US $40.00

Directions

Similar products from Other Bags & Packets

4X4 Plastic Bag With Hang Hole CENTURION INC Plastic Bags 1180 701844123916

2X3 Plastic Bag With Hang Hole CENTURION INC Plastic Bags 1177 701844123886

3X5 Plastic Bag With Hang Hole CENTURION INC Plastic Bags 1179 Light Clear

25 White Sandbags w/ ties 14.5x26 Sandbag Bags Heavy Duty

4X6 Plastic Bag With Hang Hole CENTURION INC Plastic Bags 1163 701844123923

6X9 Plastic Bag With Hang Hole CENTURION INC Plastic Bags 1183 701844123930

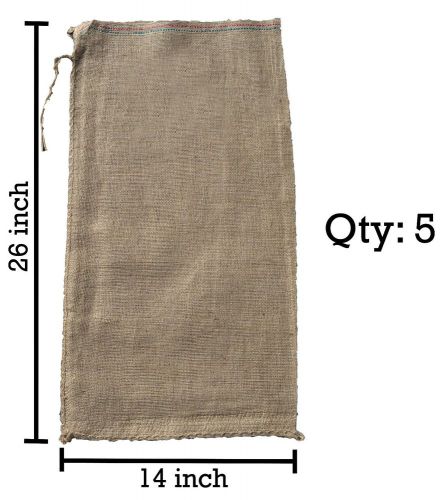

5 14x26 Burlap Bags, Burlap Sacks, Sandbags, Gunny Sack, Potato Sacks, Sack

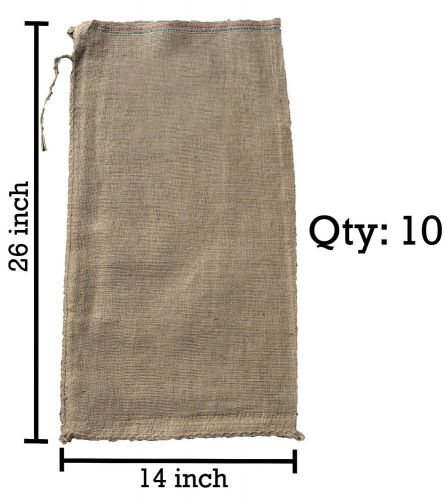

10 14x26 Burlap Bags, Burlap Sacks, Sandbags, Gunny Sack, Potato Sacks, Sack

100 clear plastic doorknob bags Laddawn 5.5" x 16" .4mil thickness Free Shipping

3M STATIC SHIELDING BAGS 48" X 36"

1000 -12" x 17" Clear Produce Bags w/Header Pack

BLUE JUMBO REUSABLE CONTRACTOR CLEAN-UP STORAGE CAMPING GARBAGE BAG T-SHIRT LOT

Black Merchandise Handle Bags~90 Ct.~8" x 15"*Great to hide gifts in*

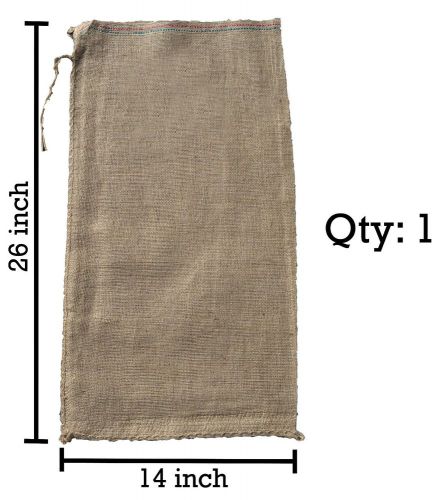

1 14x26 Burlap Bags, Burlap Sacks, Sandbags, Gunny Sack, Potato Sacks, Sack

2X2 Plastic Bag With Hang Hole CENTURION INC Plastic Bags 1176 701844123879

1000 NEW White 100% Polypro Sandbags w/Tie-String 14x26 50lb Capacity Sand Bags

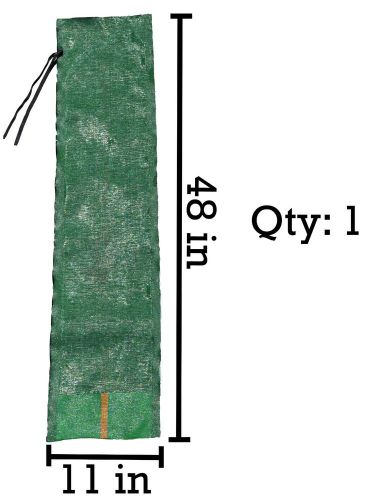

Sandbaggy -1 -11x48 Long-Lasting Empty Sandbags For Sale- Sandbag Sand Bags Bag

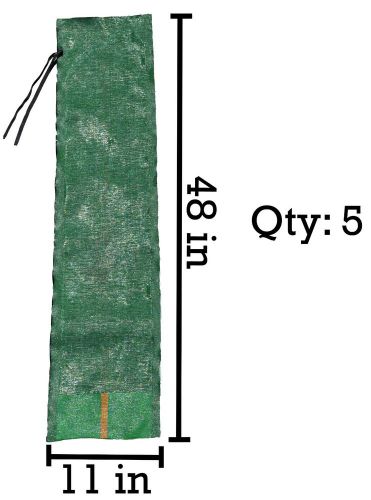

Sandbaggy -5 -11x48 Long-Lasting Empty Sandbags For Sale- Sandbag Sand Bags Bag

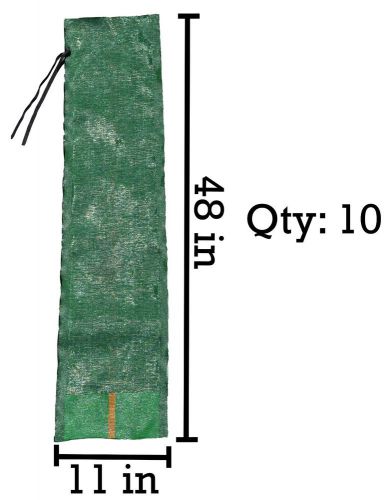

Sandbaggy -10-11x48 Long-Lasting Empty Sandbags For Sale- Sandbag Sand Bags Bag

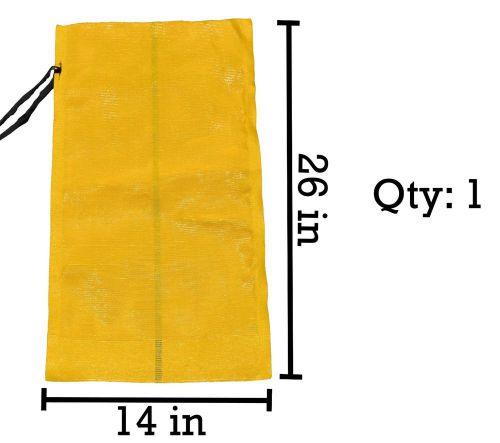

Sandbaggy -1 -14x26 Long-Lasting Empty Sandbags For Sale- Sandbag Sand Bags Bag

People who viewed this item also vieved

LK 20G-042012, 4x2x12 Side Gusset Poly Tube Bags 1,000 10x100 FDA 2 MIL

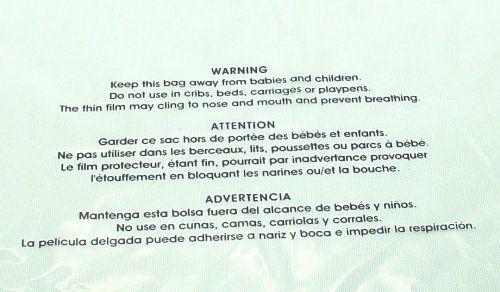

Suffocation Warning Poly Bag, 1.5ml Self-sealed, 100 Count 9 X 12

Uline 14" x 20" Self Seal Poly Bags, Easy Peel and Stick Clear, 1.5 mil

Kraft Tin Tie Coffee Bags 1lb 45 pcs Brown

Black Real Genuine Leather Women Wallet Carteira Carteras Coin Card Purses!

Brown Real Genuine Leather Women Wallet Carteira Carteras Coin Card Purses!

100 3"x 12" Ziplock Bags Reclosable Bags Clear 2 Mil Poly

Plymor 2" x 9", 2 Mil Clear Zipper Reclosable Storage Bags, DispenserBag Pack of

100 ESD Anti-Static Shielding Bags, 5"x8"in (Inner Diameter),Open-Top, 3.1mil

100 ESD Anti-Static Shielding Bags,Metal In, 4"x6",Open-Top, 3.1mil, For 2.5"HDD

55-Gallon Drum Anti-Static Poly Dust Cap - Pink (4 mil) (100 Bags)

6' x 2200' Anti-Static Low Density Poly Film - Pink Tinted (1 mil)

5-Gallon Pail Anti-Static Poly Dust Cap - Pink (4 mil) (100 Bags)

Plastic Merchandise Shopping Bags Clear Flowers Portable Handbag Grocery Pouches

LOT of AVON White Plastic Bags ~ NEW~Size large, Small & Clear

Duro 6 lb. Recycled White Paper Bag - 500 per pack

Duro 4 lb. Recycled White Paper Bag - 500 per pack

Halulu 100pcs 16x6x12 White Paper Retail Shopping Bags with Rope Handles

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies