US $5900

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Product Type | Equipment |

Directions

Similar products from Equipment

CASE IH 770 DEEP TILL OFF-SET DISC. READY TO LOAD!!!

Timber Measurements - A Practical Guide for Working in the Woods

Log Rules and Other Useful Information - estimating lumber yields in the woods

Antique Mc Cormick Haybine Plataform

ECHO BEAR CAT HONDA 670cc SC5670B (25524) 5" CHIPPER SHREDDER TRAILER SUFFOLK NY

Ford F 700 Forestry Bucket Boom chipper Truck Dump ARBORTECH Diesel

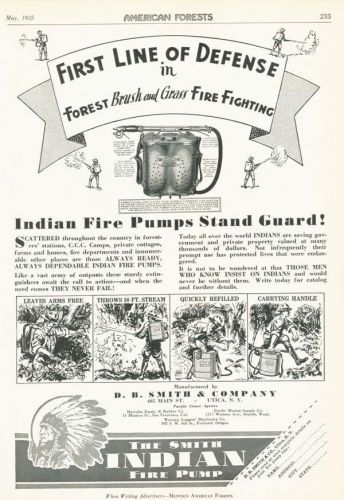

1935 DB SMITH FIRE PUMP BRUSH FOREST SERVICE RANGER FIRE FIGHTING EQUIPMENT A

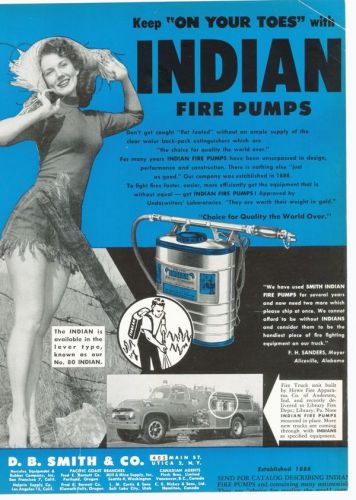

1947 DB SMITH INDIAN FIRE PUMP TRUCK FH SANDERS MAYOR WOOD FOREST NOZZLE SEXY

1952 CHAMPION TRUCK LOGGING US FOREST SERVICE TREE PLANTER DOZER SMOKEY BEAR

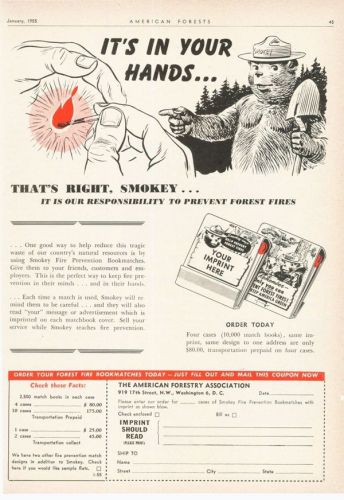

1955 AMERICAN FOREST SERVICE FIRE MATCHS LUMBER TREE SMOKEY THE BEAR CAMPAIGN

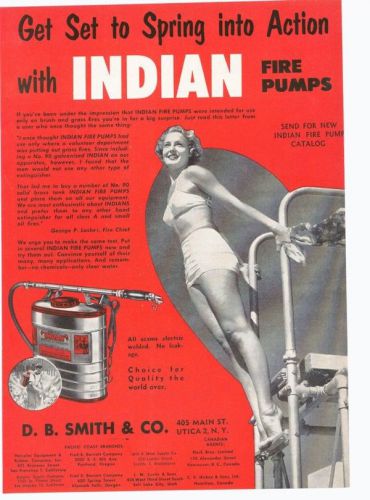

1955 INDIAN FIRE PUMP LASHER FIGHTING SEXY SWIMSUIT PINUP FOREST SERVICE AD

1956 INDIAN FIRE FIGHTING AD WHITNEY HAWLEY SEXY PINUP UTICA FOREST SERVICE

1956 INDIAN FIRE PUMP EXTINGUISHER AUBREY ROBINSON SEXY PINUP US FOREST SERVI

Homebuilt 3 Point Hitch Tractor Utility Basket

7x12 double motorcycle enclosed trailer w harley davidson decals blk ORANGE 2014

ALUMA 8112 aluminum trailer double atv with side load ramps and tailgate NEW

8x16 Enclosed Motorcycle Cargo Trailer carhauler trailer new 8.5 x16 7k sport

People who viewed this item also vieved

1 NEW GENUINE OEM KUBOTA FUEL SHUTOFF SOLENOID PART # 1A021-60017

1 NEW GENUINE OEM KUBOTA OIL PUMP PART # 15471-35013

CTA High Pressure Spring Loaded Quick-Disconnect Lock On Grease Coupler # 7790

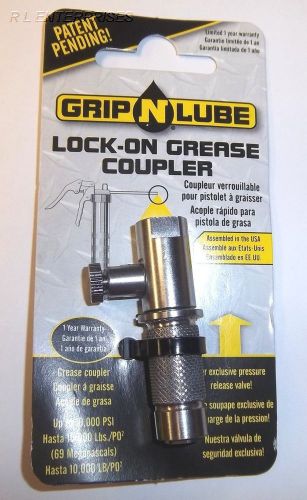

Grip-N-Lube Lock-On Grease Coupler with Pressure Release Valve # 944IRV

NEW SHEFFIELD ENGLAND BARB WIRE FENCE FENCING PLIERS STRETCHER TOOL NO 51

1 NEW GENUINE OEM KUBOTA ELECTRIC FUEL PUMP PART # RC601-51352

Curly Koa From Hawaii Veneer For Inlay And Jewelry Box Making 22 Pcs@23"x2-5x1/8

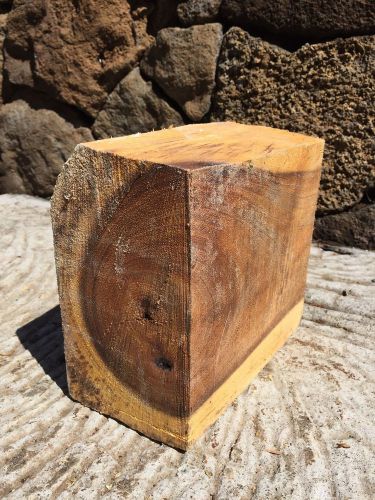

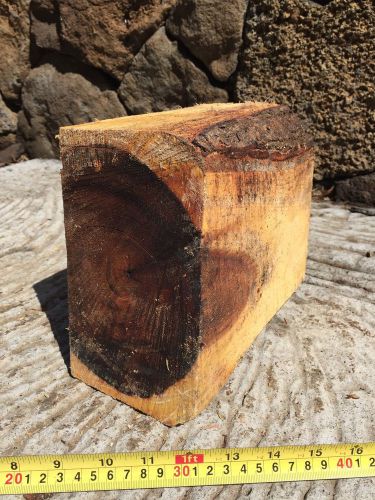

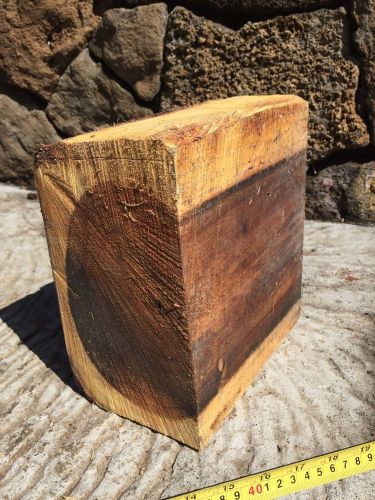

Hawaiian Monkey Pod Bowl Blank 9"x8"x4.5" Reclaimed Tropical Wood Turning

Hawaiian Monkeypod Bowl Blank 8"x7"x4" Reclaimed Tropical Wood

Monkey Pod Bowl Blank From Hawaii 8"x8.5"x5" Reclaimed Tropical Wood

KUBOTA RTV ATV SIDE BY SIDE DIESEL 900 DUMPING YARD BUGGY FARM RANCH

Antique Monitor L Vaneless Windmill Parts

EATON MODEL 6 HYDROSTATIC TRANMISSION MODEL 600-004 CCW ROTATION

Warren Axe & Tool Co. - Tree Felling Iron Wedge-----Old Tool

KOHLER LOMBARDINI DIESEL ENGINE AIR FILTER PART# ED0021753060-S

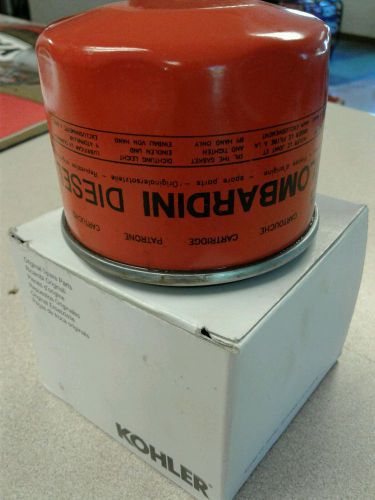

KOHLER LOMBARDINI DIESEL ENGINE OIL FILTER PART# ED0021751070-S # ED0021752830-S

New MINNEAPOLIS MOLINE Tractors Wall Clock 12 Vintage Tractors Wheel Dial Clock

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies