US $49

Directions

Similar products from Jobber Drills

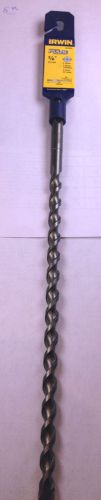

3 PCS Irwin 5/16 x 6 x 4 Masonry SDS Plus Shank #322022 Carbide Drill Bit

GUHRING 1/2" (12.700mm)Parabolic Flute Jobber Length 6" (131mm) HSS Drill #549

![T&O M78 Cobalt Jobbers Length Twist Drills Right P M35 Straight [pak 6]](/_content/items/images/5/5145405/001.jpg)

T&O M78 Cobalt Jobbers Length Twist Drills Right P M35 Straight [pak 6]

JOBBERS DRILLS MISC MIX .157 TO .216---20 PCS

Cleveland C71073 - 2001G LTR-C HS Jobber Drills Box of 11

1 PCS Irwin 5/8 x 8x 6 Masonry SDS Plus Shank #322042 Drill Carbide Bit

2 PCS Irwin 1/2 x 8 x 4 Masonry SDS Plus Shank #322031 Fast Cutting Carbide Bit

1 PCS Irwin 3/8 x 12 x 10 Masonry SDS Plus Shank #322026 Carbide Drill Bit

1 PCS Irwin 7/8 x 12 x 10 Masonry SDS Plus Shank #322052 Carbide Drill Bit

1 PCS Irwin 3/4" x 12 x 10 Masonry SDS Plus Shank #322048 Carbide Drill Bit

1 PCS Irwin 3/4" x 8 x 6 Masonry SDS Plus Shank #322047 Carbide Drill Bit

Huot jobber metal drill index set 115 bits -incomplete

Precision Twist Drill 11/16 Inch, 118 Degree Point Angle, Oxide Coated

PTD BLK & SHK S&D 45/64" HS DRILL W/1/2" STRAIGHT SHANK 6-1/4 LONG

4 Lawson Products 10884, 19/64 HSS, Regency Mechanics Length Drill Bits

3 Lawson Products 10897, 1/2 " HSS, Regency Mechanics Length Drill Bits

Champion 160C General Purpose HSS 705 series 1-60 Wire Gauge Drill Set 60-Piece

Champion 705SP-1/4 Heavy Duty Jobber Twist Drill 135 Degree Split Point 12-pack

Champion TWISTER-XL28 Brute Platinum HSS Twister Mechanics Length Drill Bit S...

People who viewed this item also vieved

NEW SURPLUS CLEVELAND CLE-FORGE USA 25/32" S/SHANK COOLANT TWIST DRILL .7812"

LAST ONE! NEW SURPLUS MOHAWK USA STRAIGHT SHANK 20.5mm COOLANT TWIST DRILL .8070

NEW SGS 3 FLUTES 16MM SOLID CARBIDE STEP DRILL FREE SHIPPING!!!

USED TRW CONVOLUTE EXTENDED LENGTH S/SHANK TWIST DRILL 21/64" PARABOLIC .3281"

T Cleforge DRILL BIT 25/32" taper length CLE-FORGE USA model 225716 drilling

Precision Twist 9/32" Taper Length Drill 118 Deg HSS Helix L 6 1/4" Flute 3 7/8

Used 3/4-32 Threading Tap, 3/4" - 32 Thread, GREENFIELD, # 04A

Used 11/16-24 Threading Tap, 11/16" - 24 Thread, SWANSON, # 03A

Used 5/8-20 Threading Tap, 5/8" - 20 Thread, , # 02A

SCREW MACHINE LENGTH DRILL BIT, 2 FL, 2"x 5-5/8"x 8- 1/2 OAL, Spiral, HSS, /HF2/

Cleveland C-15/64 Cobalt Screw Machine Drill

Champion 1705C-21 Cobalt Screw Machine Drill

5 PCS D 1,6 mm SOLID CARBIDE DRILL PCB.

5 PCS D 1,7 mm SOLID CARBIDE DRILL PCB.

10 PCS D 1,1 mm SOLID CARBIDE DRILL in the protective coating.

Illinois / Eclipse 23/32" EDP 11696 Straight Shank Taper HS Super-Tem XX Drill

USED MORSE USA TAPER SHANK COBALT 43/64" TWIST DRILL #3MT .6718"

Omark industires drill and c'sink, L-301N14-38 rev. K

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies