US $390

Directions

Similar products from Other Heating, Ventilating & Air Conditioning Items

BARELY USED GOODWAY SOOT-A-MATIC SAM-3 BOILER TUBE CLEANER LIGHTLY USED

Yellow Jacket R22/410/404Charging Manifold-Gauge & Hose Set

Malco C5 Pipe Crimper HVAC Made in USA EXCELLENT!!

UEi Test Instruments SSM1 Super Heat/Sub Cool Meter

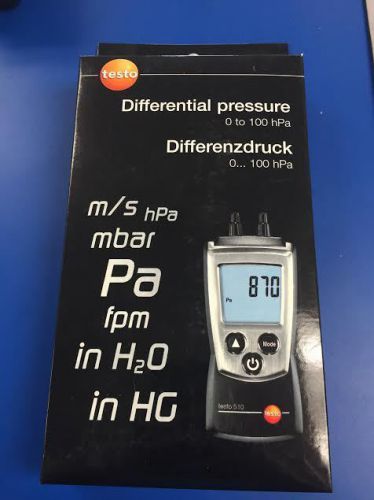

TESTO 510 DIFFERENTIAL PRESSURE MANOMETER

Dwyer 490-1 Wet/Wet Handheld Digital Manometer Liquid and Gas Pressure 0-15 psi

Ritchie Engineering Co Inc. Yellow Jacket 60210 Flaring Tool Part dq

INFICON CO CHECK CARBON MONOXIDE METER 715-202-G1 USED VERY GOOD COND. 11TN45

Analog Deep Vacuum Gauge Manometer Size:2.5"SS Case 1/8"NPT 0-30"Hg Pump System

Robin air Process Tube Adapter Kit Part Number 12458

MALCO S-6 6" X 1 1/4" METAL SEAMER TOOL-U.S.A.-7" HANDLES-SHEET METAL-HVAC-NR

Appion TEZ8 8CFM 2 Stage Vacuum Pump

YELLOW JACKET PLUS II 21150 50' CHARGING HOSE NEW AND UNUSED WITH TAG

Dual port differential manometer

Robinair (65360) Enviro-Guard Hose with Ball Valve - 60", Red

Tight Quarter Tube Tubing Cutter:Copper+1/8-7/8"Plumbing AC/HVAC Tool Rust Proof

T-Adapter Size:1/4X1/8X1/4"Add Gauge at Deep Vacuum Pump/Manifold NPT/Flare HVAC

MALCO MODEL HC1 ADJUSTABLE 2"-12" HOLE CUTTER HVAC TOOL

People who viewed this item also vieved

Pre-Owned Yellow Jacket Titan Manifold 4 Valve HVAC Gauges

Yellow Jacket 78020 Fuel Oil Test Kit 30" 0-150 lb. scale 12" hose, fittings NEW

Fieldpiece SMAN360 Digital Manifold Gauge (EL)

Westwood T10 Pressure View Oil Burner Pump Tester - New

TEK-Mate Portable Leak Detector Used

TIF 5750A Halogen Leak Detector tested works, good condition

Combustible Gas Detector TIF 8900

Johnson Controls RLD-H10G Universal Service Leak Detector

Inficon Refrigerant Leak Detector D-tek Select Carrying Case

APPION G5 TWIN REFRIGERANT RECOVERY MACHINE

Fluoromizer Model 6000 Refrigerant Recovery System

YELLOW JACKET R60 RECOVERY SYSTEM RECOVER X + Gauges,Hoses,Parts,Repair

NEVER EVEN OPENED! APPION G5-TWIN REFRIGERANT RECOVERY MACHINE

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies