US $369.00

| Condition | For parts or not working

:

An item that does not function as intended and is not fully operational. This includes items that are defective in ways that render them difficult to use, items that require service or repair, or items missing essential components. See the seller’s listing for full details.

|

| Seller Notes | “The warning light comes on when switched to plasma cutting or stick mode, I have never used or tested the TIG mode but the light is not coming on if its on this setting when turned on. I had a problem before with the warning light coming on but it went away on its own and worked fine for several months. The light may go away again on its own or may have something loose inside or may need to be serviced. Selling AS IS with no returns.” |

Directions

Similar products from Electric Welder Machines

USA POLISHED ALUMINUM LINCOLN WELDER SA200 SA-200 SA-250 NOSE CONE EXCITER COVER

LINCOLN Outback 145 Engine Driven Welder / Generator K2707-2

New Pro ARC ROD WELDER 200 AMP 110V/220V DUAL voltage MMA WELDING TOOLS

Lincoln Precision TIG 375 TIG and Stick Welder

NEW! MILLER SPOOLMATE 3035 MIG GUN, 25' P/N 195016

Article Plans How To Make Really Good Spot Welder Spot Welding Metal Weld Metals

Miller cp302 mig welder w/ XR wire feeder push pull welding set up VERY NICE!

NEW! SMITH STAGE 2 OXYGEN REGULATOR P/N 35-125-540

TAYLOR WINFIELD 200 KVA SEAM WELDER W/ LATE ENTRON EM 1000 CONTROL (OC432)

LINCOLN ELECTRIC AC 225-5 Stick Welder

TIG & Arc AC/DC Welder, Plasma Cutter & Pulse 200P FOOT PEDAL INC Colossal Tech

TUCKER GmbH WELDING POWER UNIT TYPE 0804 (5 OUTPUT)

Lincoln Electric Power MIG 140C MIG Welder Package K2471-2

Western Victor Smith Welder Oxygen Acetylene Cutting Torch & Regulator Parts Lot

Lincoln Electric 230-Volt MIG Flux-Cored Wire Feed Welder

Airco 225 AMP AC Transformer, stock number 1353-0207

HUGHES HRW-250B HRW250B 250 WATT-SECOND WELDING POWER SUPPLY (#836)

MILLER WELDER CONTROL BOX FOR ROBOT W/ FIBER OPTIC COMPUTER INTERFACE - WELDING

AHP AlphaTIG 200X 200-Amp IGBT Pulse AC DC Tig/Stick Welder 110V & 200V

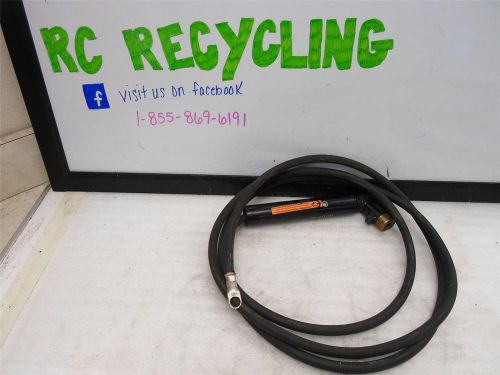

HOBART M-400B ARC STICK WELDER CABLE AND WELDING GUN 600V WELDING CABLE

People who viewed this item also vieved

Fisher Scientific Oxygen Gas Regulator 4000psi

VINTAGE HARRIS OXYGEN GAS REGULATOR MODEL 77-150 650L LOW FLOW

VINTAGE MARQUETTE OXYGEN REGULATOR MODEL 25-110, 1284

275+ Plasma & Router CNC Models Hangers Clocks Frames EPS DXF $97Val on CD-Rom

Miller 231411 (5) & 231410 (2) Pro-Hobby Lens Cover Package

500AMP TWECO STYLE ELECTRODE HOLDER A-38 M500

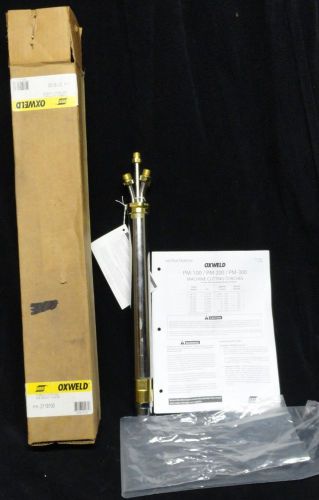

OXWELD Machine Cutting Torch, PM-100-01 13-9/16" P/N: 2118100 *NEW IN THE BOX*

Hypertherm Powermax 45 Plasma Including Machine Torch

LOT OF KOHLER PARTS AIR CLEANER, THROTTLE LINKAGE BUSHINGS, SEALS, VALVE COVER

ESAB Plasma Table, reconditioned in 2012

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies