US $705.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Model | CS-HTS-002 |

| product ID | 1759 | ||

| Country/Region of Manufacture | China |

Directions

Similar products from Other

Klein Tools Ironworker's High-Leverage Pliers, 9in (KLND20009ST)

NEW Speedway ST400 Electric Series 75' Cable Drain/pipe Cleaning Product Machine

Champion Aerospace Replacement Bearing Kit (K3320)

Rotozip revolution roto-zip roto zip

Craftsmaan tool kit with extras

APC Filtration Micro Filters, Windsor Sensor, 25 Filters (APC JAN-IVF155)

Proto 12-Piece Convertible Retaining Ring Pliers Set (PTO360B)

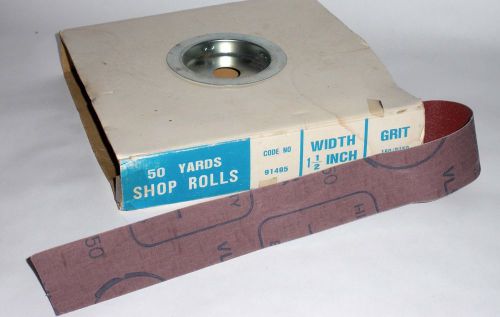

GRIT 1 1/2 ” WIDE X 150 46 YARD Sandpaper Roll

Milescraft 14000713 Saw Guide for Circular and Jig Saws1

New Mug Cup Heat Press Epson Printer Sublimation Kit, Transfer Paper Package

Channellock 85 Fence-Tool Pliers, 10" Tool Length, 3/4" Jaw Length (CHN85BULK)

New Plate Heat Press Epson Printer Sublimation Kit, Transfer Paper Package

ARO 47300-1 Electric Torque Controller w/Low torque Screwdriver Parts/Repair

Proto Side Cutting Needle Nose Pliers (PTO226G)

New T-shirt Heat Press Epson Printer Sublimation Kit, Transfer Paper Package

Weiler Dualife ST-8 Twist Knot Wire Wheel, 8"dia, .023 Wire (WEI08155)

ATLAS COPCO ETD ST31-05-I60 TENSOR ST ELECTRICAL SCREWDRIVER

Pneumatic Dual-axis Metal Letter Angle Bending Machine for LED Letter Signs

Proto Forcing Screw, 3/4" (PTO4225S)

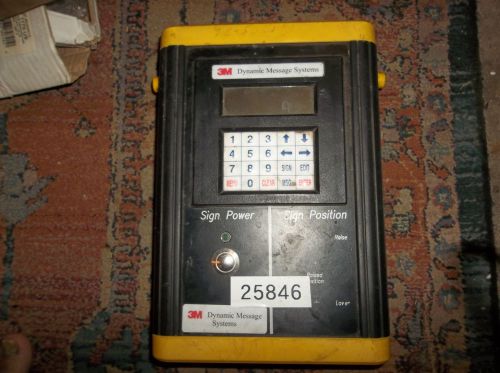

3M DYNAMIC MESSAGE SYSTEMS BOARD COMPUTER CONTROL

People who viewed this item also vieved

Hackett 10 ton chain blocks hoist block and tackle

2x Layher Basisstrebe 1324.180 Strebe 1,8m Rollgerust Gerust Fahrgerust Bau

Gesipa Powerbird 14.4V Cordless Riveting Tool Industrial Assembly, New In Box

Fossil Sea Floor Decorative Concrete Rubber Stamp Tool Mat 9F17

Illuminator Self Powered 4-in-1 FM Radio / Alarm / 3 White focused LED flashl...

SASE Med to Hard Concrete 16 Gret 502602QCS Diamond Tooling

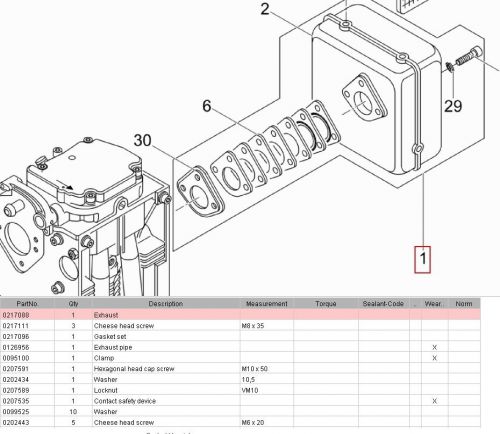

NIB Genuine Wacker Neuson Muffler 0217088, 217088 DPU-6055 FREE SHIPPING

Brand New! Eaton Compressor! 125HP 3PH Rotary Screw Air Compressor PKG

REMINGTON 482 PISTON AND BUFFER Kit 078613 PISTON & TA4083 BUFFER 102620

HEIN-4022-Heininger 4022 HitchMate NetWerks BedBag

Greenlee Mod. 849 1/2"-2" PVC Conduit heaterwith 50 Ft. 20 amp extension cord

MIG Welder Welding Machine Wire Drive Motor Feed Feeder Roller 0.6 12V amp New

Furnace Generator Transfer Switch One Circuit 15 Amp 120V Manual EZ DIY Install

Bosch 14 Amp SDS-max Demolition Hammer 11316EVS NEW

Collomix MK160HF Steel Hexafix Quick Connect Heavy Duty Concrete Stirring

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies