US $96000

Directions

Similar products from Other Tools for Printing Businesses

AB DICK 9850 HEIDELBERG HP INDIGO RYOBI HAMADA OFFSET PRINTING PRESS - S756

All Purpose Manual Table Top Paper Cutter

(3) three brand new boxes of presstek DPM ait filters look save $$$$ here

DPM plate material cartridge keep a spare on hand look save

1 quart container dispenser for fluids pressurized self filling

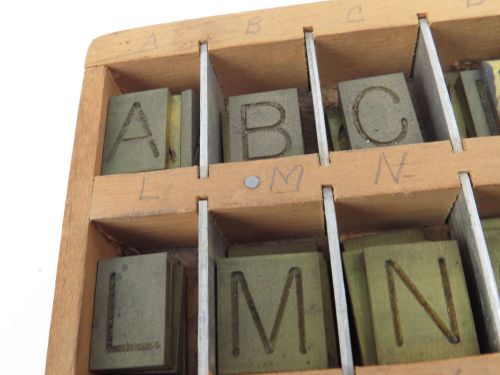

lot of assorted block type and some cuts with metal type look collectable

tall plunger can for press wash and other chemicals look save

Short plunger can for press wash and other chemicals look save

metal type composing stick look hard to find item

Heidelberg QMDI four color great clean unit

Vintage printers printing California wooden type job case for type fonts - N/R

Desktop UV Coating Machine 18'' UV Varnish Coater

HP Indigo Bobbin Wire w/ Dumper MKT-1106-06 10 pieces new OEM

TRIO 3022 - 51" ROTARY PAPER CUTTER TRIMMER - FREE SHIPPING

Speed-O-Print print duplicating template Number 115

Heidelburg GTO Ink Fountain Liner's

Hamada Printing Press New & Used Parts

JETWEB Inline Finishing Syetems D-74747

Tec Lighting UV Coater Model TRUVF21D

People who viewed this item also vieved

New In Box PSI Cyan Toner Cartridge LM3640/3655 Digital Envelope Press 18903

M0001556, IBIS, PLATE SPRING, 7100003571 (NEW)

53F1818, IBM 4000 Double Sided Belt, Tractor Drive, 7100009708 (NEW)

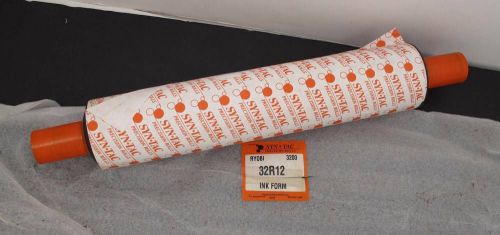

Ryobi Syn-tac 3200 32R12 Ink Form Roller

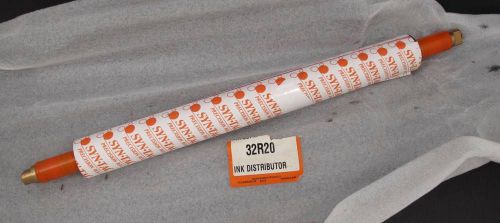

Ryobi Syn-tac 3200 32R20 Ink Distributor Roller

Ryobi Syn-tac 3200 32R33 Ink Ductor Roller

RNDP932-500-390, Meaden, FILE HOLE DIE, 9/32, .500 X .577, PUNCH FILE (NEW)

VTG Letterpress Alphabet 1/2" Number Brass Engraving Plate Set Printing Block 2

**Rotec Die Cutter** 8-Up Wallet, Kiss Cut , Rounded Corners!!

Morgans & Wilcox M&W Job Press Locks Letterpress Furniture Quoins Set Printing

Letterpress Press Chase - 10 x 15 Unmarked C&P? Maybe?

Handheld 2" x 2" Passport Photo ID Die Cutter Punch

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies