US $39.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

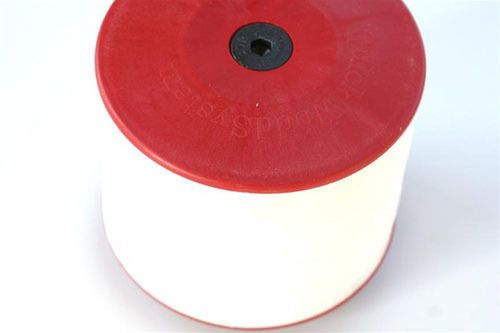

Manufacturer | Parlec Co. |

| Holder Type | END MILL | ||

| MPN | H63E50SF315 | ||

| Toolholding Part Type | HSK Tool Holders |

Directions

Similar products from Other Tool Retention Items

CENTAUR REDUCTION SLEEVES HYDRAULIC TOOL HOLDERS 3/4-0.1562

CENTAUR REDUCTION SLEEVES HYDRAULIC TOOL HOLDERS 1-1/4 -8MM

CENTAUR REDUCTION SLEEVES HYDRAULIC TOOL HOLDER 32MM-25MM

Lyndex collet holders - 1" shanks - 2 pieces

Amec 2111t- 1000 1t-a 1 " ss indexable spade drill holder w/spade

KENNAMETAL TOOL HOLDER 1 1/4 TALL 1" WIDE 5 1/4 LONG UNKNOWN PART #

UNKNOWN BRAND TOOL HOLDER 1 1/4 TALL 1" WIDE 5 1/4 LONG UNKNOWN PART #

CARBOLOY TOOL HOLDER 1 1/4 TALL 1" WIDE 5 1/4 LONG UNKNOWN PART #

KENNAMETAL TOOL HOLDER 1 1/4 TALL 1 1/16 WIDE 5 1/4 LONG UNKNOWN PART #

Turning tool holder mtrnr-164d brand new with inserts

WAUKESHA SERIES C 1-7/16 SPADE DRILL HOLDER 17" FLUTE LENGTH 24.5 OAL #4MT SHANK

TPG BORING TOOL WITH CARBIDE INSERT

KENNAMETAL FACING TOOL WITH CARBIDE INSERT

MACHINIST LATHE MILL Small Starrett Pin Vise

MARTIN 602A SINGLE OPEN LOW-PROFILE CHECK NUT WRENCH 9/16 INCH. MADE IN USA

Smith Tool Smith Lock 3717-SST

NEW SANDVIK 391.38A-2-C09A Fine Boring Tool Insert Cartridge

Komet UB8603120 Dia. 2.028", Length 4.00"

Komet KUB ABS 50 V72760 Insert Drill

Sandvik PTFNL 200A-22 (3 Total with inserts)

People who viewed this item also vieved

PARLEC NUMERFLOAT CAT 50 TG100 COLLET FLOATING REAMER HOLDER CHUCK LOT C11240

LYNDEX BT50 SHELL / FACEMILL HOLDER 1-1/2" PILOT BT 50 FACE MILL LOT C11607

Armstrong Boring Bar # 07A 1/2' Bar 3/16" bit, Lathe Milling Machine.

Armstrong Boring Bars, Lathe, Milling Machine. 84-371, BC-30 HS, BC-15HS, BC-5HS

10 SECO inserts XOMX 180608R-M10 F40M NEW!!

SANDIK 2" INDEXABLE FACE MILL 3/4" BORE + NEW SOLID CARBIDE INSERTS

2-3 Morse Taper Adapter Machinist Tool Metal Lathe Southbend Atlas Cradtsman Jet

228080 - Dodge 228080 K35 Tl Hub 228080 Thrust Plate Hub Bushing

NEW DODGE TAPER LOCK BUSHING 119119 2517 X 1 11/16" 2517X11/16

Metaltech, Pull Stud, BT40, 45 degrees, Thread M16, Length 60mm, Shaf 10mm, New

New CAT40 1.0" Shell Mill Arbor

Llambrich Keyless Drill Chuck, 1/8-5/8" Capacity, JK-16 J33 | (27C)

LOT OF APPROX. 150 SA200 SERIES TOOLHOLDERS

Yuasa 740-305 Quick Change Tool Holder

4" Spindle with 3/4" bore for attachment to your motor pin

PRECISE PCF 310 High Frequency Spindle FREQUENCY CONVERTER SOLID STATE

K.O. Knockout Mandrel machinist Tool Model # M101 / 16 3/4 x 1 9/16 OAL w/ case

Industrial Hole Saw Arbor Mandrel 3/8" Shank Fits 1-1/4"-6" Saws Forney #20758

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies