US $15.95

Directions

Similar products from Instruction Manuals for Metal Cutting

Thermal Dynamics CutMaster 101 Plasma Cutter Service Manual *952

FANUC Series 16 / 18 for lathe OPERATOR's MANUAL

1980 Turning Handbook High Efficiency Metal Cutting GE GENERAL ELECTRIC CARBOLOY

VINTAGE ORIGINAL 1959 STEEL BENFIELD BENDERS MANUAL

VINTAGE ORIGINAL 1947 BUFFALO NO 15 DRILLS MANUAL

1943 How to Run Planers and Shapers - Tools, Typical Operations - reprint

Tricks & Secrets, Hints & Kinks of Old-Time Machinists Vol 3

1960s Kearney & Trecker Methods of Cam Milling NEW reprint

Tricks & Secrets, Hints & Kinks of Old-Time Machinists (1915-1916) Vol 2

DIY How to Build a GAS Fired CRUCIBLE FURNACE

Making the Small Metal Shop Profitable - Van Deventer - new Lindsay reprint

The Universal Sheet Metal Pattern Cutter Vol 1 Collectable Metal Work Book 1952

Yasnac MX 2 Operators Manual CNC System For machining Centers EXCELLENT COND!

How to Run a Lathe South Bend Lathe Works, Soft Cover, Vol 1 Ed 53, 1954

Gridley Multiple Spindle Automatic Screw Machines A Handbook for Operations

AVEY Operator's Instructions and Parts List for Machine No. 21793

Bardons & Oliver No. 7 Universal Turrent Lathe Parts Catalog

BAENESDRILL MAGNETIC COOLANT SEPARATER OPERATION - SERVICE MANUAL

People who viewed this item also vieved

Machinery’s Handbook 10th Edition-The Industrial Press-1941-Vintage -Collectable

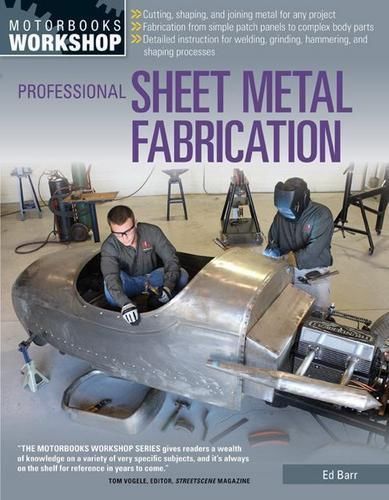

Sheet Metal Fabrication welding forming turning laser seams hammer english wheel

MACHINERY'S HANDBOOK 26 TH TWENTY SIXTH EDITION INDUSTRIAL PRESS BY ERIK OBERG

VINTAGE 1944 MACHINERY'S HANDBOOK 12TH EDITION MACHINE SHOP BOOK MANUAL

Machinery's Handbook Toolbox 28th Edition

MORI SEIKI MV-65 Manual, Electrical Circuit Schematic and Ladder Chart Diagram

MORI SEIKI MV Series Operation Manual, FANUC MY-M6, MV-Junior, JR, MV-45, 55, 65

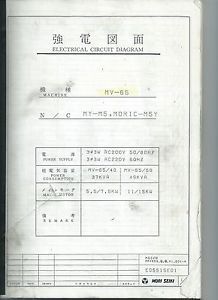

Mori Seiki MV-65 Electrical Circuit Diagram, Moric-M5Y, MY-M5, Fanuc

Okuma ELECTRICAL DRAWING MANUAL_CADET-V4020, A80001A_P-K770-004-E

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies