US $14,999.99

| “These units were removed from a semiconductor fabrication plant in AZ by us. They are guaranteed to work.” |

| Brand | SAES Getters |

| MPN | PS4-MT50-R-1 |

| Model | PS4-MT50-R-1 |

Directions

Similar products from Tool & Machine Spare Parts

0010-13627, AMAT, APPLIED MATERIALS, ASSY, HIGH EFFICIENCY RF MATCH-BIAS

0200-00289, AMAT, APPLIED MATERIALS, CYLINDER, WAFER SUPPORT, SI COATED, 200MM

Teflon End Effector Wafer Carrier, 200mm Wafers -- Outstanding Condition

Phase-A-Matic Static Phase Converter, Heavy Duty, Horse Power 1-3,PAM-300

SMC MGPL12-25 COMPACT GUIDE CYLINDER 1.0 MPA 12MM BORE 25MM STROKE

Applied Materials 0021-11297 Outer Clamp Cover

Applied Materials 0021-13661 200mm Titan Head II Outer Housing Cover

Applied Materials 0021-77384 Flexure Gimbal

Applied Materials 0040-45801 200mm Profiler Outer Clamp

Applied Materials 0040-62864 Rev 002 300mm Weight Compatible Profiler Cover

Applied Materials 0040-76576 Rev 002 6-Port 300mm Profiler Housing

Novellus 1011371005566 033931-F IMS 225mm Shower Head

Novellus 10137165230 019341 132590N B 375mm Shower Head

Novellus 132590 B 15-Inch Showerhead 1011370906147

People who viewed this item also vieved

Plastic Speed Change Handle, 57in Length (IMP 81)

Eco-Fresh Hang Tag Air Freshener - Herbal Mint, 12 per Box (KRY EHTS72 HMI)

Old English Furniture Polish, 12.5-oz. Cans (REC 74035)

Lysol Neutra Air Fabric Mist, Crisp Linen, 9 Bottles (REC 82669)

40X-2000X Infinity Metallurgical Polarizing Compound Microscope w 2MP USB Camea

50X-1500X Metallurgical Infinity Microscope with 9.0MP Digital Camera Reversed

Basler A101 Industrial Vision CCD W OPTO 045-200055 f=35mm lens & IR Filter

Zoom Stereo Binocular Microscope Body Only 6.7X-45X

KLA-Tencor 373664 SP1 Distribution PCB Rev.BB working

Hitachi 568-5531 Sense-CN PCB working

ATI 2 Person Workstation/ Conveyor

Conveyor, Simplimatic Automation 8010

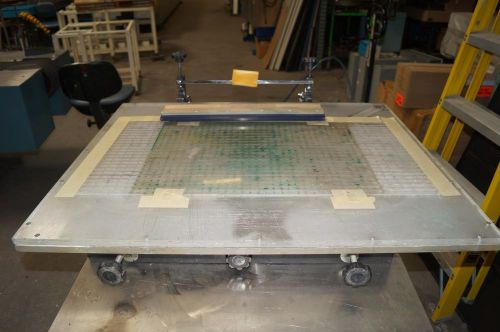

MANUAL SCREEN PRINTER WITH XY AND THETA ADJUSTMENTS

AG ASSOCIATES HEAT-PULSE 610 OVEN WITH COMPUTER

BLUE M POM7-256C-2 OVEN, MAX TEMP 343C / 650F ON FLOOR BASE

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies