US $1100

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | Unbranded/Generic |

| Model | High Precision Manual Printing Machine | ||

| MPN | Does Not Apply | ||

| UPC | 987792913643 |

Directions

Similar products from Stencil Printing Tools & Accessories

US 50pcs 19"x16" Adjustable T-Shirt Cloth Fast Folder Folding Board Organizer

Riley Hopkins Jr 4 Color 2 Station Screen Printing Press, Micro Registration

Emulsion Scoop Coater 16 Inches

TWO STRETCH DEVICES tension gauge NEWMAN ST METER 1B used in screenprinting

4 Color 1 Station Silk Screen Printing Press Machine Screening Pressing

Hat Press, Sublimation or Heat Transfer, Swing-Away Design

Aluminum Screen Printing Screens Size 9 x 14 Inch Pre-stretched Silk Screen F...

RileyCure Conveyor Dryer / Oven - Screen Printing

Ryo Flash Dryer with Stand and Casters 16x16in, 1600-Watt, 15 amp, Screen Printi

X-Vactor Vacuum Light Table / Exposure Unit

Mug Printing Machine New 11oz Mug Heat Press Machine Sublimation Mug Printer

120T Silk Screen Printing Aluminium Frame Size (11x14") High Quality Mesh

Riley Hopkins flash dryer by Ryonet 18"x24"

Durable Lightweight Hard Rubber Brayer with Metal Handle, 6 in, Black

Exposure Unit Uv Screen Printing 19x18 Press A Print Precision Digital Timer

Douthitt Heavy Duty Direct Method Screen Vacuum Frame (42" x 52")

(TS2) 3 Partial Cans, #1 Network, Ink Anti-Skin No Wash-UP Spray 950S, SW-950

50 -10"x30" "H" Wire Step Stakes.

People who viewed this item also vieved

Vintage NEW HERMES Engravograph with Motor

125 GOLD NEW ALUMINUM ENGRAVING MACHINE PLAQUE & TROPHY PLATES 1X3" TROPHIES

Diamond Drag Engraving Bit 120 degree USA Made 11/64 X 8 for Engraving Machines

Rowmark Name Badge or Name Tag Frames / Holders (Qty: 8)

STAHLS 8" TACKLETWILL PRO & VARSITY NUMBERS

Anajet mPower MP5i Direct To Garment Printer

Videojet Hi-Res Oasis Centralized Ink Management System 250W 27070 NNB

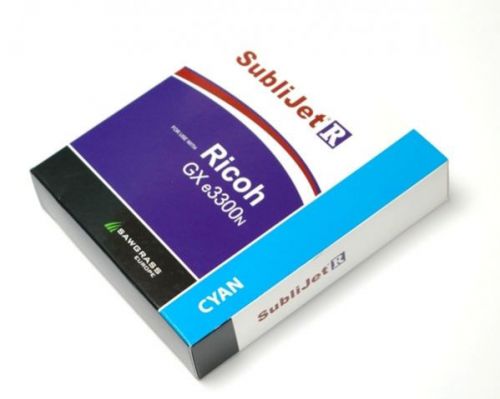

SAWGRASS SUBLIJET - R SUBLIMATION INK CYAN (C) FOR RICOH GX e3300N e7700N

Crown Roll Leaf Inc. Hot Stamp Foil #BW88-990E - 200ft. x 18"

Crown Roll Leaf Inc. Blue Hot Stamp Foil #BW88-510E - 400ft. x 10"

Crown Roll Leaf Inc. Blue Hot Stamp Foil - 1000ft. x 16"

API Group MoonGlow Yellow Hot Stamp Foil #PMV5801 - 100ft. x 6"

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies