US $5,500.00

Directions

Similar products from Air Compressors

INGERSOLL RAND 4000 VERTICAL 60 GALLON 5 HP AIR COMPRESSOR

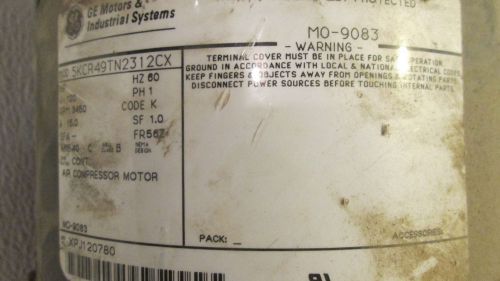

GE Air Compressor Motor*5KCR49TN2312CX*Sears Craftsman? 5.5 hp works

Emglo Air Compressor Pump, 1 stage, 2 cylinders

Quincy 20 HP rotary air compressor

1998 Quincy QSI-500 Rotary Screw Air Compressor 125 HP Baldor Motor 6110 Hrs

Ingersol Rand model 185 towable air compressor

NOS Thomas Model NO. 900-59-A Compressor E46046 115V 60HZ 2.9A Motor 600107B

Antique/Vintage DeVilbiss Air Compressor

VINTAGE DEVILBISS AIR COMPRESSOR TYPE 501 TESTED 115 V,60 Cycle 1.5 AMP

ARO C38221-600 Filter/Regulator and Lubricator, 58 cfm

RED HUSKY 60 GAL. COMPRESSOR--reduce price

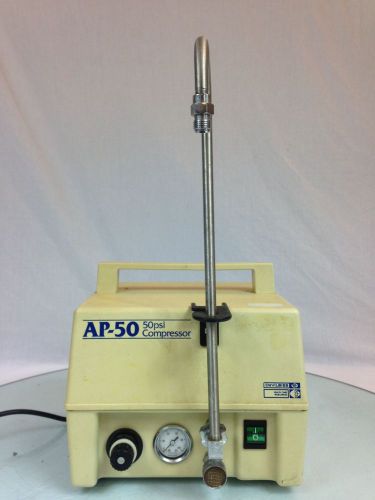

DeVILBISS AP-50 50psi Compressor

New out of box Dayton 3 stage air compressor pump 2 stage

People who viewed this item also vieved

Venco Conversion Dump Hoist VC620-DM

SIZE 3 Acrow Prop Post Shore Strong Acro Props 2000kg load Adjustable Steel Jack

DeWalt DW402 Corded Electric 7.5A Small Angle 4 1/2" Grinder Type 5 Paddle Switc

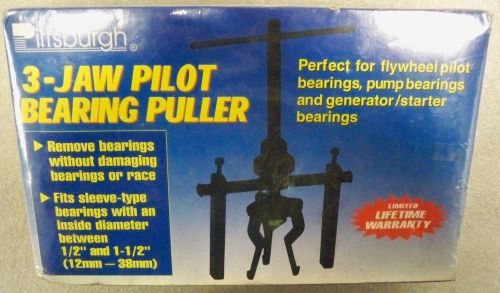

Pittsburgh 3-Jaw Pilot Bearing Puller Lifetime warranty Item #04876

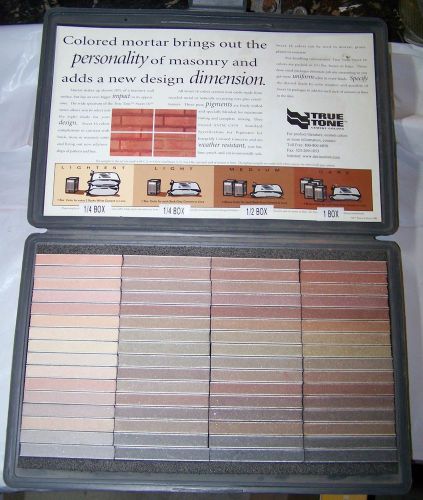

True Tone Color Pigment for Mortar Cement Sample Kit for Davis Colors

Dewalt DC515 18V Cordless Battery 1/2 GAL Vacuum Portable Wet/Dry 18 Volt

Generac Assy PCB R-200B Control Board 3600 RPM 2.4L Part# 0G8455DSRV

Bosch Double Insulated 1210 Die Grinder- Used

Powers P3600 Powder Actuated Fastening Tool Fastner in Case

Chicago Pneumatic MS695 Compaction Tamper, 3,330 LB Force

Gladiator GAWB65RWBG Starter Suite 65-Inch Rubberwood Top Workbench NEW!

Toro Stone Mixers Kit Bearing Seals For Morter Mixer Stone # St23432 1 Qty NEW

MASTER APPLIANCE HAS-043K Heat Gun Element Kit NEW, FREE SHIPPING, $4C$

Generac 200 Amp 600/480Vac Transfer Switch

DEWALT 487268-00 SPRING GUIDE FOR DEMOLITION HAMMER

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies