US $19000

Directions

Similar products from Tools for Milling Machines

1-1/4" SHELL / FACE MILL ARBOR w/ NMTB40 SHANK

4 ENDMILL TOOL HOLDERS w/ NMTB40 SHANKS - 3/8", 1/2", 3/4", 7/8"

NOS MILLING MACHINE DOUBLE CAM LEVER HANDLE LOCK 5/8" 5-3/8"

Intelitek Light Machines Benchtop CNC Milling machine. Sherline. Make Offer

NICE R8 SHELL END MILL MILLING ARBOR 1" SHAFT W/ 3 SHELL MILLING CUTTERS

ETM R8 STUB MILLING ARBOR 1" SHAFT LEFT HAND THREAD

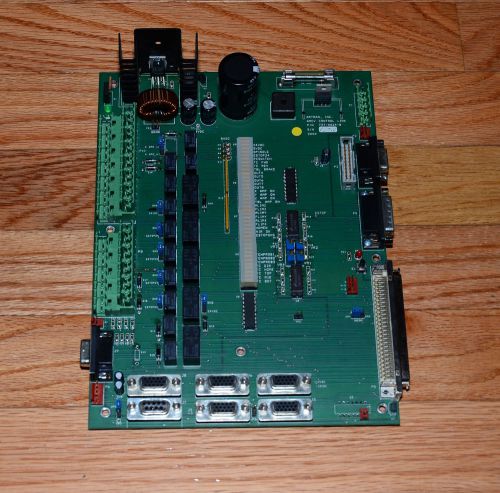

Artran Inc. AMCV Control Link Board P/N 727-0064-B

NIAGARA B3 2-1/ 2X5 / 8X1 Milling Cutter (NOS) HSS US MADE

Quatro High Shear In-Line Emulsification and Wet Milling "colloid" machine, Z5

BIG LOT OF HOLD DOWN TIE DOWN CLAMPS W\RACK USA VULCAN

DECKEL FP2 Shaper/Slotting Head

LOT OF ERICKSON NMTB 30 QUICK CHANGE TOOL HOLDERS W/ DA COLLETS

Sandvik Coromant R365-125Q40-W15H CoroMill 365 Face Milling Cutter, Steel, Right

Iscar Multi Master LOT 3 SHANKS AND 1 BOX INSERTS

Valenite GTE Master Mill Face 6" Insert MM-060-10R-150F

SUMITOMO SECE61791 INDEXABLE ENDMILL DIA 37 8-15NT_2

KEITH LAWRENCE MILLING BLOKS 1x2x3 EXCELLENT

WIDIA M750 1.539.85.004.00 INCH D=10 HEXACUT MOUNTING FLANGE

SUMITOMO INDEXABLE ENDMILL DIA 25MM (0.9842") OAL 165mm (6.4960") WEX2025EL24

SUMITOMO INDEXABLE ENDMILL DIA 40MM (1.5748") OAL 220mm (8.6614") WEX3040EL

People who viewed this item also vieved

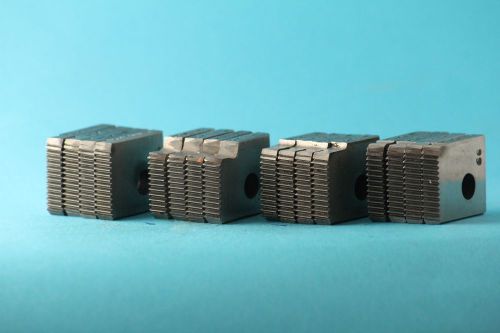

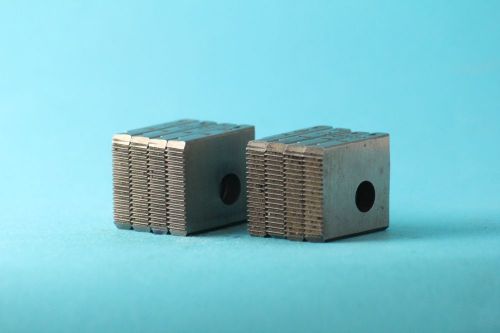

H&G STYLE 1/4"-28 CHASERS, 100 SERIES, 2 SETS

H&G STYLE 10-32 CHASERS, 100 SERIES, 4 SETS

H&G STYLE 10-32 CHASERS, 100 SERIES, 2 SETS

Procunier 1TT Tapping Head Atachments.

GREAT RUNNING JOHANSSON TOOLROOM RADIAL DRILL 4 MT SPINDLE VIDEO INSIDE

10-32 X 1.5D (.285") Stainless Screw Lock Inserts, MS21209F1-15

JAPAX EDM FLUSH CUPS MGX OEM#5006-1 LXR,LV3,LUX3 UPPER

MITSUBISHI EDM FLUSH CUPS FOR OEM # M063 UPPER/DWC100

JAPAX EDM FLUSH CUPS MGV FOR OEM #0003-01 LDMS LOWER

**Buffalo #0BR Angle Bending Rolls

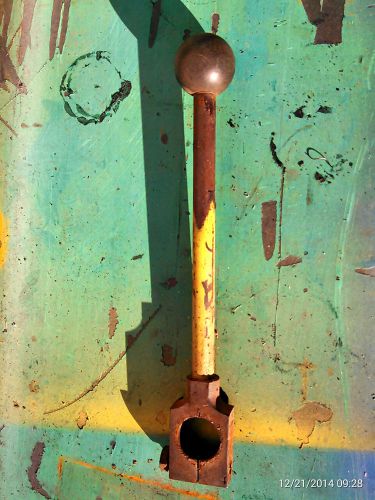

DIACRO 24" Finger Break Parts - Clamp Handle assembly

DIACRO 24" Finger Break Parts - Folding Bar Stop

new ELLIOTT TOOL TECHNOLOGIES SKB04500M04 45mm Skiving Cage roller bushing

new ELLIOTT TOOL TECHNOLOGIES SKB07500M04 75mm 2.953 Skiving Cage roller bushing

new ELLIOTT TOOL TECHNOLOGIES SKB05500M04 55mm Skiving Cage roller bushing

INDUSTRIAL SERVICES D6A2H 6D180-N50-BA-1/8-M DIAMOND DRESSER WHEEL

Brand New Milwaukee 2780-21 Fuel Brushless Angle Grinder Kit Authorized Retailer

PARKER MAJESTIC SURFACE GRINDER

South Bend 9" Model A Bull Gear And Back Gear Guards

South Bend 9" Lathe Pully Tension Afjuster

South Bend 9" Lathe Tension Lever

SM Engineering 6" Straight Through Annealing Belt Furnace W/ Ammonia Dissociator

Vidmar 10-Door Heavy Duty Storage Cabinet - Very Nice Condition!

Flagler 18 gauge Heavy-Duty High-Speed 7-Station Pittsburgh Machine

NICE Peerless Vertical Band Saw Model HVC-20, 20" Capacity Variable Speed Welder

NICE GROB MODEL NS-60 VERTICAL BAND SAW BUILT IN 1959 TAKE A LOOK

DoAll Vertical Metal Band Cutting Saw Model 26-3 - No Reserve!

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies