US $120

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | DINGHUA |

Directions

Similar products from Soldering Irons & Stations

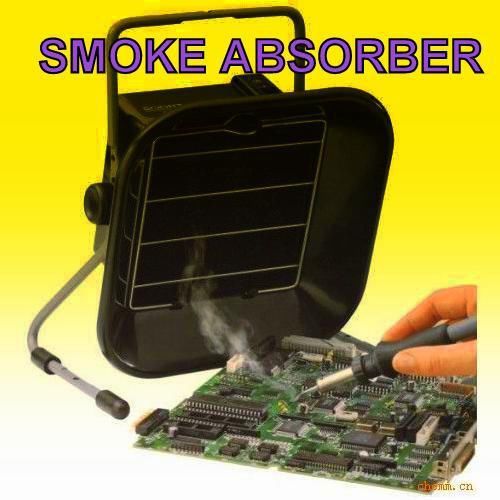

SOLDERING SMOKE ABSORBER type EDS 493 Fume Extractor, Vent

2in1 SMD Soldering ReWork Station HOT AIR & IRON 852D+ Free Items $20 value

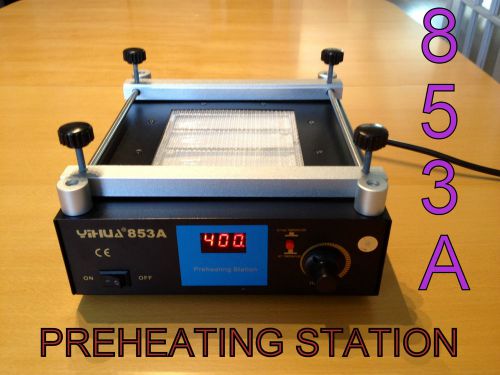

853A Digital Preheating Oven Station Local Pickup GTA

Pro ACHI Hot Air QFN MLF PGA BGA Soldering Infrared Rework Station

Sylvania modlel SS100 solder sucker

New Hexacon MP-948 Mini Solder Pot 800F 115V Tin Strip

Metcal QX2-P-11 Rework Station w/ AC-PH-11 Preheater & QX2-CT Controller TESTED

PDAS Handhelds PCB chipset Mounting desmounting station BGA rework C1 4800W

Tenma 21-11405 50W Rotary Dial Temperature Controlled Soldering Station

WELLER SOLDER STATION WTCP SERIES TC202 BASE & SOLDER IRON No Reserve

4PCS Hakko FG-100 Soldering IRON Tip Thermometer NEW

220V BGA Reballing Machine Air IR Soldering Station for Mobile phone laptop A06

Manufactural 4500W bga rework station tablet motherboard repairing machine 5830

220V Hot Air Vacuum Laptop BGA Rework Welding Station Digital Soldering Iron 390

Weller DS 701 EC Soldering/Desoldering Station Digital Display 120-240VAC 220W

Cooper Weller AG700D-N Hot Air Gas Soldering Station 75-240/24V NO IRON

PACE Parts 8887-0341-P10,1309-0028-P1,1265-0011-P1,1348-0547-P10,6021-0008-P1

(2) HAKKO 470-2 470 AIR DESOLDERING REWORK STATIONS PLUS NEW EXTRA SPARE PARTS

Weller Cooper Tools DTL1000 700F, 800F Dual port soldering sys. EC1201A w/3 tips

People who viewed this item also vieved

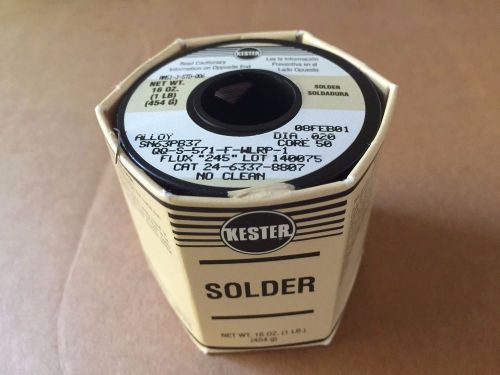

Kester Solder ~1 lb Solid Wire Alloy SN63PB37 QQ-S-571-F-WLRP Dia 0.020" Core 50

Kester Solder 1 lb Solid Wire Alloy SN63PB37 QQ-S-571-F-WS Dia. 0.015" Core SW

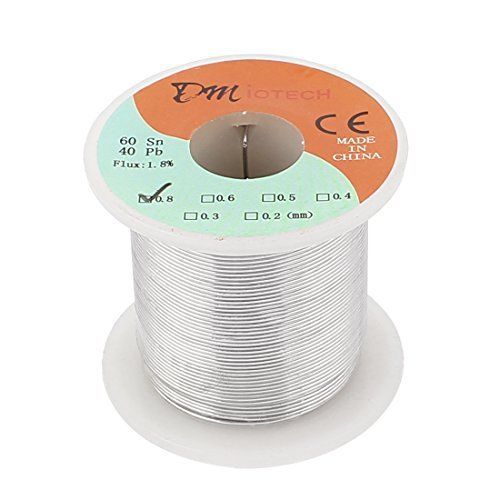

DMiotech® 0.8mm 200g 60/40 Rosin Core Flux Tin Lead Roll Soldering Wire

SRA Soldering Products SRA #80 Water Soluble Soldering Flux Pen - Refillable

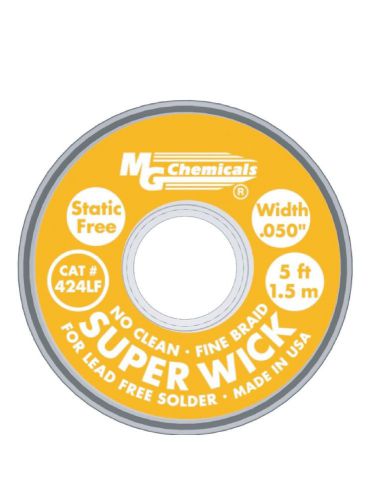

MG Chemicals Desoldering Braid - No Clean - Fine Braid Super Wick for Lead Free

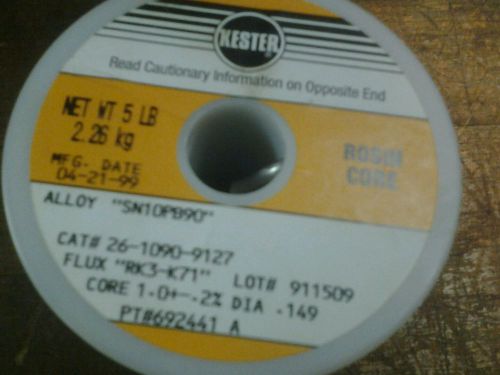

KESTER SN10PB90 SOLDER 5 POUNDS .149 ALLOY 90/10 LEAD

ChipQuik Flux No Clean Tack 10cc Syringe

Wahl Replacement Soldering Tip 7535 NIB

1Pcs Solder Screwdriver Iron Soldering Tip 900M-T-1.6D for 936 Station 900M

Pace Soldering Tip 1121-0564 Quantity 3

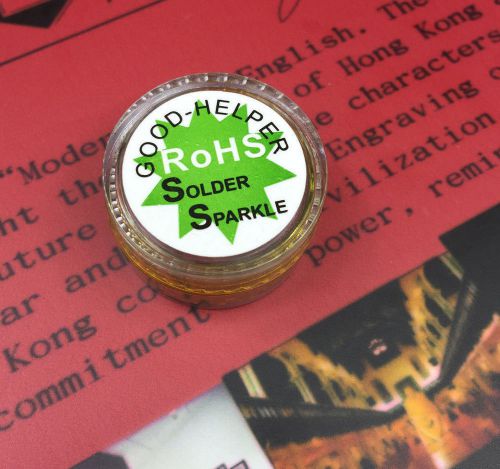

50g RoHS Solder Paste Sparkle Lead Free Sn42 /Bi 58 For BGA PCB Repair Welding

PX-60RT-1C goot Soldering Iron Replacement Tips PX-501 PX-601 RX-711 RX-701

LOT OF 19 WELLER SOLDER TIPS - SOME VINTAGE RARE HARD TO FIND

Weller PTK7 .046" x 1.0" x 700F Long Screwdriver Tip for TC201 Series Iron

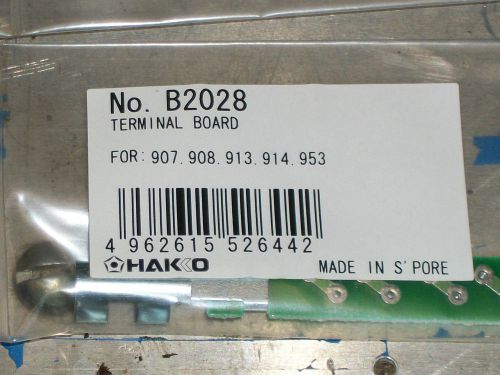

Hakko B2028 terminal board for 907, 908,913,914,953 NEW

Hakko FM2024-42 Desoldering Iron Upgrade Kit for FM-Series Stations

MG Chemicals 472 Series #2 Fine Braid Super Wick with RMA Flux, 500' x 0.05"

MG Chemicals 463 Series #3 Fine Braid Super Wick with RMA Flux, 100' x 0.075"

MG Chemicals 454-NS Series #4 No Clean Super Wick Desoldering Braid, 0.1" x 50'

MG Chemicals 425-LF Series #3 High Temperature Super Wick For Lead Free Solder

MG Chemicals 424-LF Series #2 High Temperature Super Wick For Lead Free Solder

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies