US $639.90

Directions

Similar products from Other Lab Utensils & Expendables

40cm PTFE stir paddle Teflon stirrer stainless steel core

5pc Non-Magnetic Precision Stainless Steel Tweezers

Quartz Female Nail 14mm Banger USA seller ~new~ Free Shipping

UltraCruz Lab Marker, Fine tip, Blue 10/pk (sc-360973)

VOLLRATH Stainless Steel Beaker w/ Handle SS 4 Quart #79540 Darkroom Laboratory

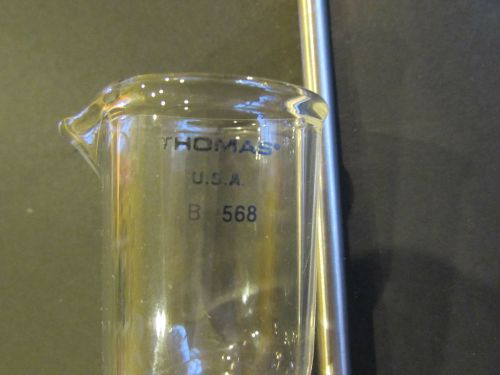

THOMAS SCIENTIFIC TISSUE GRINDER SIZEB 30mL SMOOTH PESTLE

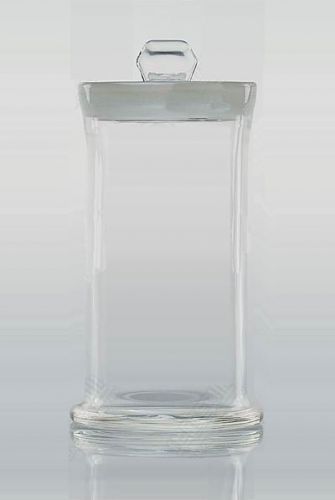

Lab glass Apothecary Jar, Specimen Bottles 210x60mm new

PIPETAID 115V AC VACUUM PRESSURE

Corning Falcon 6-well tissue culture plates. Ref number 353224. Case of 36

90 triangular graduated clear beakers polypropylene 32oz / 1000ml

Chemical Indicator Strips, Steam Sterilization, dental, tattoo, autoclave

Plastic Spectrophotometer Cuvettes, 100 pk

Phinex Diagnostic Ph Test Strips, 80ct -2 pack (160 strips) Results in 15 Sec...

HealthyWiser Ph Test Strips, 100ct Per Pack Accurate Results in 15 Seconds - ...

14MM 18MM Ti Titanium GR2 Nail Carb Cap NEW

10MM Ti Titanium GR2 Nail Carb Cap NEW

Tapered Cork Stoppers,Size 2 Pack of 18, 1/2" X 3/4" New In Pack

NEW AGILENT 5065-9940 PRE-PACKED TUBES FOR RNA-ASSAYS

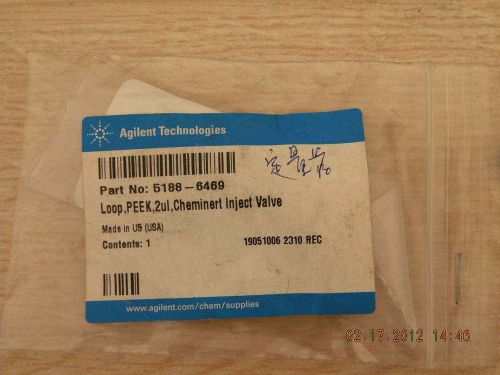

NEW AGILENT 5188-6469 LOOP PEEK 2uL CHEMINERL INJECT VALVE NIP

People who viewed this item also vieved

BTX Electroporation Cuvettes Plus Model. 640 4mm Gap Sterile Single Use 10 pk

BTX Electroporation Cuvettes Plus Model. 610 1mm Gap Sterile Single Use 1 ea

4 Stainless Steel Filter Enclosures & 11 MSA Type H 95302 Ultra Filter Cartridge

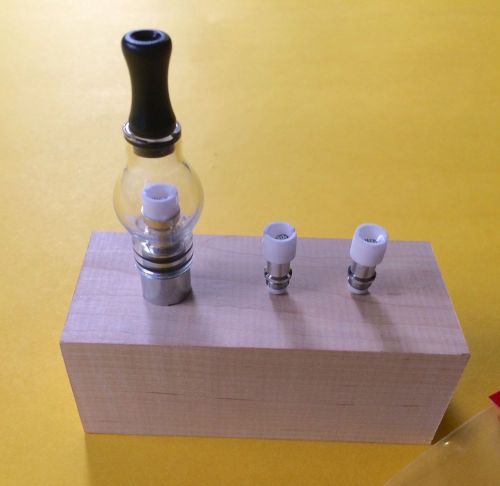

Glass Globe Wax Atomizer Tank Set + 2 Extra Coils + Bonus Kit - Fits 510 / EGO

HPS NW 50 Centring Vacuum Coupler/Clamp

ChemGlass Chem Jack CG-3053 - Used Excellent Condition

Titanium Dioxide / Fine Powder / 0.5 Pounds / 99.99% Pure / SHIPS FAST FROM USA

Titanium Dioxide / Fine Powder / 10 Ounces / 99.99% Pure / SHIPS FAST FROM USA

14mm Male to 14mm Frosted Glass Hookah Adapter With Handle 14 mm Heavy Hitter

Vintage 20 ML Glass Syringe ~ #125 ~ Never Used

Used LaMotte Chemical soil test kit, Model STH-5, (code 5007), No Reserve

Lab Paq Microscope: With Some Slides

Elastic Loop Tool Tails™ - 15lbs (6EA)

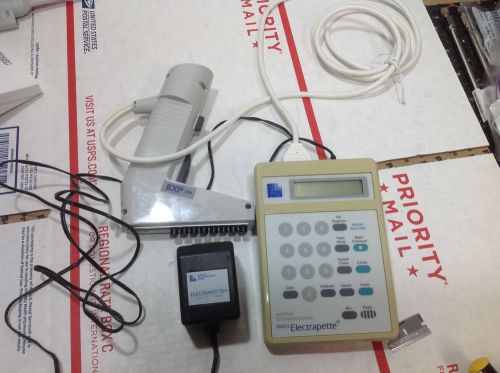

Matrix Multi-Electrapette 8 Dispenser Controller Pipette EXP 1250 ul

CAPP multichannel pipette 8 channel Adjustable 0.5-10uL pipettor #1

1000 Test Tube 12 x 75 mm Polystyrene 5mL Oriented w/Red Ribbed Plug-Tite Caps

1.7 ml Microtube, Clear, Graduated w/Marking Spot Certified DNAse/RNase..250pcs

Capillary 580 MCRN "V" Type 70005-20606 HPLC *NEW*

D.I.S. 32 Gauge Needle Insert for HESI Probe 70005-60155 *NEW*

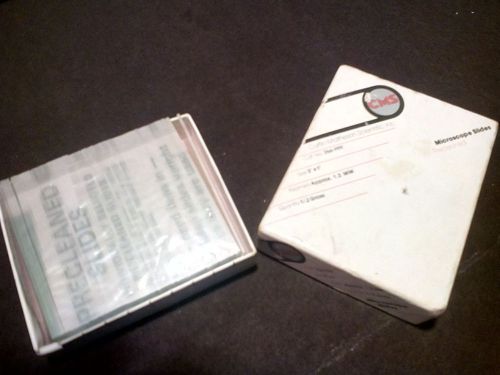

LABORATORY SCIENCE PRECLEANED MICROSCOPE SLIDES

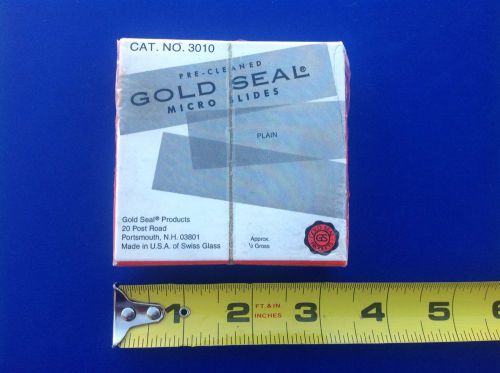

Rite-on Gold Seal Blank Microscope Micro Slides Pre-Cleaned Plain Cat. 3010 New

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies