US $16000

Directions

Similar products from Filtering Machinery

SANITARY COLUMN VESSEL SWAGELOK 24" UNUSUAL STAINLESS GAS PNEUMATIC NEW $399

Vickers 941412 Hydraulic Filter Kit / NEW

PALL ULTIPOR N66 FILTER MCY1001NAEH 0.2 um

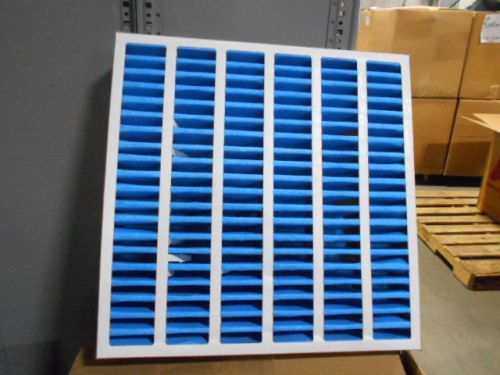

AMERICAN AIR FILTER 170102863 **NEW NO BOX**

DONALDSON 8PP2040000 **NEW NO BOX**

Millipore Wafergard-40 WGGL40S01, Cartridge Filter , 0.2um, NIB

Water Filtration Skid - Vortisand Model AWT1-20-SI-SK Filtration Unit

MILLIPORE 10" LONG X 3/4" PORT DURAPORE IONPURE STAINLESS FILTER CVGL011T

MILLIPORE 10" LONG X 1/2" PORT IONPURE STAINLESS FILTER HOUSING SANITARY

MC1000 TORIT/DONALDSON TWO-STAGE MIST COLLECTOR - #27808

64 DONALDSON/TORIT MIST COLLECTOR - #27810

64 DONALDSON/TORIT MIST COLLECTOR #27809

84 DONALDSON/TORIT DRY FILTER TYPE DUST COLLECTOR - #27814

FastCap RCV-0 Professional Workplace Remote Control Vacuum, Channel 0

Rosedale Screen Filter Housing #412114P2500CBNPB W/ Indicator 500psi 1 1/2" NPT

Ronningen-Petter Bank Canister Multibag Filter 3 Bank System

People who viewed this item also vieved

ARO SS Pneumatic Piston Pump, Sanitary SS Pump

E-Pak Machinery Head Molten Liquid Gravity Filling Machine

(4) 15/16" ALUMINUM DRIVE FLAT BELT PULLEYS-3/8" WIDE WITH A 5/16" CENTER

Quadro-Ytron YO Jet Mixer Daniel Tikusis 707-330-9227

LIGHTNIN 2.3HP MIXER, RPM 1740, FR 182YZ, V 208/230/460, SN: F1I03092138, NEW

52" x 52" Portable Tank Platform with forklift pockets

PREMIER Disperser EHP-7-5 (27327)

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies