US $9.95

| Condition: |

New other (see details): A new, unused item with absolutely no signs of wear. The item may be missing the original packaging,

or in the original packaging but not sealed. The item may be a factory second or a new, unused item with defects. See the seller’s listing for full details and description of any imperfections.

...

|

Brand | Bio-Cide |

| Country/Region of Manufacture | United States |

Directions

Similar products from Poultry

6 Cream, Gold and/or Silver Appenzeller Spitzhauben Hatching Eggs!!

9 (+ extras) Fresh American Serama eggs - Tiny!!

sav-a-chick electrolyte and vitamins, 3 pack makes 3 gallons

(45) Water Nipple Drinker Chicken Feeder Poultry Duck Hen Screw In Style

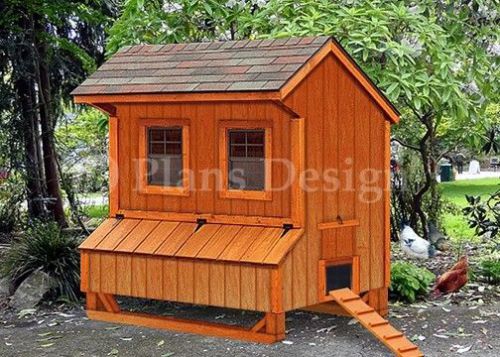

Backyard Hen House / Chicken Coop Plans Easy DIY #90504G, Free Chicken Run Plans

10' x 12' Reverse Gable Shed Plans,Free Material List #D1012G

5' x 6' Chicken Coop Plans, Saltbox Style Design #E90506S, Special Price $12.95

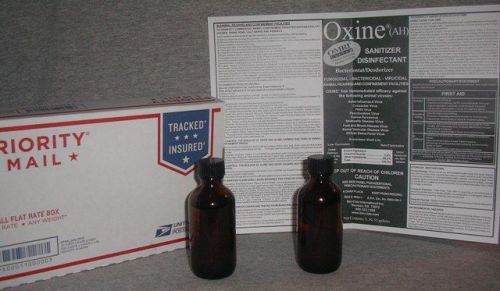

Oxine Sanitizer and Disinfectant (2) 1.6 fl oz bottles, Great for Poultry

24 fingers plucker for chicken, goose, duck or turkey. LIMITTED version

15 fingers plucker for chicken, goose, duck or turkey. LIMITTED version

10 fingers plucker for chicken, goose, duck or turkey. Cheapest version

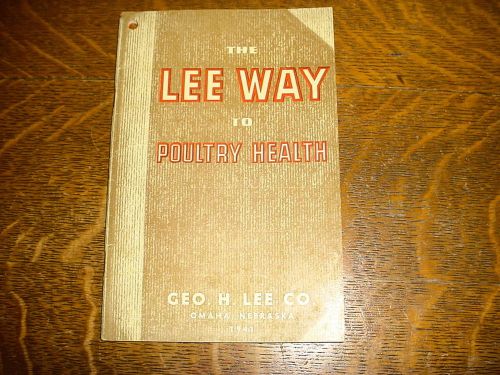

The LEE WAY to Poultry Health 1941 publication

![ValueTek HPS High Pressure Sodium Poultry / GH fixture 150 watt [hub#14332011]](/_content/items/images/1/3395001/001.jpg)

ValueTek HPS High Pressure Sodium Poultry / GH fixture 150 watt [hub#14332011]

Vintage Chicken Tube Feeder Lipman Poultry Feeds Painted on Front Dark Blue

New Anti Bird Netting 50'X50' Net Netting Aviary Game Poultry Bird 1"x1" Mesh

SOLWAY EGG COLLECTION BASKET 200 COUNT

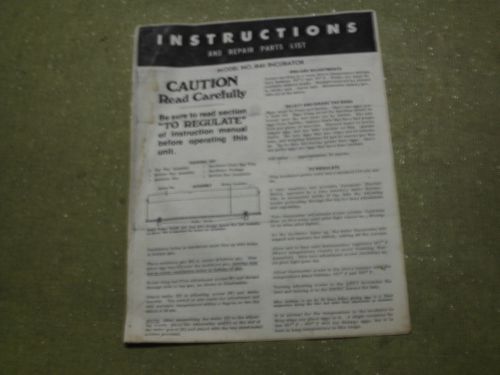

vintage Brower Egg Incubator Model 846 Manual { MANUAL ONLY }

12 Blue isbar chicken hatching eggs NPIP

People who viewed this item also vieved

Sprayer Nozzle Only fits 16 oz or 32 oz Bottles SALE Package of 6

Prima MARC Syringe 2 ml Replacement Barrel and O Ring SALE

6 BAR HVY DUTY 2 IN O.D. JOHN DEERE GATE 16 FT

6 BAR ECONOMY JOHN DEERE GATE 4 FT

Vintage Surge Babson Brother Stainless Steel Milker

Surge Milking Machine Milker Stainless Steel Bucket

2pcs Nylon Honey Gate Valve Honey Extractor Honey Tap Beekeeping Bottling Tools

Professional 3 Frame SS Honey Extractor, Beekeeper Supply, Beehive Processing

Medline Industries DYNJP2410 Half Surgical Drape, 40" x 58" Pack of 20

Multi- Combo (Testodione,Calphos-D,Gallo-K) one of each.

Parnell Bottle Mount 1ML Fixed Dosage Vaccinator Dairy Beef GonaBreed NEW

Parnell Bottle Mount 2ML Fixed Dosage Vaccinator Dairy Beef EstroPLAN NEW

VINTAGE STEWART 21 SHEEP COW,HORSE ANIMAL CLIPPERS

Giantex 320w Electronic Shearing Clipper Sheep/goat Animal Shear Farm Supplies

Livestock Animal Silicon Gastric Feeding Tube Bullet Point Cap Luer 6 FR

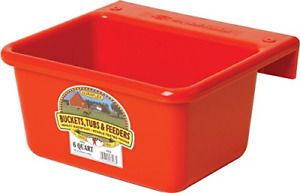

Little Giant Red Mini Feeder MF6-RED

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies