US $520

Directions

Similar products from Carbide Inserts & Face Mills

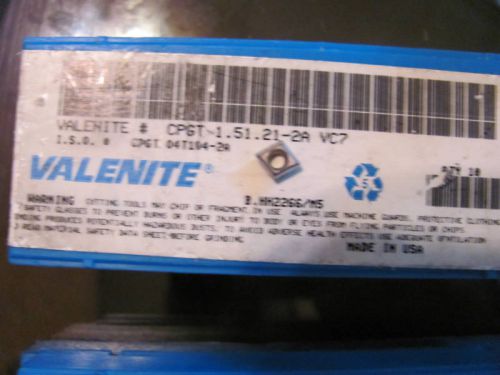

Valenite CPST 1.51.21-2A VC7 Carbide Insert

SECO VNMG 333 MR4 883 Carbide Insert

Manchester WCMX 040204-MIA PD51 Carbide Drilling Insert

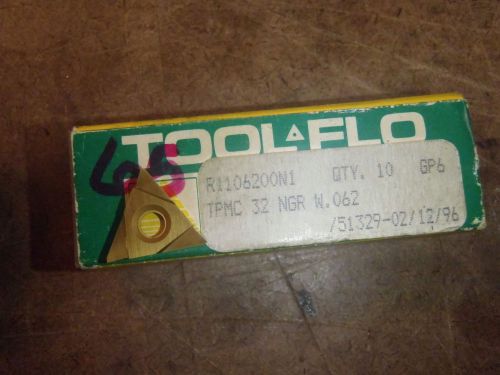

Tool Flo TPMC 32 NGR W.062 GP6 Carbide Grooving Insert

SECO VNMG 332 MR4 883 Carbide Insert

Tool Flo TNMA 54 NV GP25 Carbide Threading Insert

** SALE ** CCMT 21.51 F1 TP40 SECO *** 10 INSERTS *** FACTORY PACK ***

New 10pcs Parting & Grooving Insert DGN 3102C IC354

ISCAR GSFN 2 IC 328 20pcs --Slitting Inserts

10 Cnmx 120704-M4 IC806 ISCAR CARBIDE INSERTS

MT4 22mm Morse handle, handle, link rod for BAP / EMR / RAP..

4 VALENITE CARBIDE INSERTS DCMT32521A SV310

5 NEW SECO CARBIDE INSERTS SNMG 190612-M5 TX150

DNMG 19 06 08 PR 4225 SANDVIK Insert

FREE SHIPPING SANDVIK DCMT 070204-MM 1125 40pcs

CPMT 3-2 PF IC907 ISCAR Insert

Ingersoll SHLT1405APTN-HR IN1030 **

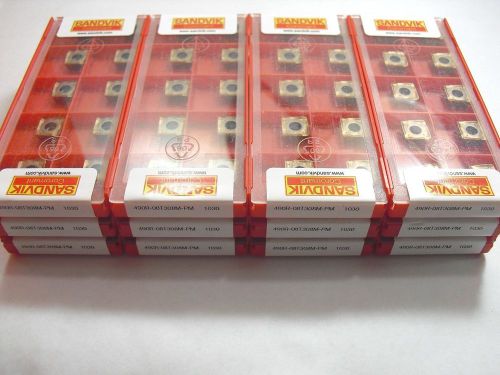

490R 08T308M-PM 1030 SANDVIK Insert

WNMG 432 MR7 TK2001 SECO Insert

People who viewed this item also vieved

duMONT Keyway Broach, 1"-F, Used

duMONT Keyway Broach, 7/8-F, Used

KORLOY SPET 050203 - DA H01 Ceramic Inserts NEW

KORLOY TCGT 1.81 .51 - AK H01 Ceramic Inserts NEW

NIAGARA 1/2" 4 FL DOUBLE END AITiN End Mill "BRAND NEW" EDP# N89901

3/32" 4FL DOUBLE END STUB LENGTH CARBIDE END MILL

17 MIXED PRECISION TWIST DRILL HSS TAPER SHANK DRILLS LOT

carbide bur set double cut 1/8 inch shank made in USA

Roper Whitney No.7 A XX Die 5/64" .080 Machinist Fabricator Sheet Metal Punch

Roper Whitney No.10 / 12 Punch 17/32" .266 Machinist Fabricator Sheet Metal Hand

Yankee 433-0.8125" 13/16" Chucking Reamer HSS 8 Straight Flute & Shank

Good 0.9375" 15/16" Chucking Reamer HSS 8 Straight Flute Taper Shank Cleveland

LOT OF 20 SLITTING AND SLOTTING SAWS 2-3/4" TO 3" WITH 1" BORES MALCO CLEVELAND

MACHINIST TOOLS LATHE MILL Lot of Slitting Saw Blades Gear Cutter for Mill j

HSS milling hobbling gear cutting cuter no 5 1P 21 to 25 Teeth used

THURSTON CUTTER (steel) 39ZA-360 (7.500 x .284) NEW

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies