US $49.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

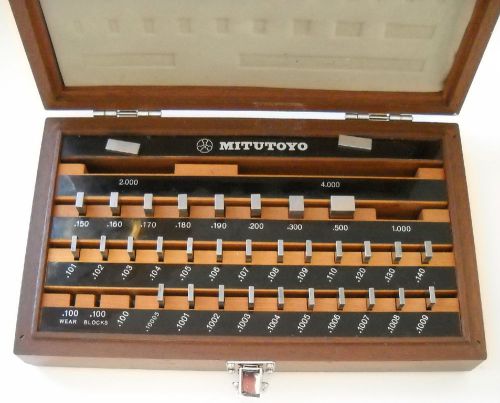

Brand | Mitutoyo |

| MPN | 611824-531 |

Directions

Similar products from Measuring Gage Blocks

SET of 10 MACHINIST SETUP / GAGE GAUGE BLOCKS tools *0

LARGE LONG SINGLE PARALLEL HARDENED STEEL machinist tools *Y

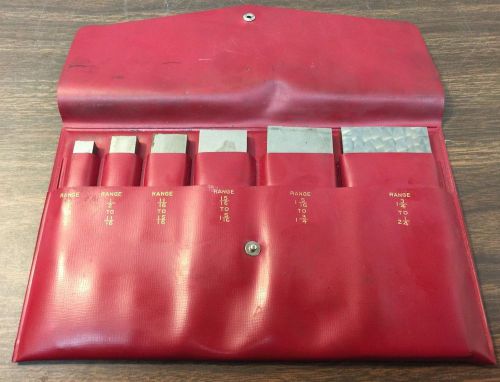

ASSORTMENT of MACHINIST PARALLELS & STEEL machinist tools *A3

Vintage STARRETT 270 Taper Gage Measuring Range: .010"~.150",0.3mm~4mm

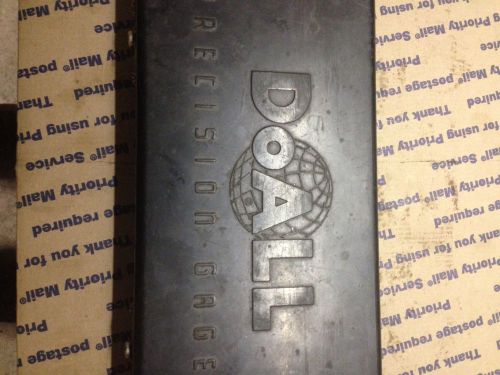

Machinist tools,Doall gauge block set

Mitutoyo - Digimatic Micrometer (.00005" / 0.001mm) No. 293-832

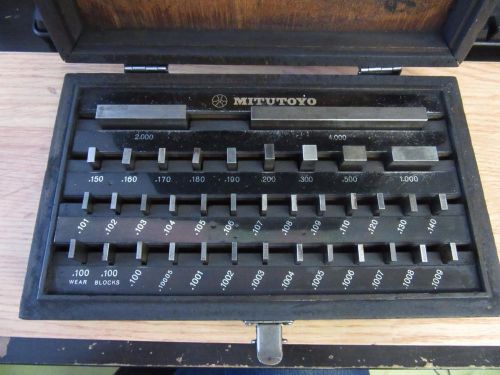

Mitutoyo Gage Block Set #BE1-35-3 Grade 3 Partial Set Nice Case

Ten Pc. 1/8" Parallel Set 1/2" to 1-5/8"

Fowler gauge block set 65 Pieces HDT Inc.FED Grade 3 wood case missing a few

Gauge Block set 79 Pieces with wood case missing two blocks minor surface rust

Mitutoyo Gauge Block 0.50 mm, Brand New

Mitutoyo Gauge Block 0.75 mm, Brand New

Mitutoyo Gauge Block 1.5 mm, Brand New

Lufkin 915 Adjustable Parallels Matching Set 6 Piece

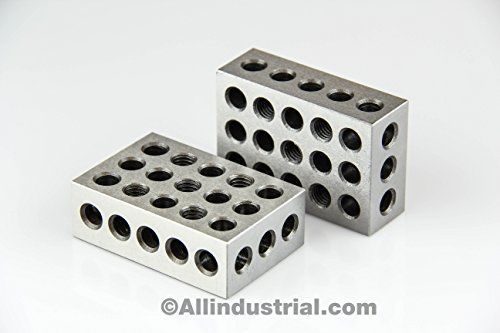

NEW BL-246 Pair of 2" x 4" x 6" Precision Steel 2-4-6 Blocks

Lot Machinist Webber DoAll Steel Rectangular Gage Blocks 6 pieces .450,.138,.140

TTC 81 Piece Precision Gage Block Set .1001" thru 4" Grade: A+

GAGE Block Set No. 4238 Grade B 79 pcs

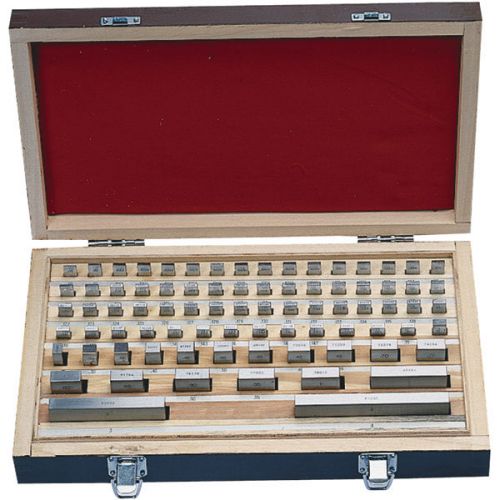

40 PC SPACER GAUGE BLOCK SET .050'' - 1'' MACHINIST TOOL WITH WOODEN CASE

MACHINIST ANGLE GAGES GAUGES 1 - 30 DEGREES in WOOD BOX *20

People who viewed this item also vieved

Mitutoyo Gage Block Set 516-914 Grade A+

Shinwa 13021 Silver Finish straight long JIS1 grade 60CM Ruler Metric Fr Jp

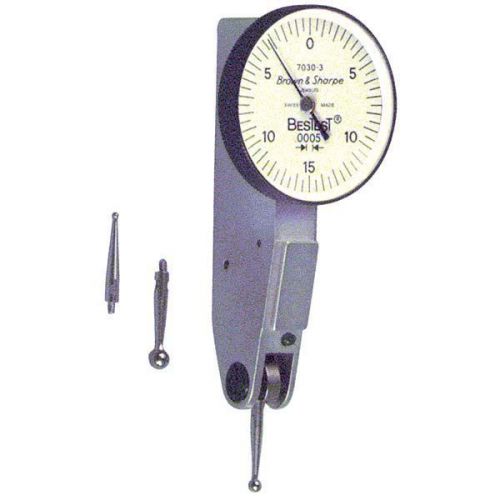

BROWN & SHARPE 599-7033-13 BesTest Dial Test Indicator

BROWN & SHARPE 599-7032-13 BesTest Dial Test Indicator

14" JONES & LAMSON Tec 14 Optical Comparator (New 1996)

Free Optical Comparator diagnosis and technical repair advice (803) 329-5123

Brown & Sharpe .5 - .6"/.0002" Intrimik/Bore Micrometer w/ case - FC28

STARRETT 436 2" MICROMETER TOOL 2" NO BOX

Chesterman Sheffield No 960F 24 inches tempered Machinist Ruler

Starrett 661 Mini Magnetic Indicator Holder W/ 3/8" Stem or STD Dovetails,

Starrett PT17850 Indicator Holding Rod for Magnetic Base Holder, 3/8"

Starrett No. 657 Magnetic Base (931-3-E)

Starrett No. 657 Magnetic Base (931-3-D)

Fowler Bevel Edge Square 200mm (8") x 130mm (5")

VINTAGE LUFKIN RULE 6" SQUARE NO 2507R-WITH SCRIBE- LEVEL BUBBLE NOT WORKING

Starrett C19 Chrome Protractor

Mitutoyo Universal bevel protractor Stainless Made in Japan

MOJAVE GRADE B 48" x 36" x 6-1/4" THICK GRANITE SURFACE INSPECTION PLATE

L.S. STARRETT LABORATORY GRADE 96"x48"x12" PINK GRANITE SURFACE INSPECTION PLATE

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies