US $67.90

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Model | MA860H |

| Output Current | 2.6 - 7.2A | ||

| Country/Region of Manufacture | China | ||

| Subdivision | Max.1/256 | ||

| Application | DIY Hobby CNC Mill Lathe Router | ||

| Matched Motor | Nema 23, Nema 24, Nema 34 | ||

| Dirving Voltage | 36 - 110VDC/24-80VAC |

Directions

Similar products from Stepper Motor Driver Boards & Modules

Superior Electric SLO-SYN 2000 Motor Drive SS2000D6 115Vac 7Amps 50/60Hz

Cnc Machine Controller Servo Step Motor Driver DC Power Supply 38- 48V 10A 500W

Cnc Machine 8A 2 phase micro step Bi-PoLar Step motor drive stepper Driver

Cnc Machine Controller 5.8A 3 phase micro stepper drive step Motor driver

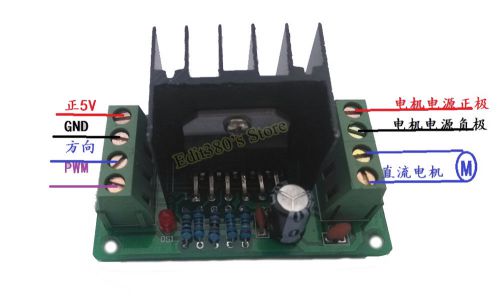

LMD18200T 75W H-Bridge DC Motor Driver Module Board For Smart car Arduino Test

YASKAWA DR1-08ACY9 (SERVO PACK)

3D Printer Kit RAMPS 1.4 Mega 2560 R3 12864 LCD Controller 5x DRV8825 Driver

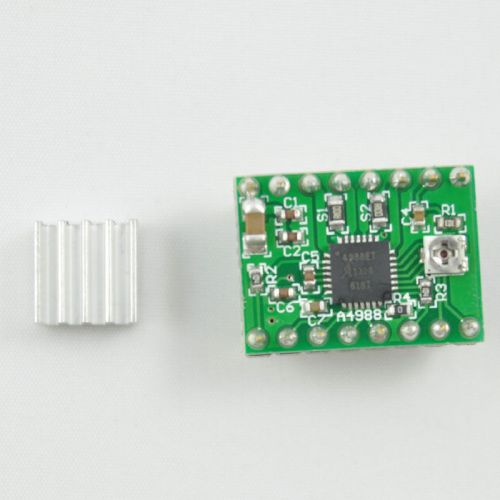

Reprap Stepper Driver A4988 Stepper Driver with Heatsink for 3D Printer

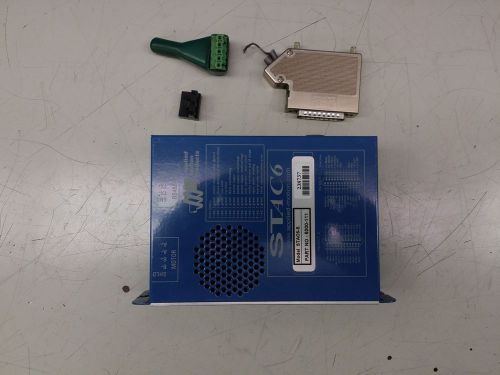

Applied Montion Products STAC6-S-110 Stepper Motor Controller

INTEGRATED SOLUTIONS 046977G1 GCA STEPPER MOTOR Y-STAGE 8"

STEPPING MOTOR HIGH TORQUE 1.324 N./m KH56QM2

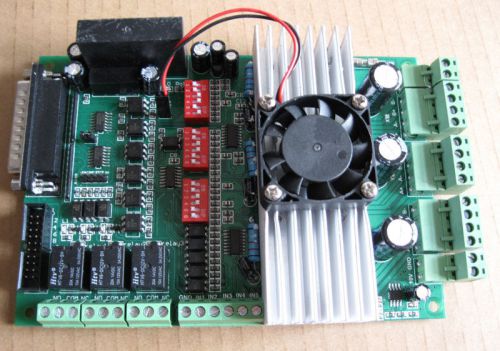

New 3 Axis CNC 4.5A Router TB6600 Stepper Motor Driver Board Controller

4-Axis USB Stepper Motor Controller/Driver with Limits

PACIFIC SCIENTIFIC K33HLHJ-LNK-NS AC STEPPING MOTOR, 65 VDC, 1.8* STEP

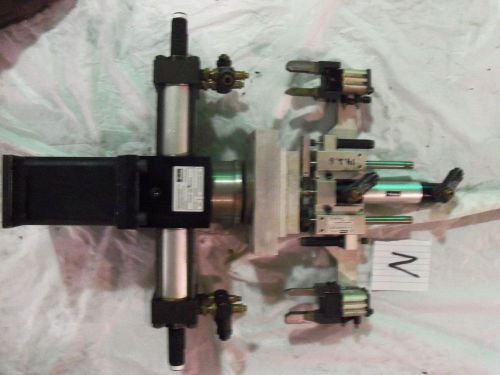

Parker Pneumatic Cylinder Assembly

Parker Pneumatic Parts Transfer

New 3D Printer Kit RAMPS 1.4 Mega 2560 R3 2004 LCD Controller 5x DRV8825 Driver

Robbins Myers IBM Motor Thermally Protected 1.1a 1750 RPM 1/35 HP IBM PN 2305467

Stepper Motor Nema 17 Bipolar 40mm 64oz.in(45Ncm) 2A 4 Lead 3D Printer Hobby CNC

People who viewed this item also vieved

Oriental Motor VEXTA Low-Speed Synchronous Motor 100/115VAC SMK5160A-AA NNB

LOT OF 2 (TWO) GATES B79 HI-POWER II V-BELT **NEW**

Asco 154132 Auxiliary End Shield for Contact Assembly

ALLEN-BRADLEY 700DC-N200Z24 DC RELAY SERIES C

NEW IN BOX Pepperl + Fuchs KFA6-SR2-EX2.W KFA6SR2EX2.W ALL NEW 103373

NEW IN BOX Pepperl + Fuchs KFD2-SCD2-EX1.LK ALL NEW

Allen-Bradley 150-A16NA SMC-2 Motor Controller

1PC NEW IN BOX Mitsubishi Servo Drives HF-SP152B 1.5KW

1PC NEW IN BOX Mitsubishi Servo Drives HF-SP201

1PC NEW IN BOX Mitsubishi Servo Drives HF-SP201B

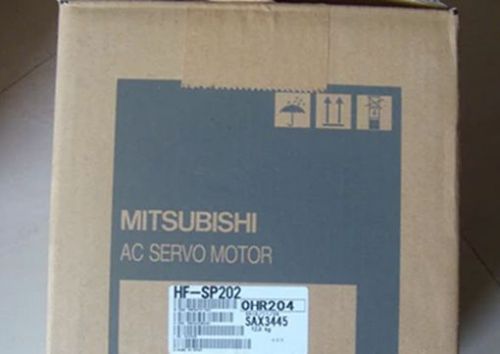

1PC NEW IN BOX Mitsubishi Servo Drives HF-SP202

1PC NEW IN BOX Mitsubishi Servo Drives HF-SP202B

1PC NEW IN BOX Mitsubishi Servo Drives HF-SP352

1PC NEW IN BOX Mitsubishi Servo Drives HF-SP352B

ELECTRO CRAFT E-552-M MOTOMATIC SPEED CONTROLLER (B)

DODGE 025623 DBS MOTOR BRAKE 208-230/460 VAC W41

GRAHAM CYCLETROL 176B6000 *NEW IN BOX*

Raffel # FSC6-120 Speed Control (NEW)

Dengensha AF-VNW-C16-6-DRD Vibratory Bowl Feeder 115 VAC Top Shaker & Bowl (TSC)

Nederman 03230-00 03250-00 Fume Extractor Fan 0323000 0325000 14510222 (TSC)

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies