US $695.00

Directions

Similar products from Rotating Tables

COLLIS 68056 50NMTB 100 EMH N9 TOOL HOLDER

ADJUSTABLE TAILSTOCK (3900-2409) - MADE IN TAIWAN

CLEAN! TROYKE 15" HORIZONTAL / VERTICAL ROTARY TABLE - #U-15

Devlieg 30" x 30" Power Rotary Table, S/N 99033, Used, WARRANTY

industrail tooling chemical engineers hadbook

TROYKE 30" FULL 4 AXIS CNC VERT-HORZ MOUNT ROTARY TABLE WITH FANUC 20M SERVO

Yuasa 16" Vertical Horizontal Rotary Table NICE Condition

New Mini Rotary Table 3" / 75mm Horizontal & Vertical Model - Milling Machine

Nikken Fourth Axis Rotary Table Indexer

6'' Horizontal/Vertical Precision Rotary Table, #5817-4006

12" High Performance Precision 4th & 5th Axis CNC Tilting Rotary Table USA Used

8'' Horizontal/Vertical Precision Rotary Table, #5817-4008

Dividing Plate for 6'' Horizontal/Vertical Precision Rotary Table, #5817-5006

12.5" Horizontal Precision Rotary Table - Machinist Tool -Chicago Pick-up Only

SEMPRESS HOLLAND 14" DIAMETER PNEUMATIC INDEXING TABLE 2118002 1182838

Troyke T5C 1 A (4) Spindle Head CNC 4th Axis Rotary Table, 5C Collet Chuck drive

Bridgeport 15 inch rotary table

EXCELLENT!! YUASA 550-008 VERTICAL HORIZONTAL ROTARY TABLE / INDEXING SPACER

EXCELLENT!! YUASA 8" VERTICAL HORIZONTAL INDEXING SUPER SPACER # 550-008

People who viewed this item also vieved

Riten L-3 Engine Lathe Live Center W/ #3 Morse Taper

Bull-Nose Live Center; #2 Morse Shank (CTAM 9614)

ROYAL 10909 Pipe And Bull Head Live Center-Taper:5 MT

Suburban Sine Plate Tool Angle Sp-136 6x3x2 Machinist Inspection

Suburban Tool INC.Taft Peirce sine bar. Very nice in wood case Item 6

Suburban Precision Angle Plate

C-5 Collect Milling Fixture - C-5 Collect Milling Vise Vertical Horizontal mount

7/8 5C Collets Type: round Collet Size (Inch):.-875

NEW TSD AF118 COLLET 7/16" ROUND STK 4565

Vtg. J.H. Williams C Clamp No.Cc-404-4", Deep Throat 2-3/4" CC-404

Knu-Vise V-200 Used Verticle Clamps (QTY 2) Aircraft Tool

Chas Parker Vise No. 202 Replacement Part MAIN NUT Lead Screw Nut

Heinrich pneumatic 4" vise w/ micro adj ratchet

Machinist Or Toolmakers Hardened Vise (1 1/2" Capacity)

Toolmex-Tmx 12.0" 6-Jaw "SET-TRU" Forged Steel Body Lathe Chuck, 0.0006" T.I.R

Toolmex-Tmx 16.0" 3-Jaw "SET-TRU" Semi-Steel Body Lathe Chuck, 0.0006" T.I.R

metal spinning mandrel,metal spinning form

ATS Collet Chuck / Spindle Nose 42060A - D07 , A6 - S20H BB

Leathercraft Kit-Dark Brown Journal

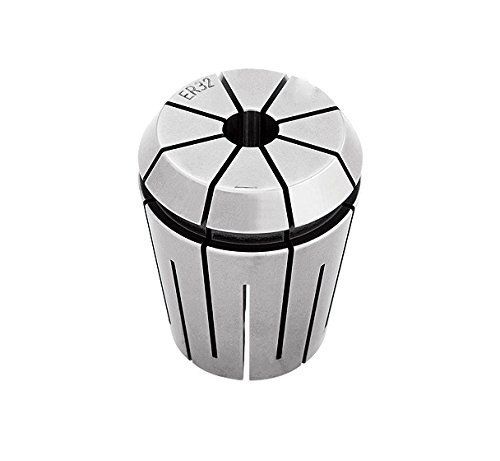

Pro Series HHIP Pro Series by HHIP 3900-5550 ER-32 Coolant Thru Spring Collet,

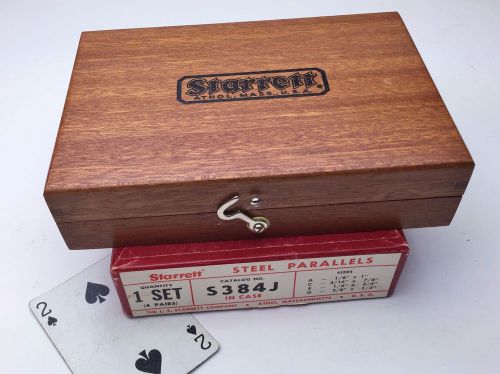

NOS Starrett 6" Steel Parallels Set in Case 4 pairs, 8pcs total S384J NEW & MINT

JEWERLY POUNDING BLOCK SOLID STEEL 5Lbs 3-1/2" X 3-1/2" x 1-1/2" NOT POLISH

Uncoated 2 - 3 - 4 Block Set <Z19>

48"x40" Rolling Steel Assembly Set Up Work Table 1/4" Top 2"x2" Legs W/ Shelf

JERGENS Serrated Master Key 1-11/16" x 1" x 1/2" x 1/2" x 3/8" hole WORK-HOLDING

Huron KT8 EH Chuck Jaws - Lot of (3)

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies