US $1500

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Type | Laser |

| Brand | Unbranded | ||

| MPN | 134121 | ||

| Intended Use/Discipline | Anesthesiology | ||

| UPC | 748497571817 |

Directions

Similar products from Other Medical Equipment

BAPS Biomechaical Ankle Platform System

Stryker SDC3 HD Digital Capture Unit Info Management System

BodyMed Premium Headrest Paper Sheets, Case of 1,000

BodyMed® Disposable Exam Gowns – Disposable Medical Gowns for Adults – Case of

White Dental Gauze/Cotton Pad Sponge Dispenser Holder Spring Loaded 105*55*55MM

10 Dental Orthodontic Interproximal Enamel Reduction IPR Automatic Strips 25 HD

Multiple Makes of Autoclave Repair Parts Lot of Misc Service Parts

DU-O-VAC Oxygen Regulator 3-100 W.T. Farley

2005 Palomar QYag5 Tattoo removal system

Portable Mobile Dental Delivery Unit Cart Standard Trolley Fiber Optic Handpiece

5 Pack Dental Orthodontic Close Spring Coil Niti Anterior Teeth Tooth Torque

Olympus MAJ-1916 CV Interface Converter, NEW IN BOX!!!

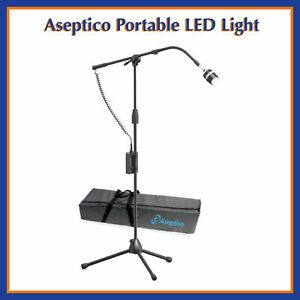

Aseptico Portable LED Light - ALU-40LED

GE MRI Devices Neurovascular Array 1.5T Coil Model 2225476-2/100137

Gerson Nuisance Dust Mask 50/Box 1501

Dental Interproximal Reduction Strip IPR System Orthodontic Hand Use Kit 1PK

PK Test Tubes, 30ml - Bakelite Screw Cap with Rubber Liner - Borosilicate 12

Eyes Artificial Eyes 25 Set Prosthetic Eyes BEST QUALITY Free Shipping

Synoptophore Stereoscope Strabismus Free Shipping

Capsl Filling Machine 100 hole Manual ''0'' Size WITH FREE SHIPPING

People who viewed this item also vieved

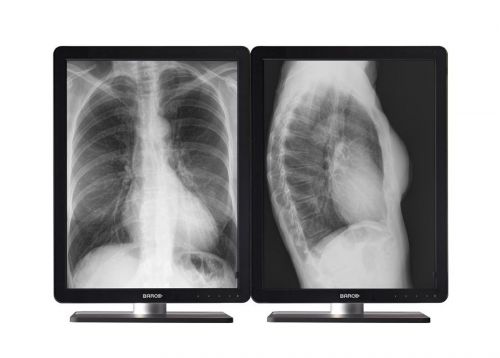

New Pair (x2) Barco Coronis MDCG-3221 LED 3MP Grayscale Medical Monitors

GENERAL ELECTRIC AMX3 MODEL 46-217900-G2

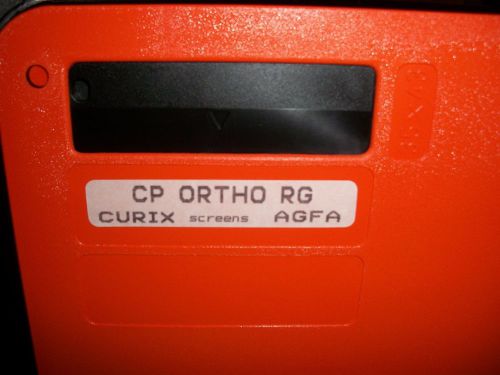

AGFA CP Ortho RG Fine Curix Screen X-Ray Developing Cassette 35X43

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies