US $39.99

Directions

Similar products from Measuring Gage Blocks

MACHINIST LATHE MILL Machinist Lot Of Tool Makers Gage Gauge Block s Ground

Fowler 36 pcs Gage Block Set - Grade 2

QUICK REFERENCE SIZES BLOCK FROM 1/4" TO 2-1/2" lay-out mills SURFACE GRINDER

MACHINIST'S LOT QUALITY ASSORTED SIZE GAGE BLOCK S PRATT & WHITNEY MITUTOYO ETC.

Mitutoyo 293-831 Digimatic MDC-MX Lite Outside Micrometer - 0-1"

Machinist Unfinished Set Up Blocks, Block, Metalworking Tool, Tools

LUFKIN ADJUSTABLE PARALLELS SET OF 6 PCS.

Starrett / Webber Gauge block gauge setting set

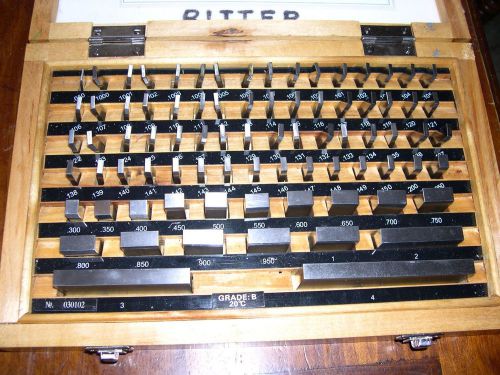

GAGE BLOCK SET 81 PCS. GRADE B

Mitutoyo Gage Block Set 516-930

MITUTOYO MACHINIST GAUGE BLOCK SET 516-612

MACHINIST TOOL LATHE MILL Brown & Sharpe # 559 Tool Makers Square Block

3~Lufkin Adjustable Parallels~915 C, D, & E

4 STARRETT ADJUSTABLE PARALLELS A,C,D,&E

MACHINIST TOOLS LATHE MILL Starrett Webber Gage Block Set RS92A1 92 PC

MACHINIST TOOLS LATHE MILL DoAll Gage Block Set Grade B 37 PC

MACHINIST TOOL LATHE MILL Starrett Adjustable Parallel Block Set in Case

Starrett Radius Gauge Set No. S167C in Original Case

Fowler 53-672-081 Gage Block Set 81 piece .05-4.00" Machinist

Simonds England CARBIDE GAGE BLOCK SET 81 PCS MILLING GRINDING MACHINIST

People who viewed this item also vieved

FOWLER 52-085-040 40" /1000mm Master Vernier Inside Outside Caliper 1Y Stainless

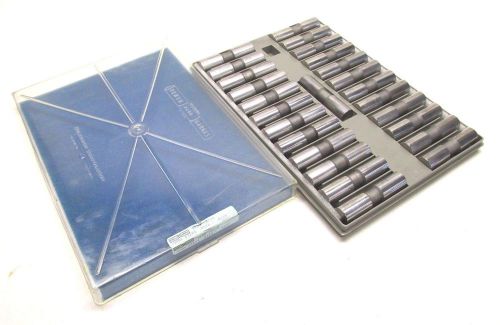

(92) Plug Gages, Gage, Machinist Inspection, Go, No Go, Up to .750", w/ Handles

25-PIECE DELTRONIC TP25 .8125" PIN GAGE SET - .0001" STEPS - .8113" to .8137"

Federal Dial Indicator P61 .01mm Excellant condition

Indicator Swivel double Post Snug 3/8 and 1/4 combo lot of 4 plus 3/16 snug

MITUTOYO 4-5" OUTSIDE MICROMETER NO. 103-219A .0001 GRADS STK 9243

STARRETT NO. 436 12"-13" OD Outside Micrometer

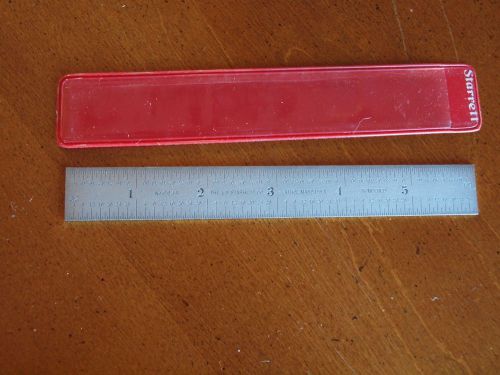

NOS Starrett Satin Chrome Rules C604R-6 spring tempered ... 3 available w/box

SHINWA 30cm Pick Up Ruler Metric Machinist Carpenter Scale Rule 13134 Japan

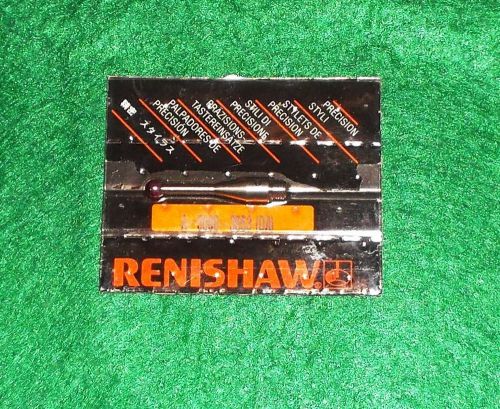

Brown and Sharpe CMM Ball Probe

Renishaw Precision Styli A5000-3553

DOALL 18” x 24” x 3” Granite Plate Black Grade B

DOALL 18” x 24” x 2” Granite Plate Black Grade B

C-BRAL DIAMOND PENETRATOR WILSON MECH INSTR HARDNESS TESTER

5/8-18 UNF-2A Go PD .5875 GF Ring Gage Machinist toolmaker Inspection tools

CULLEN MFG ERICK MAGNA-HOLDER MODEL 200B NOS

Enco Magnetic Indicator Base USA

Starrett Combination Machinist Square 12" No. 4R Grad Hardened

Craftsman 4 Piece Combination Machinist Square 12" Protacter Center Finder

Starrett 47 Universal Bevel, 6" Blade Length

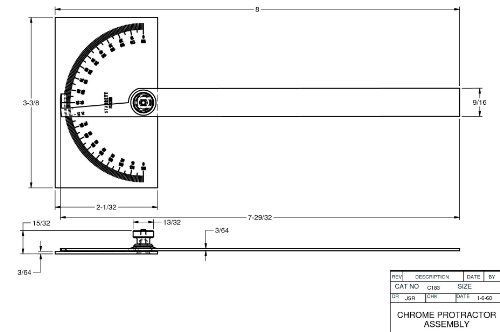

Starrett C183 Steel Protractor with Rectangular Head

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies