US $32.95

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | Saati |

| MPN | Chromaline Ulano Kiwo Murakami Emulsion | ||

| Model | Textil PV | ||

| Country of Manufacture | United States |

Directions

Similar products from Stencil Printing Tools & Accessories

silk screen printing press 4 colors 4 station equipment screening

2012 SummitDTG Direct to Garment printers (ALI #103337)

CD / DVD Silk Screen Printer 4 station Kamman

Newman Vector R Flood Bar Pink / newman roller frame

1 pc 14"(35cm) Emulsion Scoop Coater Silk Screen Printing Scrape Aluminum edge

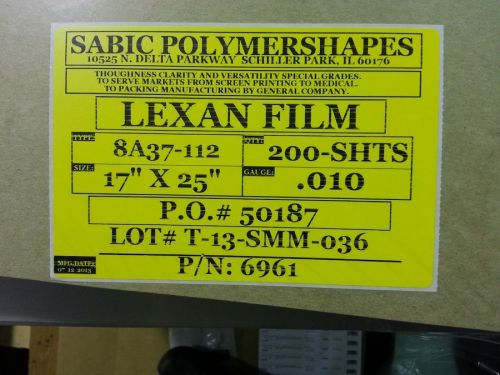

Brushed Lexan Polycarbonate Sheet .010" 17" x 25" - (100 Pack) Sabic 8A37

hydrographic activator no mixing required

Silk Screen Tension Meter For Polyester Mesh Nylon net Terylene High Precision

Saati Print Register Check RC18 3-Mil PCB Laminating Film 18"x200yd,100yd & 50yd

Pre-Stretched Frame Squeegee Scoop Coater 4 Color 4 Station Screen Press DIY Kit

screen printing equipment- silk screening printer dryer press flash- MICHIGAN

Semi-Automatic Screen Printer for Glassware

2 used screen printing screens, 110 line 14 x 18 (lot 13)

Custom Screen Printed T-Shirts 24 White Printed 1 color Front or Back

770 series Printa System Screen Printing Machine

American Screen Printing Press. Large Format.

REM Model 2240 Tabletop Splitter Reminder.

18x18 Flash Dryer Silkscreen T-shirt Printing Curing

New Heavy Duty Screen Printing Curing Ink T-shirt Heavy Duty Flash Dryer Unit

People who viewed this item also vieved

Crown roll leaf hot stamping foil, pink, 400ft

Kingsley Machine type - 18PT. Goudy Cursive - hot foil stamping machine

Crown roll leaf hot stamping foil, 400ft

New Stock Electric Foil Paper Cutter/ Gold Blocking/Hot Stamping Cuting Machine

Mini Laser Engraving Machine DIY USB Cutting Printer Engraver Logo Marking

GCC LaserPro C180 Laser Engraver Laser Cutter Etcher

New Hermes Engraving Fonts 35-355 Monogram

Epilog Laser Engraver Legend EXT table motor

Carestream DRYVIEW Laser Imaging Film 35x43cm (125 Sheets) 8203150

BRITISH PENS - WILLIAM MITCHELLS SET NO 469 4 X SCRAPER CUTTERS - UNUSED

T-JET Direct to Garment DTG printer Tshirt printer

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies