US $5300

Directions

Similar products from Other Processing Tools & Machinery

CHEMINEER MIXER SIZE12 HTN 36-1

CHEMINEER MIXER #13HSB 46-1 SURPLUS

HEAVY DUTY BLENDER / GRANULATOR / MIXER STAINLESS STEEL

PHILADELPHIA MIXER PVE140 26-1 RATED 350 HP

FREESHIPSAMEDAY 2X MICROFLEX MSA-028-211 r6 2 HOLES MICRO SEAL MSA028211 NEW BAG

SPENCER 25 HP BLOWER cat # 30104CI, 277923

HOFFMAN BLOWER #77205A-5/202 VERY LARGE # MD19420

HEAVY DUTY TRAYNOR BRAND TANK ROLLERS - BEARING TYPE

FREESHIPSAMEDAY 2X MICROFLEX MSA-028-111-M r7 1 HOLE MICRO SEAL MSA028111M NIB

Gast Rotary Vane Vacuum Pump, Model 0523-545Q-G582DX

FREESHIPSAMEDAY 2X MICROFLEX MSA-028-311 r6 3 HOLES MICROSEAL ASSY MSA028311 NIB

SCRAP MASTER 1500 BOLSTER MOUNT PNEUMATIC CONVEYOR DRIVE AIR BELLOWS TECHNOLOGY

Cable ADVANTEST DCB-EPA129X01A-1 CABLE

Cable ADVANTEST DCB-SSA172X01B-1 CABLE

Cable ADVANTEST DCB-EPA130X01B-1 CABLE

Cable ADVANTEST DCB-SSA160X08D-1 CABLE

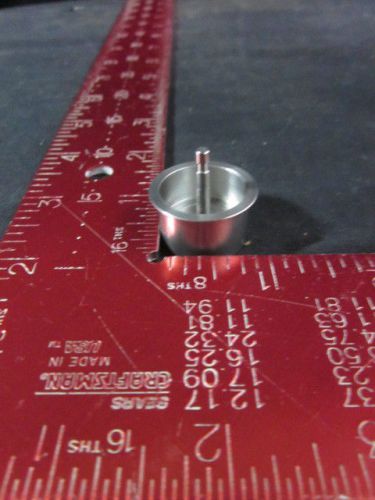

Tool Applied Materails (AMAT) 0020-63356 GAUGE, ALIGNMENT, CHAMBER/LID RIGHT, 20

OEM Part Electro-Graph 25278 Plansee Cathode IHC VER 7 Varian E17295630

People who viewed this item also vieved

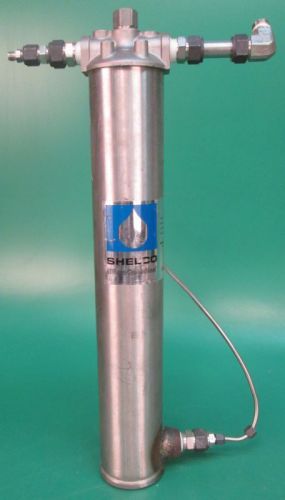

ST30 FOS-806DUB-316 MicroGuardian Custom Filter Filtration MS20 Cartridge Type

FILTERITE PALL T8740085000 PFT 0.8-9.75UV-M10 Filter

MEMTEC FILTERITE 8739715000 PFT 0.2-10UE Filter

Filterite PALL T8752857000 PFT 5-4UV-M3 Filter

LIGHTNIN SANITARY MAGNETIC MIXER electric motor MBI410H37 CW Bottom Mount

NEW CHEMINEER 1 HP MIXER / AGITATOR GEAR REDUCER MODEL 1-HTNS-1 56 RPM OUTPUT

NEW CHEMINEER 10 HP MIXER GEAR DRIVE 1750 RPM 155 UNIT RPM 3-HTA-10

60 Gallon Scott 316L Full Vacuum Triple Motion Turbine Reactor

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies