US $500.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | Milton Roy LMI |

| Country/Region of Manufacture | United States | ||

| Model | Liquipro AA966-362TI | ||

| NEMA 4X/IP65 Enclosure | Industrial Grade IP-68 | ||

| MPN | AA966 |

Directions

Similar products from Vacuum & Liquid Pumps

Prominent Fluid Controls G/4b 1601PP1000D20001 Solenoid Metering Pump

^^ Varian 951-5091 RIGHT ANGLE VALVE WITH FLANGE

Semi-Gas Systems Nanochem 1400 Vacuum Chamber Purification System

PERKIN ELMER OV1020115702 SERIES 200 PELTIER OVEN 300VA 120-240V-AC B325427

FMI RH-B-12VDC LAB PUMP JR. Fluid Metering Lab Pump RH00 Head

SIMON MANOSTAT PRECISION VARISTALITIC PUMP CAT # 72-360-000

MKS BARATRON HEAD 100 TORR- 310CH-100

Hastings Vacuum Gauge 0461 w/ DV-6 Gauge Tube

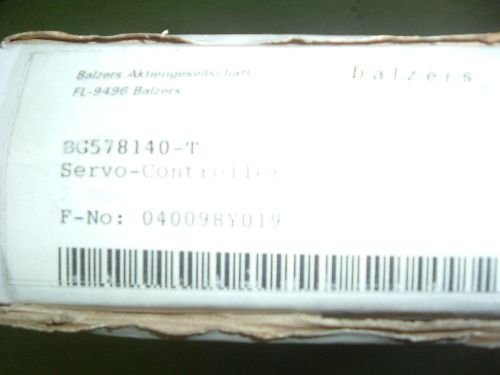

BALZERS VACUUM BG578140 T SERVO CONTROLLER MODULE NEW BOXED

Belt-driven Vacuum Pump Welch 1402

HIGH VACUUM FLEXIBLE STAINLESS STEEL TUBE TUBING~19.5" W/CLAMPS (S16-2-64C)

Cole Parmer Masterflex Peristaltic Pump Great Condition

KNF NEUBERGER LABOPORT PM23939-816.1.2 230VAC VACUUM PUMP M37 MOTORTYP

Hospira LifeCare PCA3 Infusion Pump Lab Diagnostic Exam

Abbott Omni-Flow 4000 Plus Pump I.V. Medication Management System Lab Diagnostic

Abbott Micro Macro Plum XL Infusion Pump 11859-04-04 Lab Monitoring

Genesis Ebara Cryopump Cryogenic Vacuum Pump ICP Series Motors +Lot of 7+

Genesis Ebara Cryopump Cryogenic Vacuum Pump ICP-300L Low-Profile 2500 LPS Argon

People who viewed this item also vieved

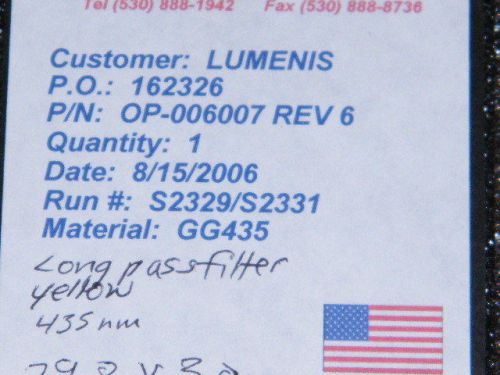

Schott GG435 30.0mm x 3.1mm Visual & Infrared Longpass Filter, UV Block 435nm

Sigma water wastewater sampler

X-RAY Light Box Model 202 Double Panel - American Medical Association

AmScope Sharp Stereo Microscope 20X & 40X

Newport 850G Series Motorized Linear Actuator #O8

DICKSON TM320 Temperature & Humidity Data Logger with Digital Display NEW

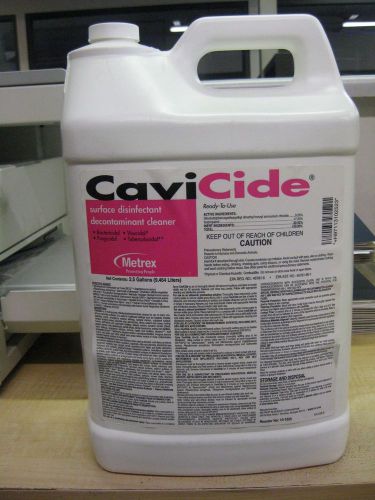

Metrex Cavicide Surface Disinfectant 2.5 Gallon Bottle Item 13-1025 C/2

Biospec Products Mini Beadbeater-8 in working order

New Brunswick 25 Series Door Gasket for Incubator Shaker Model G-25

#QL1 Talboys T-Line Laboratory Stirrer Model 101 Continuous Duty

Reichert-Jung FC-4E Autocut Microtome

Boekel Scientific Stainless Steel Dricycler Desiccator M/N: 134241 dessicator

2016 CE Dental Equipment High Pressure Steam Cleaner cleaning 22L 0.4Mpa +alarm

Ault Medical Power Supply MW122RA1223F02 8Pin 12V 10A

Inheco TEC control 96 / RS 232 TEC control shaker interface

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies