US $750.00

Directions

Similar products from Movement Monitoring & Control

ROBOHAND RP-100P X940602 - 1" PARALLEL GRIPPER PNEUMATIC - *UNUSED* Qty:1

ROBOHAND RP-40P X931114 - 1/2" PARALLEL GRIPPER PNEUMATIC - *UNUSED* Qty:1

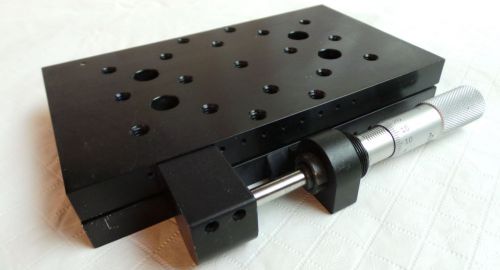

NEWPORT 435 (3.5 x 6) Stage with 25mm Starrett Micrometer

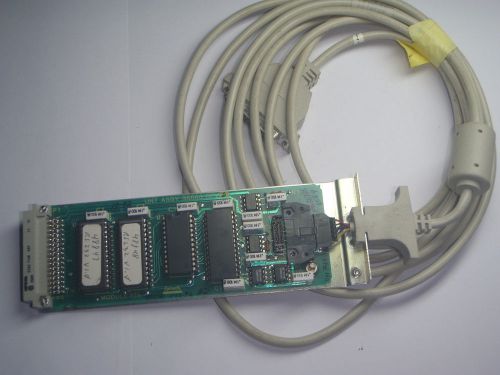

ZYMARK 38663 Rev 6 E1A Controller Module With Cable

PALMGREN X Y Table with Tilt 6" X 10" #6284-1

Newport ESP-301-3G motion controller

Thorlabs MBT616D 3 axis micro block with differential positioners

Oriel 18019 Motor Mike Actuator, Pair of Actuators

Aluminum Precision Rotary Stage Rotational Micro Model Klinger Controle 3/8"

Vexta 2 Phase Stepping Motor, PH 268-21-C8

Shinamo Kenshi Stepping Motor, SST39C1030

Superior Electric Slo-Syn Synchronous Stepping Motors, MA61FC-82007, (Lot of 2)

Minebea Stepping Motor, 15PM-K003-04

Elwood Gettys Stepping Motors, Model 23D6151E, (lot of 4)

Vexta Stepping Motor, PH266M-E1.2

Vexta, 4CSMGK-101, Stepping Motor

Elwood Gettys Stepping Motors, Model 23E6102AM, (lot of 2)

MAXON DC Motors X 3, model 2028.945-62.1 31-025

People who viewed this item also vieved

Optical Newport VPH Post Holders

Nasco 184 oz Whirl-Pak Sample Bags (15” x 20”)w/ White Write On Stripe

New DRY Darkfield Condenser Compound Microscope Dark Field Live Blood Analysis

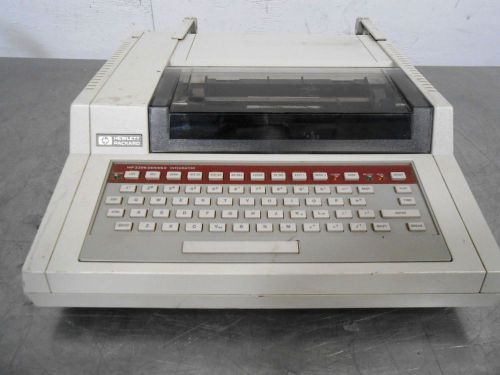

H117094 HP Model 3396B Series II Integrator

Cole-Parmer Hygrothermograph 8369-50

Leitz Dialux 20 Trinocular Microscope, fluorescence, camera, accessories

Mityvac Automotive Vacuum Pump/Brake Bleeder kit, container, manual, tubing

ATTEST BIOLOGICAL INCUBATOR DRY 3M (NO CORD)

High quality Spectrum Calcium Carbonate 500g

Stem Corporation RS1050 Laboratory Chilling and Stirring Block System

IKA VWR Color Squid Magnetic Stirrer

Buchi B-481 Rotovapor Water Bath Waterbath

HARRICK PLASMA CLEANER STERILIZER PDC-32g

VWR Scientific Accupower 300 Power Supply

VWR Orbital Shaker 980001, 12.5 x 10.5 Inch , 115 V

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies