US $170

Directions

Similar products from Various Tool Bits

Vintage Chicago-Latrobe Set #6 Interchangeable Counterbore Set Made in USA

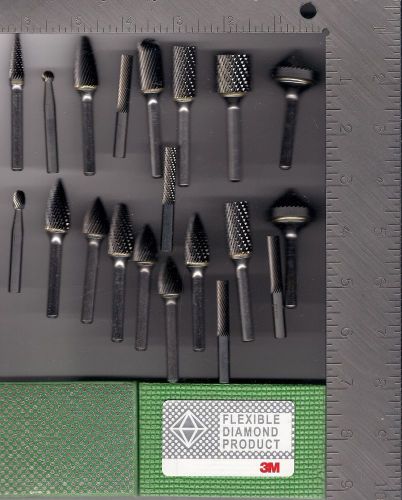

20 Carbide Burr Bits +1- 3M Flex Diamond Pad Green

Severance CK-82-1403 6 Flute HSS 5/8" Countersink 3/8" shank Drill or CNC USA

Hougen 12218 M231010-3906 9/16" Rotabroach 2" DOC

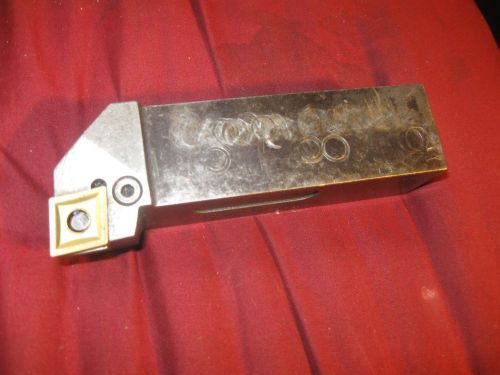

1 1/2 x 1 1/2 insert tool lathe ,boring mill

CARBIDE TOOL BIT BOX LOT, 1/2, 5/16 & 1/4", Carboloy, Super Morse, Others, NR!

Borite C7L-6 Boring Bit milling lathe -NOS-

Borite 1206-745 Boring bit milling lathe -NOS-

5 Pcs Brand New Carbide PCB Engraving Bit CNC Router Tool 10°0.1mm Hot Sale

LOT OF 5 NEW UNUSED HSS 1/4" CUTTING TOOL BITS 4 MACHINIST METAL TURNING LATHE

Super Alloy T15 Thread Cutter 1/4" Mini Lathe Tool Bit Machinist Sherline Unimat

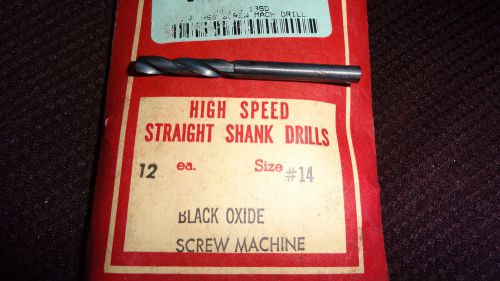

Drill bits #14 black oxide screw machine -qty. 12

Melin countersink 3/16ths x 120 deg.4F

Machine tooling lot #5 3/8th ball mills

Machine tooling C5 collet lot #3

Machine tooling lot #6 5/32 end mills

People who viewed this item also vieved

DDJNR 24 4D - Sandvik Coromant Tool Holder

CNMG 432RP KCM25 KENNAMETAL CARBIDE INSERT

CNMG 432-MF4 TM4000 SECO CARBIDE INSERT

SGS #38067 SER 1 * 1/2 .060 CORNER RADIUS ENDMILL **NEW IN PACKAGE** 1 PC

Union Butterfeild Chucking Reamers SIZE .1495, Lot Of 4 SS -S F LOT 45

Union Butterfeild Chucking Reamers SIZE .1698, Lot Of 4 SS -S F LOT 38

LOT OF 10 KYOCERA CERATIP CNGN120412 CNG433 KS500 CERAMIC INSERTS

![KENNAMETAL Ceramic Inserts CNGX453T0820 Qty 10 [205]](/_content/items/images/55/4696155/001.jpg)

KENNAMETAL Ceramic Inserts CNGX453T0820 Qty 10 [205]

DUNKES Pneumatic Press DFX 05 Bench Type w/Base Clamping Force 10Kn, No-Reserve

Greenlee Hydraulic Knockout Driver~1731 w/Punches & Dies for 1/2,3/4 &1' Conduit

Hougen HMD150 Low Profile Portable Magnetic Drill (115V)

Hougen HMD927S Power Feed Magnetic Drill with Swivel Base (115V)

B&S 4" x 3/16" x 1" STAGGERED MILLING CUTTER HORIZONTAL SLOT SLOTTING BLADE

NATIONAL 4" x 5/16" x 1-1/4" STAGGERED MILLING CUTTER HORIZONTAL SLOT BLADE

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies