US $3,674.25

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Model | 2.2 |

| Country/Region of Manufacture | China | ||

| MPN | Does Not Apply | ||

| Brand | Meelko |

Directions

Similar products from Animal Feed

Small Electric Household Animal Feed Chicken Dog Cat Food Pellet Machine 220V

Home Manual Birds Fishing Bait Granulator Pellet Maker Animal Food Maker

3KW Farm Animal Pellet Mill Machine Chicken Duck Feed Pellet Mill Machine 220V

220V 3KW Farm Animal Pellet Mill Machine Chicken Duck Feed Pellet Mill Machine

Chicken Duck Feed Pellet Mill Machine 220V 3KW Farm Animal Pellet Mill Machine

1pc Farm Poultry Animal Pellet Mill Machine Chicken Duck Pig Feed Pelletizer

HL-MP47A Plastic Milk Sampling Bottle Container Sampler For Milking Machine Far.

HL-MP47A Plastic Milk Sampling Bottle Container Sampler Diverter For Milking .

Farm Poultry Animal Pellet Mill Machine Chicken Duck Pig Feed Pelletizer New

Farm Poultry Animal Pellet Mill Machine Chicken Duck Pig Feed Pelletizer New

Small Industrial Pellet Mill ROLLER ROTATING 7.5KW 150 kg/H Pellet Perss

Small Industrial Pellet Mill ROLLER ROTATING PTO 500 kg/H Pellet Press factory

Small Industrial Pellet Mill ROLLER ROTATING PTO 370 kg/H Pellet Perss Factory

Small PELLET MILL line 600Kg/H for balanced animal feed- milling- mixing

Small Industrial Pellet Mill ROLLER ROTATING PTO 150 kg/H Pellet Perss factory

Small Industrial Pellet Mill ROLLER ROTATING 22KW 370 kg/H Pellet Perss

Ice Scoops - Aluminum - 38oz. - 1 Piece

PELLET MILL 15kw ELECTRIC ENGINE MKFD260B DIE 3 PHASE 6mm

5-Piece Bovine Nose Weaner, Farm Cattle Breeding Equipment, Thickened Plastic

PELLET MILL 22kw ELECTRIC ENGINE PELLET PRESS 3 PHASE USA STOCK (5mm pork)

People who viewed this item also vieved

Farrier hoof Care tools,Shoe Puller and Spreader

250 Watt Infrared Bulb for Heat Lamp Barn Warming Long Lasting Extra Warm Red

![Adult Bee Jacket Beekeeper Jacket Zip Round Sheriff Veil Yellow [XXL] A1218N003](/_content/items/images/35/3385835/001.jpg)

Adult Bee Jacket Beekeeper Jacket Zip Round Sheriff Veil Yellow [XXL] A1218N003

![Adult Bee Jacket Beekeeper Jacket Zip Round Sheriff Veil Yellow [XL] A1218N003](/_content/items/images/36/3385836/001.jpg)

Adult Bee Jacket Beekeeper Jacket Zip Round Sheriff Veil Yellow [XL] A1218N003

100sets NEW Orange Sheep Goat Ear Tag Lable Identification With Number Eartag

100 sets NEW Green Sheep Goat Ear Tag Lable Identification With Number Eartag

BEST PRICE milk cream centrifugal separator 100l/h plasti?

Inflation Shut Off Plug - With Chain - Rubber - Brand New

1-LGHT ELEC FNC TSTR FI-SHOCK INC Electric Fence Accessories A1LVT-FS*

Pet Deterrent Fence Control ZAREBA Electric Fencers/Energizers K9/4009

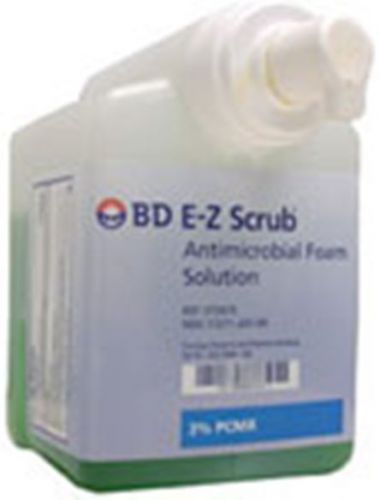

Vet Office BD E-Z Scrub™ Antimicrobial Hand Foam Solution 3% Chloroxylenol 32oz

Vet Supply J0042X Dental Root Tip Pick Vet Horse Dog Cat Bone Teeth Extraction

8Gal Red Multipurpose Bucket FORTEX/FORTIFLEX Feeders/Waterers MPB-40R Red

2Bushel Red Barn Bucket FORTEX/FORTIFLEX Feeders/Waterers MB-70R 012891270028

Large egg basket. Little giant. Holds 8 dozen eggs

HOW TO RAISE CHICKENS - Over 100 Books on CD, including Hatching Eggs Coop Info@

4 PCS Replacement Top Quality Steel Farm Sheep Clippers Blade Goat Shearing

Curving Blade Replacement For Electric Clippers Farm Livestock Sheep Goat Shears

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies