US $320

| Condition | Used

:

An item that has been used previously. The item may have some signs of cosmetic wear, but is fully operational and functions as intended. This item may be a floor model or store return that has been used. See the seller’s listing for full details and description of any imperfections.

|

| Seller Notes | “No License, key code or password to run PAM-RTM software!” |

Directions

Similar products from Software Programs for Metalworking

GRECO CNC MINIFILE SYSTEM SOFTWARE FDS-200 V04.05

Bend Tech Sheet Metal Layout & Design Software BTSM

Ucancam V9 3D CNC Engraver / Router Engraving Software can do Rhinestone ~G Code

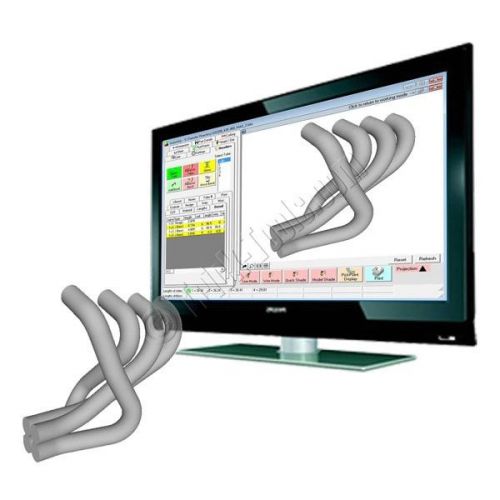

Bend Tech HD Header Design Software Tube Pipe Bending

Staveley 232 Sonic Ultrascope Metal Flaw Detector ! WOW !

Bend Tech Super SE Software Tube Bending Pipe Bender

Bobcad v25 & 48v 12.5a Power Supply (International Shipping Welcome)

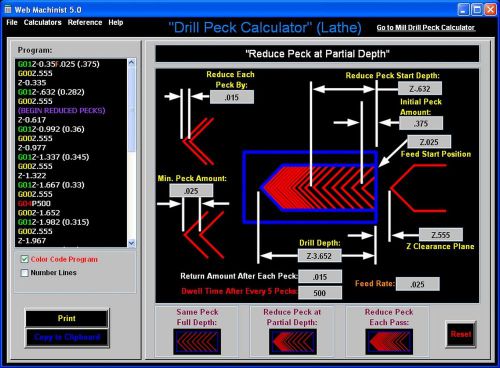

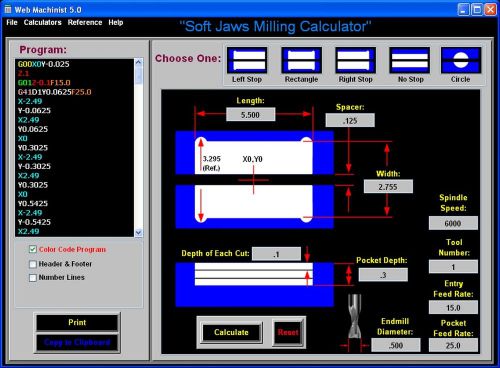

CNC Machinist Software Spot Drill Haas Drill Cad Cam Carbide Endmill Carbide 90

CNC Machinist Software Step Drill Bore Boring Tool Mill Lathe Carbide Insert Bar

Renishaw Okuma OSP 100/200 M/C Contact Tool Settng CD Software A-4016-1039

CNC Machinist Software Hobby Lathe Mill Home Center Finder Edge Centre Haas Cad

MACHINIST CALC PRO - CD VERSION for WINDOWS- CALCULATED INDUSTRIES

BobCAD-CAM v26 2D & 3D CAD/CAM Full Software, Never Installed, 32- & 64-Bit

LIGHT MACHINES PROLIGHT MACHINING CENTER CNC MILL

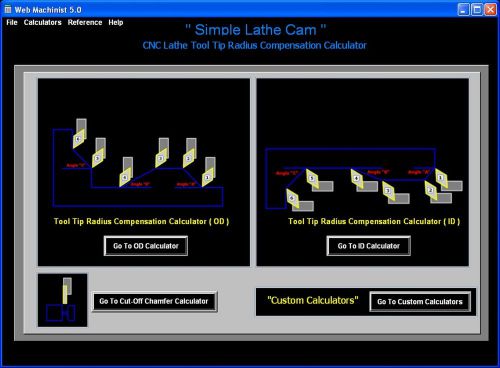

CNC Lathe Mill Software Haas Mori Seiki Okuma Bridgeport Kitamura Mazak Machine

CNC Machining Software ER16 Collet 19/64 5/16 21/64 11/32 23/64 3/8 25/64 13/32

CNC Machinist Software Haas Hobby Mill Lathe Rougher Cad Cam Starrett Indicator

CNC Machinist Software Hobby Starrett Fowler Interapid Indicator Cad Cam Cad/Cam

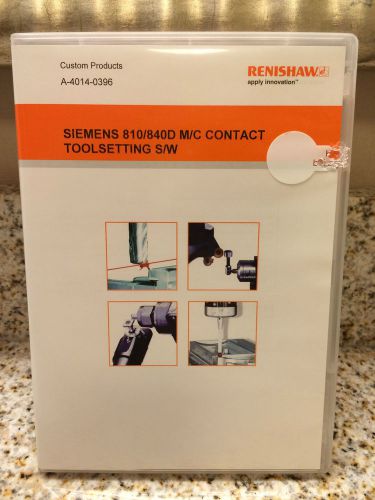

RENISHAW A-4014-0396 SIEMENS 810/840D M/C CONTACT TOOL SETTING SOFTWARE *NEW*

People who viewed this item also vieved

(1) Tube Form Vise & Ram Forming Machine - Type RF - Used - AM6449

TECLOCK DIAL INDICATOR & MAGNETIC BASE STAND

Starrett 486-1 1" blade micrometer USA

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies