US $9.00

Directions

Similar products from Instruction Manuals for Metal Cutting

Cincinnati Milacron Operating Manual 91202620A 500 & 750 VMC with CNC Controls

Cincinnati Milacron Parts Manual 91203234 500 & 750 ERO VMC ACRAMATIC A2100E

Cincinnati Milacron Programming Manual 91202621A 500 & 750 VMC with CNC Controls

Cincinnati Milacron Programming Manual 91202938C SABRE/ARROW ACRAMATIC A2100E

Cincinnati Milacron Service Manual 91202587A 500 & 750 VMC with CNC Controls

Okuma 8807-34 Software 8 in FLoppy Disk Set for MC-4VA VMC with 0SP5UUUM-G NC

Van Norman Operator Manual No.16 Ram Type Milling Mach. (Inv.18026)

LATHE 14-40 msc machine tool division 14-40g gap bed lathe +extras

kearney & trecker AXIS DRIVE manual FIRST EDITION 1978

TOS Technical Instruct Centre Lathes SN 40-SN 45-SN 50 (Inv.18028)

Cincinnati # 2 Cutter and Tool Grinder Operator's Instruction Book 1940 ORIGINAL

1920 Catalog— Cleveland Machine & Manufacturing Co—Power Presses 1920 ORIGINAL

1910s Secrets of MAKING Rifle BARRELS - Machinery's Industrial Secrets - reprint

IKEGAI A-20 LATHE INSTRUCTIONS & ELECTRICAL MANUAL

Metalwork for Craftsmen (1942) - Plans for Sheet Metal Work - republication

Haas Mill CNC Programming Training Manual *901

Milling Machine Practice: Cincinnati Co booklet (Lindsay how to book)

People who viewed this item also vieved

CAREGIE STEEL CO.,PA - 1923, engineers architects bridges cars ships, buildings

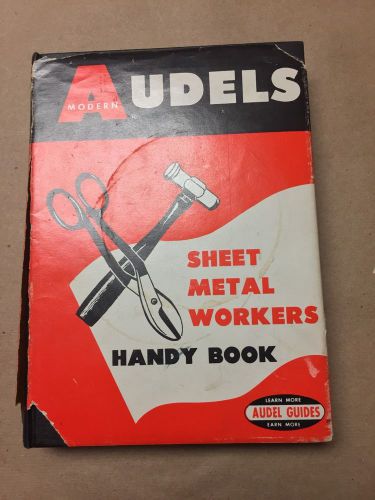

Audels Sheet Metal Workers Handy Book Hardcover 1967 Printing DJ FREE SHIPPING

Procedure handbook of arc welding, design and practice / Lincoln Electric / 1937

Machinery"s Handbook 24th Edition -Hardcover

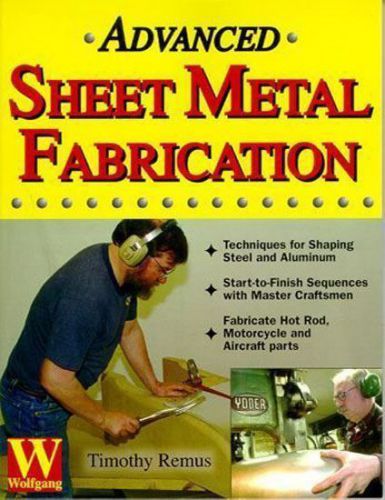

ADVANCED SHEET METAL FABRICATION ENGLISH WHEEL

Bridgeport Discovery 308 Maintenance Manual

Mori Seiki CNC Lathe SL-2 Mori Yasnac Instruction Operation Maintenance Manual

5 Republic Alloy Steels Booklets on Processing Steel 1961 lot 1

1943 MODERN MACHINE SHOP TRAINING VOL 1 NATIONAL SCHOOLS BOOK

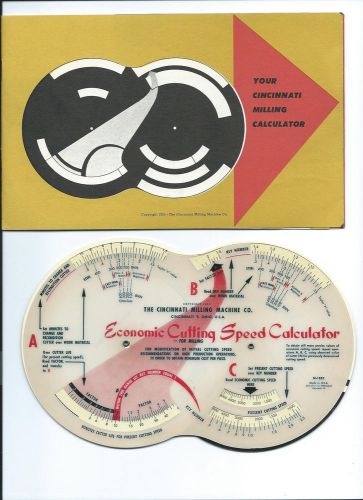

ORIGINAL 1955 CINCINNATI MILLING CALCULATOR WITH BOOKLET

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies