US $3,299.00

| Condition | Used

:

An item that has been used previously. The item may have some signs of cosmetic wear, but is fully operational and functions as intended. This item may be a floor model or store return that has been used. See the seller’s listing for full details and description of any imperfections.

|

| Seller Notes | “Load tested & ready to weld.” |

Directions

Similar products from Electric Welder Machines

Miller Dynasty 200 DX TIG Welder w/ Fingertip Control, Air Cooled - 951175

LINCOLN Power MIG 256 Welder (230/460/575) K3068-2

THERMAL ARC FABRICATOR 190 208V MIG-WIRE FEED WELDER W1001500 L@@K-SAVE!!!

LaserStar iWeld Professional Pedestal Laser Welder 970 Series G3 |2012| Great!

Airco 250 Amp AC/DC Heliwelder Welding Machine w/Spare Pedal

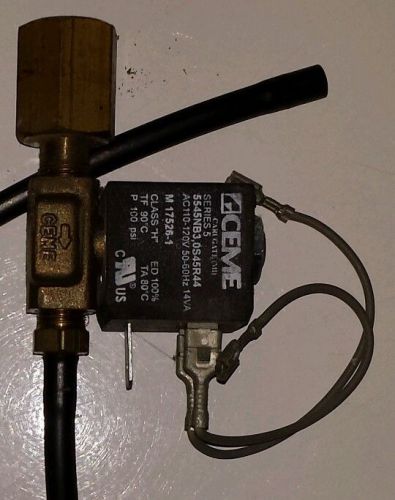

Lincoln Mig Welder Gas Solenoid Assembly

Miller Syncrowave 300 Welder (Inv.31822)

L-tec 225 wire feed welder (Inv.31823)

Lincoln Powerwave 355M & 10M Feeder Multi-Process MIG Welder Complete PKG 230V

Miller Dimension 452 & DUAL Feeder Multi-Process Welder Complete PKG

LINCOLN SAM650 PORTABLE WELDER WITH STOODY BUILD UP WIRE FEEDER WITH MOTORS

Miller Big Blue 400 907175 Welder Generator with trailer

Craftsman Professional Model 20559 MIG Wire Feed Welder

Miller XR Control Extended Reach Push-Pull Wire Feeder MIG Welder

AMERICAN WELDQUIP INC. 300-ROBO WELDER HEAD AW-75/35601-I

Hobart Champion Elite 11,000-Watt Gas Engine-Driven Welder/Generator 500562 SAVE

Thermal Dynamics/Victor Technology Remote Pendant

Treadlite foot pedal cat no t-51-s

ABICOR BINZEL TORCH NECK ROBO VTS 290 22

People who viewed this item also vieved

Vintage Craftsman Welding and Cutting Torch Model 624.54290

Victor No. 7 T4 Welding,Heating Tip,Fits 300 series torch body,GOOD #V110515

Anderson Greenwood Brass Valves And A Petes Plug

Hobart Bros Brothers Welder Brushes 554

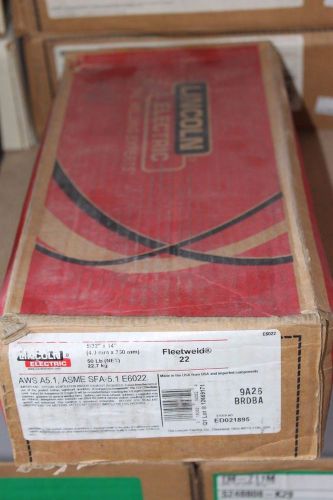

Lincoln Electric 5/32" E6022 Fleetweld 22 Welding Rod 50 LBS. ED021895

Erico CA15PLUSF33 CADWELD PLUS Weld Metal - Quantity 33

FOREDOM DP-30 DRILL PRESS STAND

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies