavy Duty Soft Crane Round Rigging Sling 20' x 10 Ton Orange

Loos Galvanized Steel Wire Rope Vinyl Coated 7x7 Strand Core Clear 3/32" Bar

The Perfect Bungee 16-Inch Utility Suspender Tan

Loos Cableware ST2-1.5 Copper Crimping Stop Sleeve Set for 3/64" Diameter Wire R

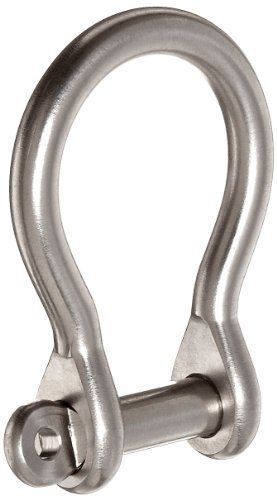

RONSTAN RF637 Grade Stainless Steel 316 Bow Shackle 3/8" Pin Diameter 2" Lengt

Indusco 16100001 Drop Forged Alloy Steel Ratchet Type Load Binder 2200 lbs Work

Campbell 1/4" x 250 Galvanized Cable 7000827 Aircraft Cable

Loos Cableware SL1-8 Aluminum Duplex Oval Crimping Sleeve Set for 1/4" Diameter

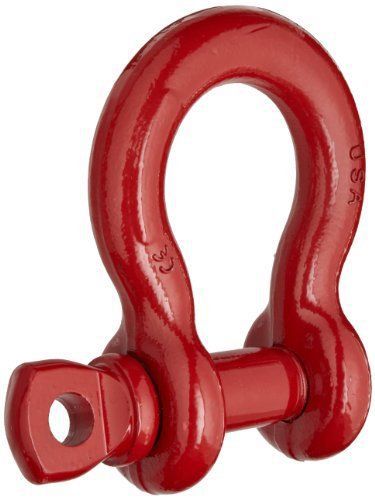

Crosby 1018543 Carbon Steel S-209 Screw Pin Anchor Shackle Self-Colored 8-1/2

People who viewed this item also vieved

HARRINGTON LB MANUAL CHAIN LEVER HOIST, 3/4 TON, LB008 5FT LIFT

Columbus McKinnion 3 ton Electric Chain Hoist

CM 3 TON X 20' RATCHET LEVER CHAIN HOIST COME A LONG

New 880LB ELECTRIC MOTOR OVERHEAD GARAGE HOIST CRANE LIFT w/Emergency Stop

Material Handling Crane Lift Hook Block Single 12" Sheave

Crosby Laughlin Material Handling Crane Lift Hook Block MC216 Single 33" Sheave

NULINE Horizontal Plate Clamp 2 Ton QP-Am |KR4|

Aero-Motive Ergomation Balancer 18-25 lbs Ratchet/Free EB2500R Tool Material

DBI/SALA Salalift II Winch 8012001 W/ 1/4" X 60ft Cable & Winch bag L74006

Dayton 4Z327 Electric Winch Wire Cable 2700-4000lbs

Superwinch X3 Electric Winch, 4,000 lb Capacity, 24VDC, 50' Wire Rope, #1314

DP Planetary Recovery Winch, 3000 Pounds, Model 3CPO part number 52005 Good used

Military Winch 35,000 lb Hydraulic Planetary 2 Speed Used Tested

New HWD-600 Work Winch 600lb Max Line Pull HWD600

NEW PITTSBURGH P-189 P189 1,000 LBS WINCH 3/16" X 25' CABLE AND HOOK

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies